Material pulling structure of continuous progressive die

A technology of progressive die and drawing needle, applied in the field of stamping, can solve the problems of insufficient strength, affecting the efficiency and quality of stamping, and sending the material to the die.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

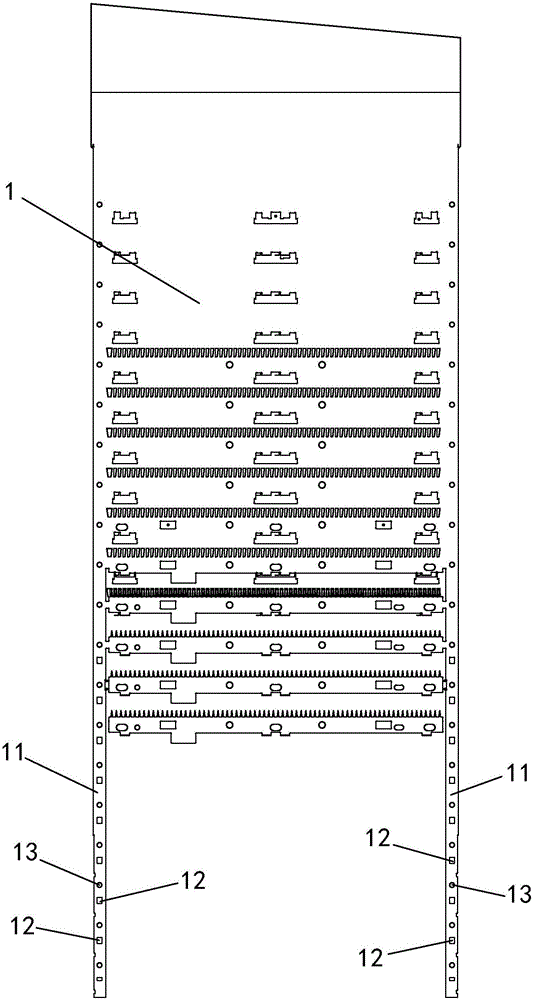

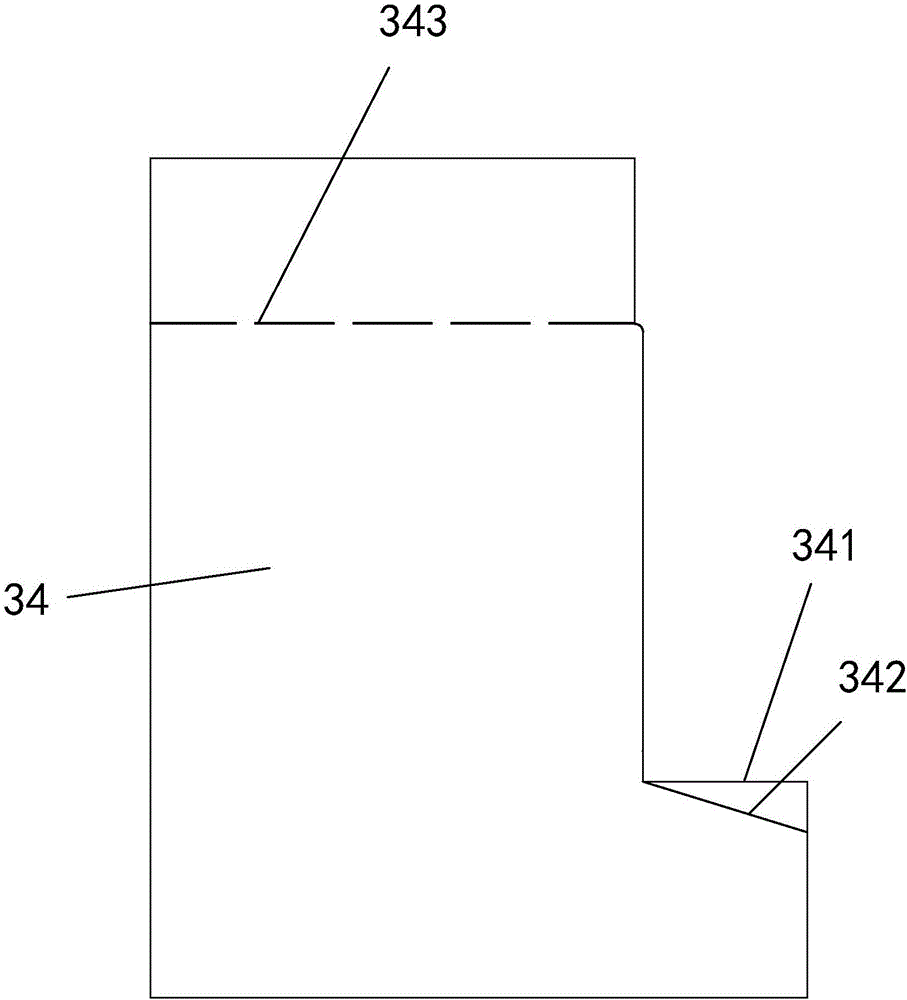

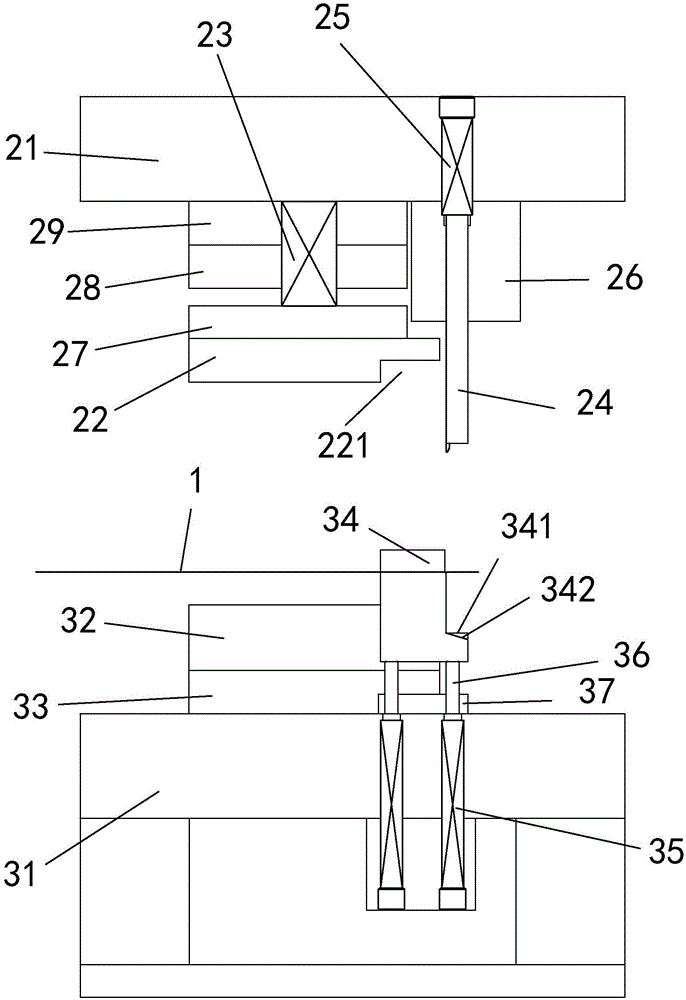

[0039] see Figure 1~Figure 9 As shown, a kind of drawing structure of continuous progressive die comprises material belt 1, lower mold and upper mold, and lower mold comprises lower mold base 31 and lower template 32, and lower template 32 is arranged on the top of lower mold base 31, and lower template 32 and the lower die base 31 are provided with a lower backing plate 33, and the upper die includes an upper die base, 2 and an upper stripping plate 22, and the upper stripping plate 22 is located below the upper die base 21, and the upper die base 21 and the upper stripping plate 22 An upper backing plate 29, an upper splint 28 and a back-off plate 27 are arranged sequentially from top to bottom.

[0040] The guide edges 11 on both sides of the material belt 1 are provided with drawing holes 12, and the drawing holes 12 are distributed at intervals in the length direction of the material belt 1, and the distance between adjacent drawing holes 12 is the same as that of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com