A New Reaction Arm

A reaction force arm, a new type of technology, applied in the direction of wrenches, power tools, screwdrivers, etc., can solve the operator's hand, wrist shoulder fatigue, affect the tightening accuracy, affect production and other problems, achieve compact structure, improve tightening accuracy, The effect of convenient positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

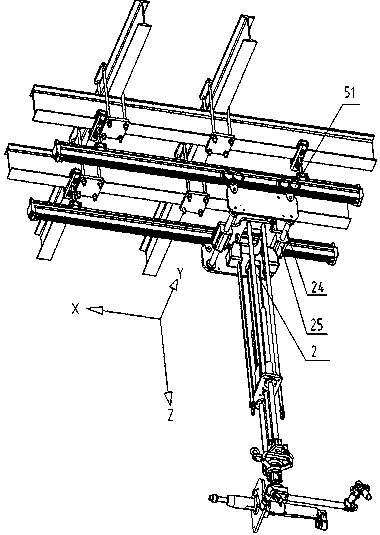

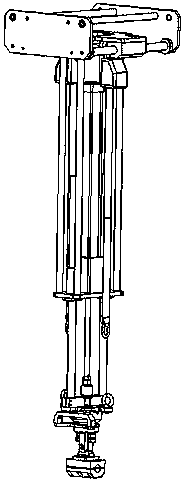

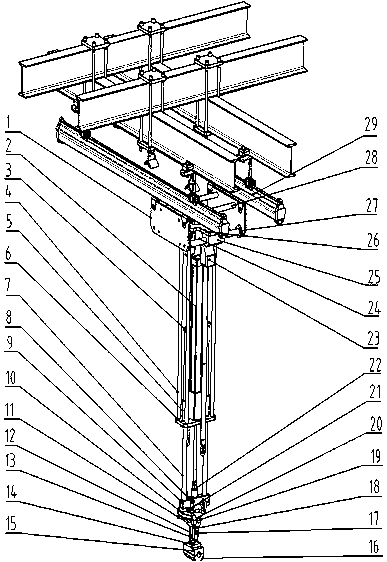

[0023] In order to further explain the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] see Figure 1 to Figure 12 As shown, this novel reaction arm includes KBK slide rail 29, suspension assembly and wrench box. KPK slide rail is connected with suspension assembly by pulley 51, and pulley 51 moves freely within the track length scope of KPK slide rail 29. The suspension assembly includes two side hanging plates 1, the hanging plates 1 on both sides are respectively connected with the KPK slide rail 29 through the pulley 51, and the first supporting shaft 28 and the second supporting shaft 24 are passed between the hanging plates 1 on both sides. connection, the limit ring 27 is passed through the two ends of the second support shaft 24, a linear bearing 25 is arranged on the second support shaft 24, a top plate 26 is connected to the upper surface of the linear bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com