A processing device and processing method for a channel steel slotting and bending assembly

A processing device and assembly technology, applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems that the slotting position and dimensional accuracy are difficult to meet the requirements, affect the quality of the assembly, and the cutting quality is poor, so as to achieve the guarantee Processing accuracy and follow-up process, avoiding burrs and uneven incisions, and improving processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

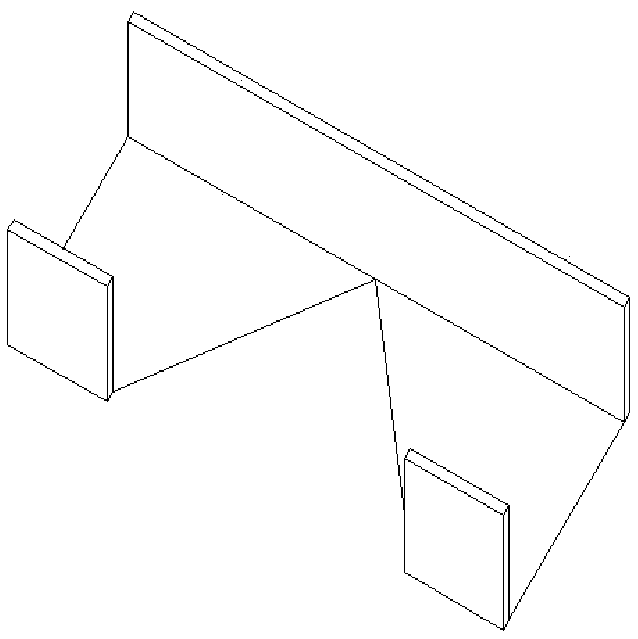

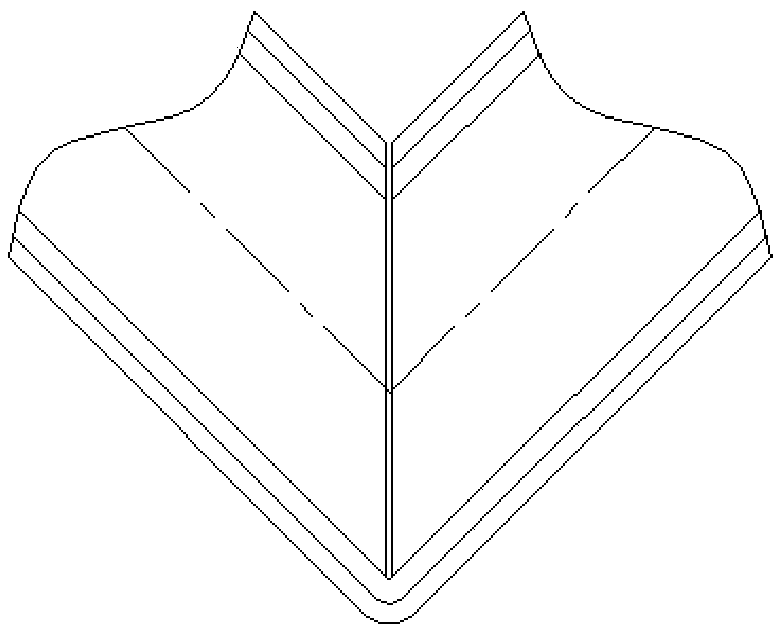

[0052] In conjunction with the accompanying drawings, a channel steel grooving and bending assembly processing device of this embodiment includes a rectangular grooving processing die, a triangular grooving processing die and a bending processing die, and the rectangular grooving processing die is placed on the side of the channel steel 5 Process a rectangular grooving, process a triangular grooving at the bottom surface of the channel steel 5 by the triangular grooving processing mold, thereby realize the processing of the upper grooving of the channel steel as shown in Figure 1, significantly improve the processing efficiency and the efficiency of the channel steel assembly The processing quality can avoid the phenomenon of burrs and uneven incisions, and ensure that the quality of the final assembly meets the requirements; the channel steel after grooving is bent through the bending processing mold.

[0053] Figure 1- Figure 5 As shown, the rectangular grooving mold of the...

Embodiment 2

[0057] A channel steel grooving and bending assembly processing device in this embodiment includes a rectangular grooving processing die, a triangular grooving processing die and a bending processing die, wherein:

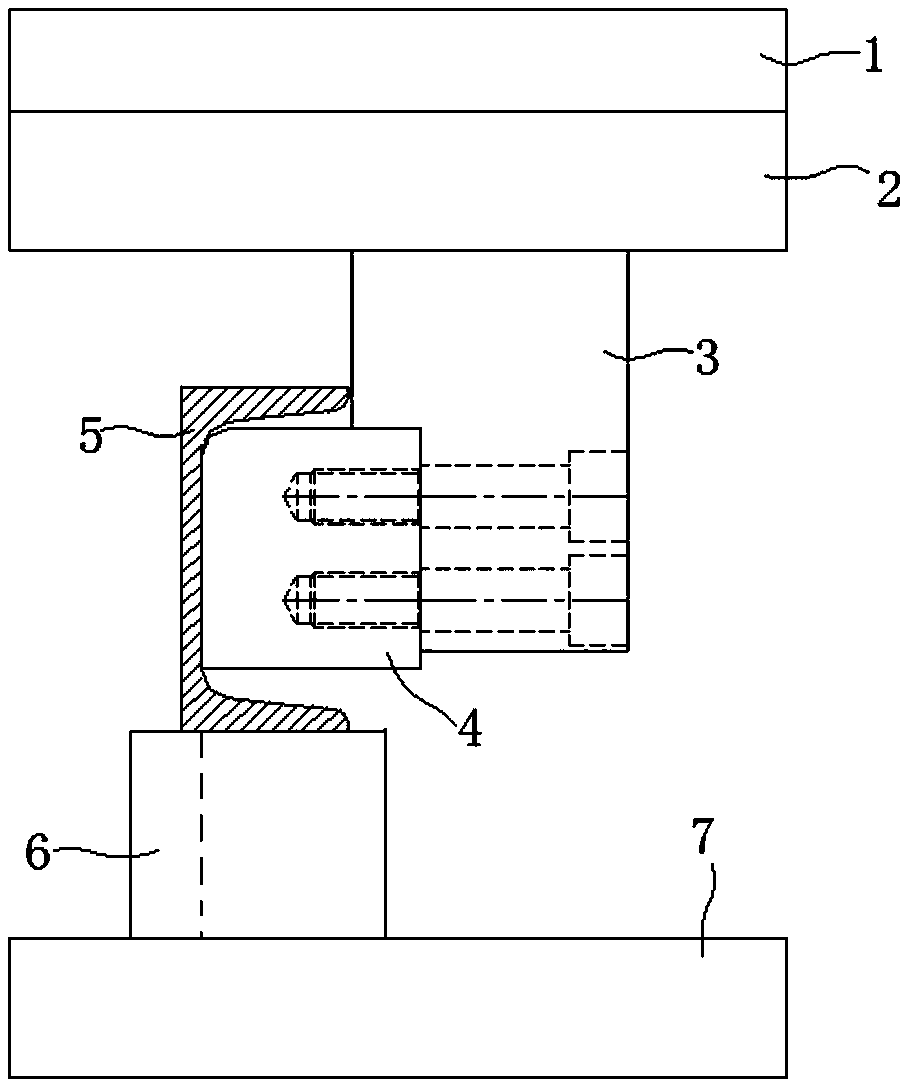

[0058] Such as Figure 2-Figure 5 As shown, the rectangular grooving processing mold includes a first moving knife 4 and a first static knife 8, the first moving knife 4 is processed into a cuboid structure and is positioned above the first static knife 8, and the first static knife 8, the first moving knife The knives 4 are all made of 9CrSi material with a hardness of HRC=55-57, which can effectively ensure the strength and toughness requirements of the knives, prevent the knives from breaking and deforming during the shearing process, and prolong the service life of the knives. Among them, such as figure 2 As shown, in this embodiment, a positioning groove is processed on the first movable knife seat 3, and the side of the first movable knife 4 is installed in ...

Embodiment 3

[0067] The structure of the device for processing grooved and bent assembly of channel steel in this embodiment is the same as that in Embodiment 2.

[0068] A method for processing channel steel slotting and bending assemblies in this embodiment includes installing the rectangular grooving dies, triangular grooving dies and bending dies on the machine tool respectively, wherein the first static knife seat 6 and the second static knife seat 10 are installed on the machine tool table through the first lower template 7 and the second lower template 9 respectively, and the first movable knife seat 3 and the second movable knife seat (omitted in the figure) respectively pass through the first upper The template 2 and the second upper template (omitted in the figure) are fixedly connected with the connecting plate 1 on the machine tool. Firstly utilize the rectangular grooving processing die to process a rectangular slot on the side of the channel steel 5 to be processed, then use ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com