De-molding and resetting device for injection molding of herringbone gear

A technology of injection molding and herringbone gear, applied in the field of injection molding demoulding and reset device, can solve the problems of easy wear, poor molding quality, large core resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0039] This embodiment is used for injection molding mould, and mold is installed on the horizontal injection machine.

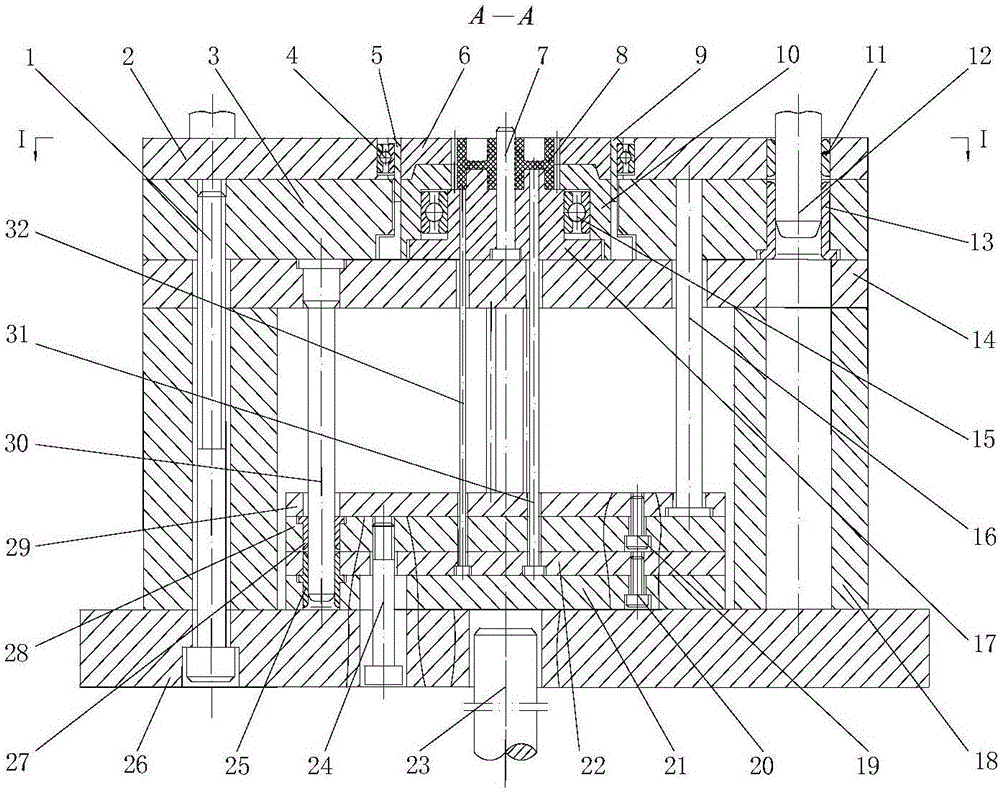

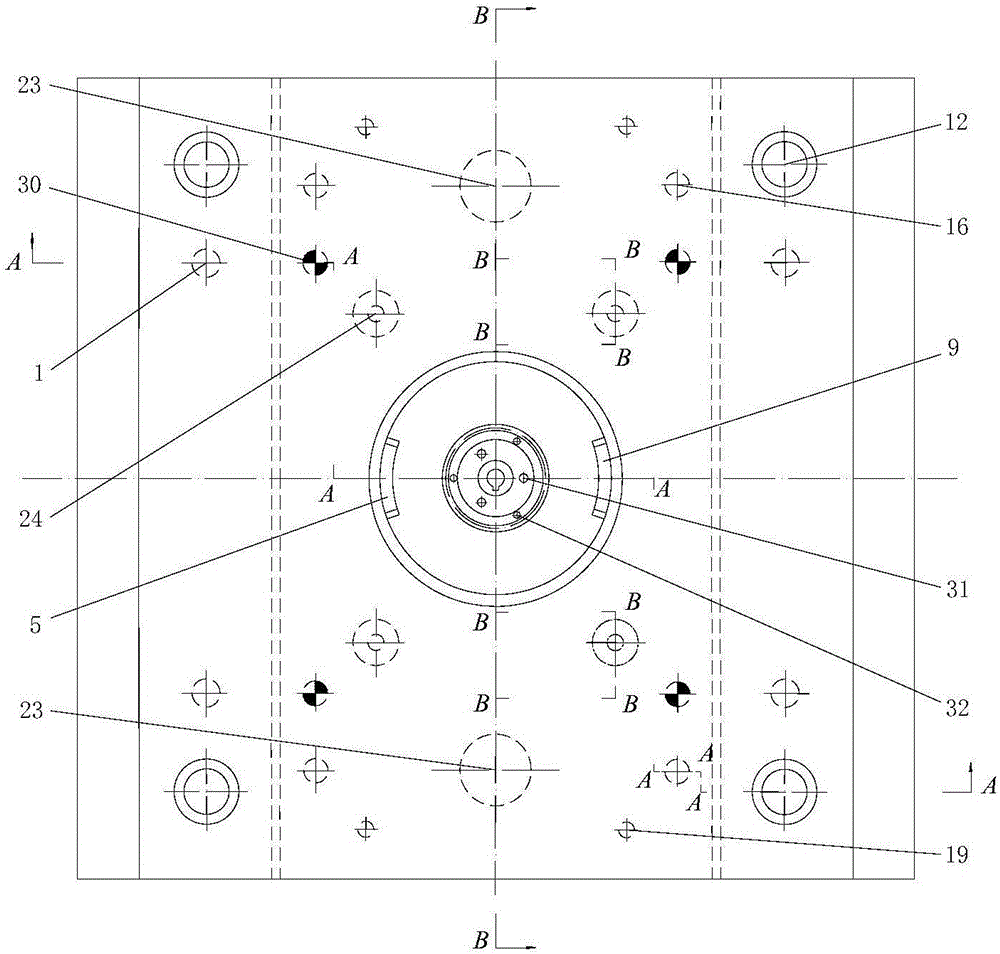

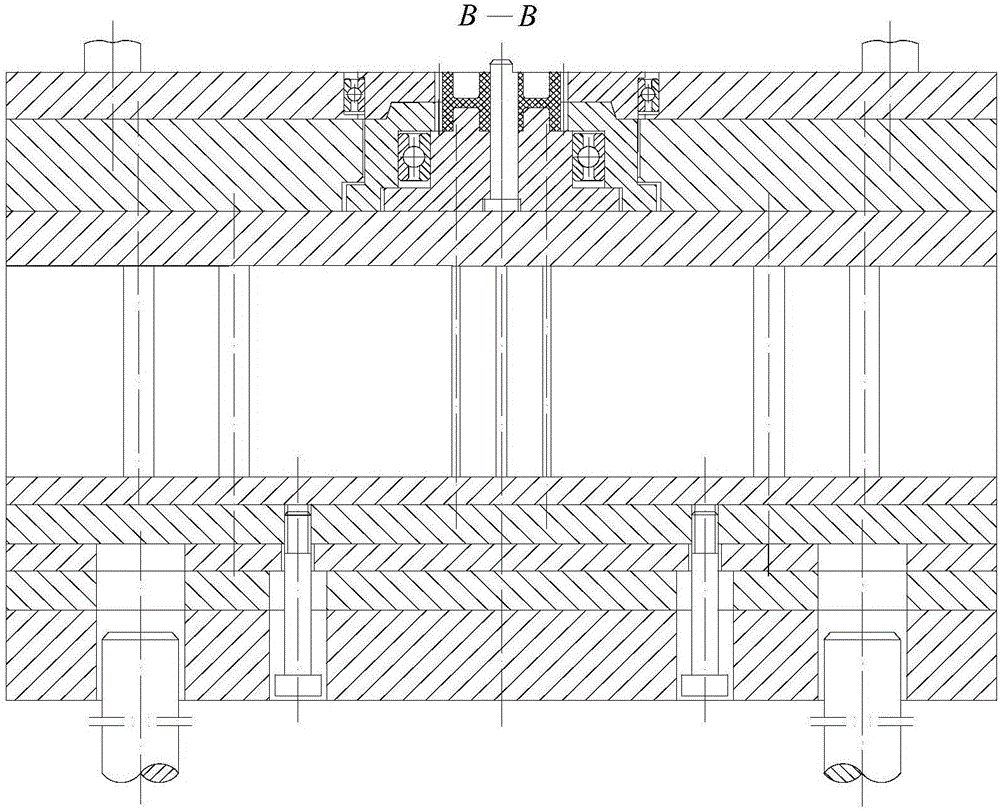

[0040] After the injection molding is completed, under the action of the mold opening mechanism of the injection machine, the movable mold part moves along the figure 1 The shown parting surface I-I retreats to the set position. figure 2 It mainly reflects the distribution positions of guide pillars, hexagon socket screws, helical gear cavities, positioning inserts, push rods, push plate guide pillars, connecting rods, ejector rods of injection machines and other parts. figure 1 is the A-A sectional view of the device, image 3 It is a B-B cross-sectional view of the device.

[0041] The device includes from top to bottom: cavity fixing plate 2, movable template...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com