Multifunctional vertically-seamless multiple-blade saw

A multi-functional, multi-blade saw technology, applied in the field of sheet metal processing, can solve the problems of the saw blade needing to be disassembled by the whole shaft, the specification cannot be adjusted or the adjustment is inconvenient, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

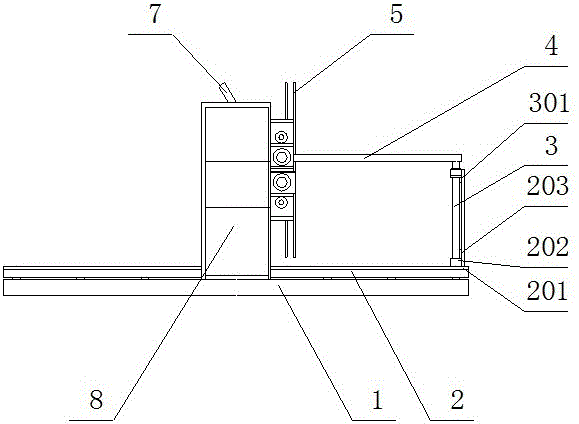

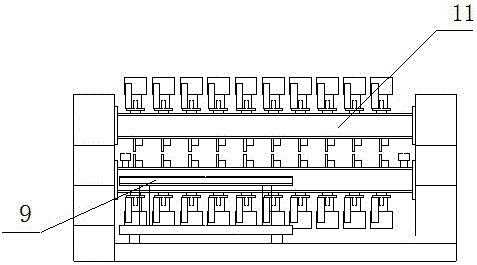

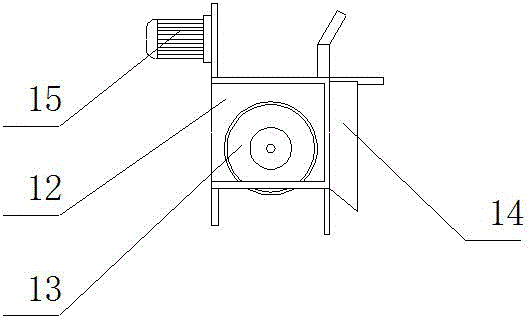

[0022] like Figure 1-4 As shown, a multifunctional up and down seamless multi-blade saw mainly includes an upper shaft assembly 11, a lower shaft assembly 9, an L connecting plate 14, a motor saw shaft seat 5, a motor 15, a saw shaft assembly 6, a saw Shaft splint 13, saw blade cover 12, tensioning wheel assembly 10, said L connecting plate 14 is connected with motor saw shaft seat 5, and said motor saw shaft seat 5 is equipped with motor 15, saw shaft assembly 6, saw shaft Splint 13, saw blade cover 12, tensioning wheel assembly 10, the upper end or lower end of the saw blade cover 12 is connected with a dust removal pipe 7, the upper shaft assembly 11 is connected with a large column 8, the upper shaft assembly 11 is provided with a lower shaft assembly 9, the lower end of the large column 8 is provided with a chassis 1, the upper end of the chassis 1 is provided with a support rail 2, and the upper end of the support rail 2 is connected with a guide rail 201, and the guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com