Forming method and production equipment of prefabricated panel with frame

A technology of production equipment and molding method, which is applied in the production field of industrial prefabricated components, can solve the problems of low production efficiency, large occupied area, high labor intensity, etc., and achieve the effects of continuous and efficient production, convenient cleaning, and simple and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, describe the best implementation mode of the present invention through preferred embodiment, the specific implementation mode here is to illustrate the present invention in detail, and should not be interpreted as the limitation of the present invention, without departing from the spirit and essence of the present invention Various changes and modifications can be made within the scope of the present invention, and these should be included in the protection scope of the present invention.

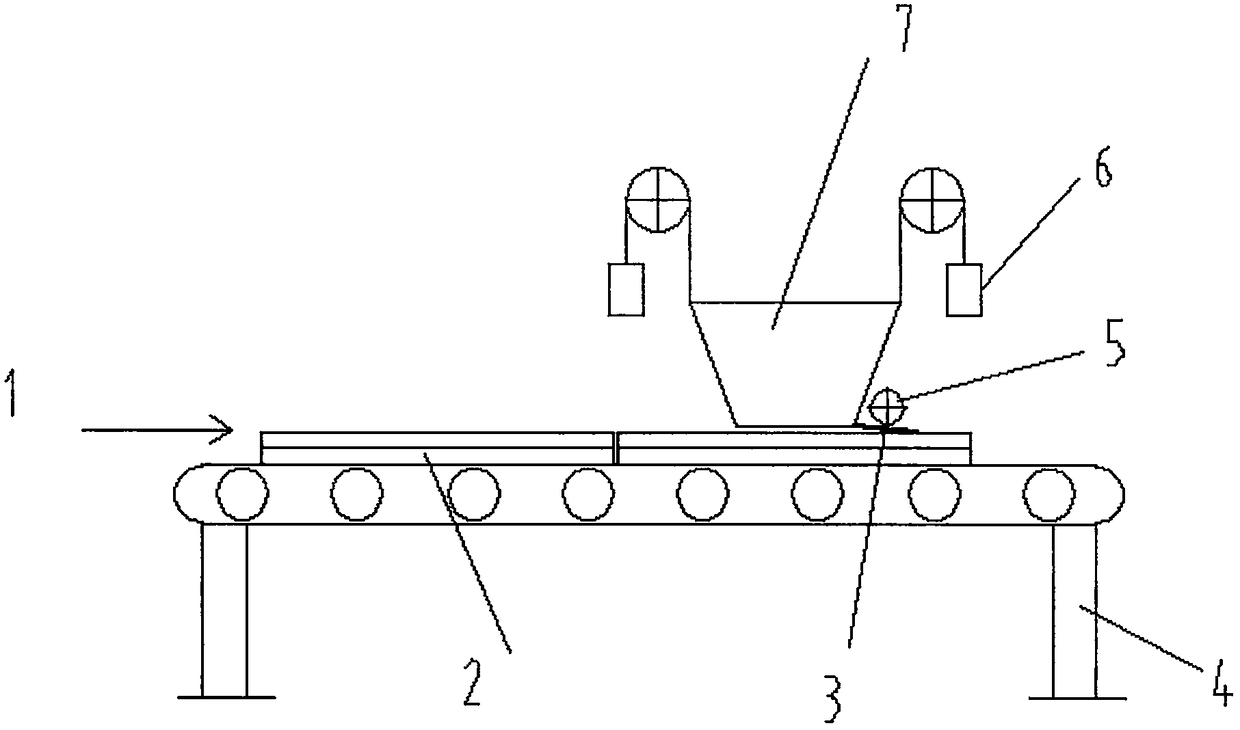

[0029] see Figure 1-2 , The invention provides a production equipment for a prefabricated panel with a frame. The production equipment of the prefabricated panel with frame includes:

[0030] Cloth hopper 7, which is arranged above the following combined mold frame;

[0031] Scraping mechanism 3;

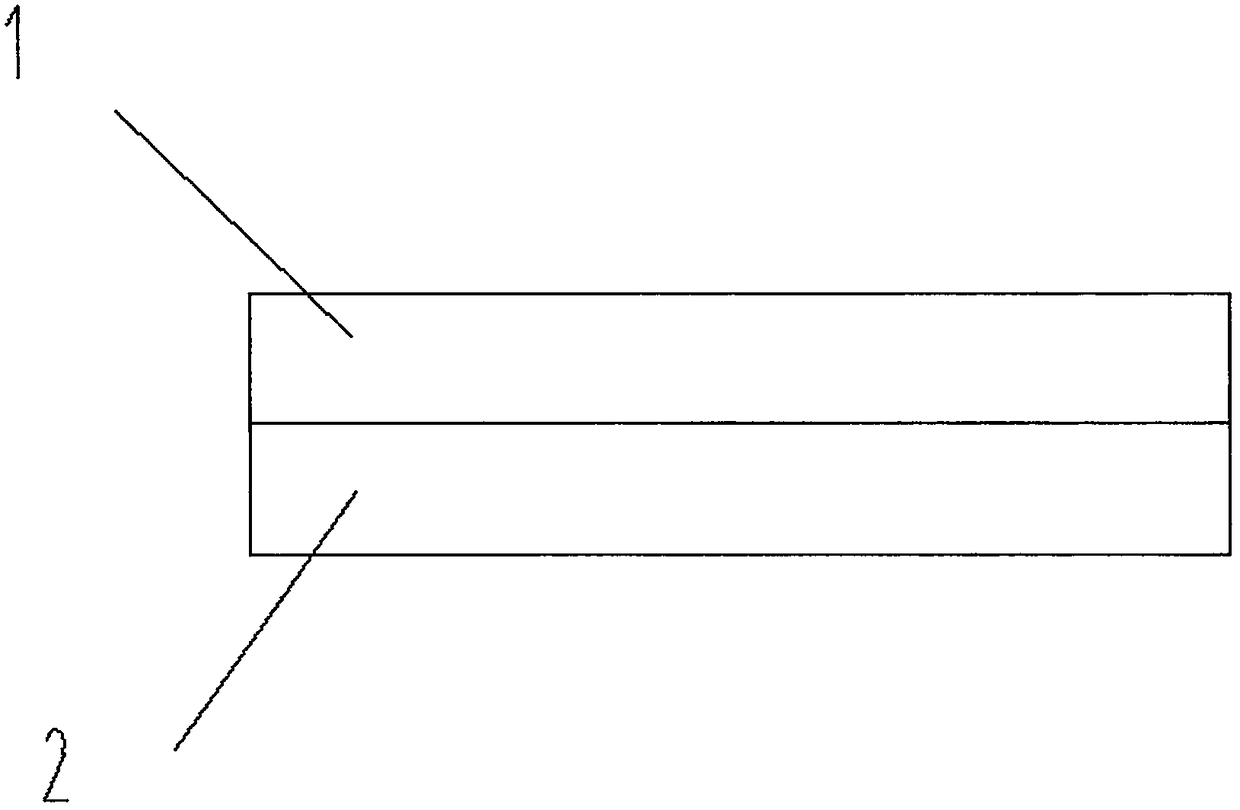

[0032] A combination mold frame composed of bottom mold 2 and component frame 1;

[0033] Bottom mold support frame 4; And

[0034] pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com