A kind of 3D additive printing method of whole shoe upper fabric

A printing method and technology for shoe uppers, applied in printing, printing devices, etc., can solve problems such as uneven printing quality, failure to meet design strength requirements or aesthetic requirements, and improve printing efficiency, avoid glue spillage, and beautiful printing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

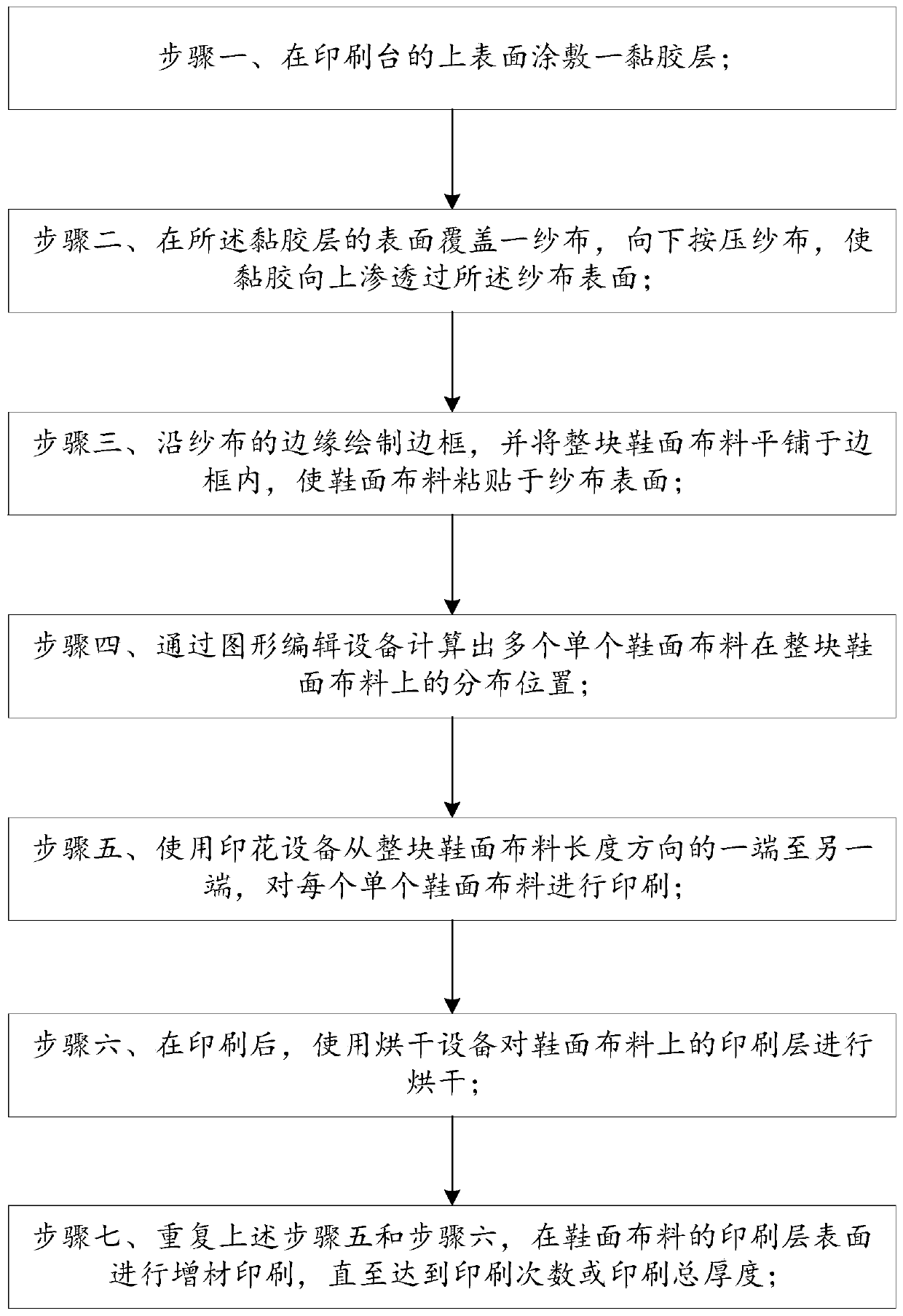

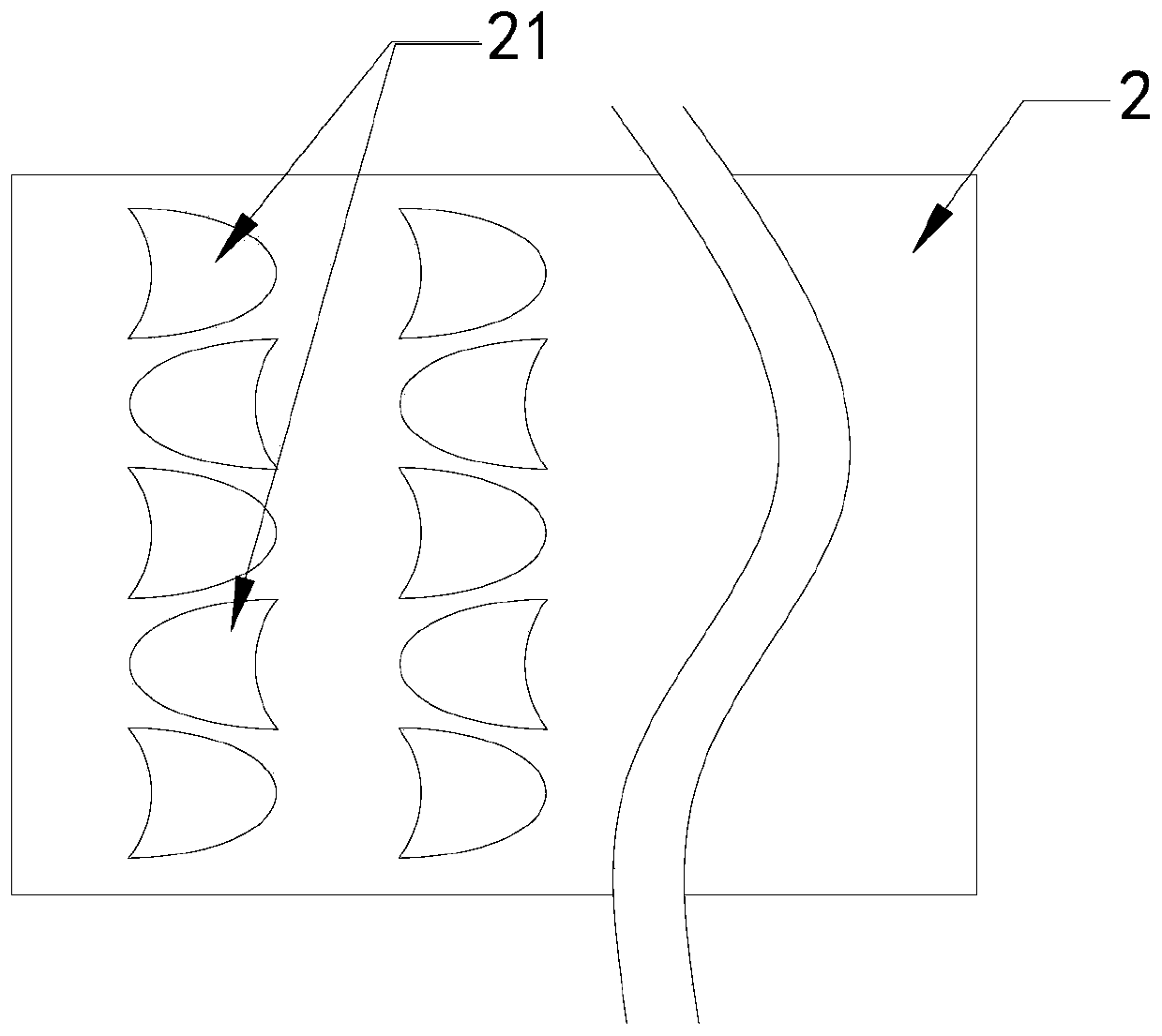

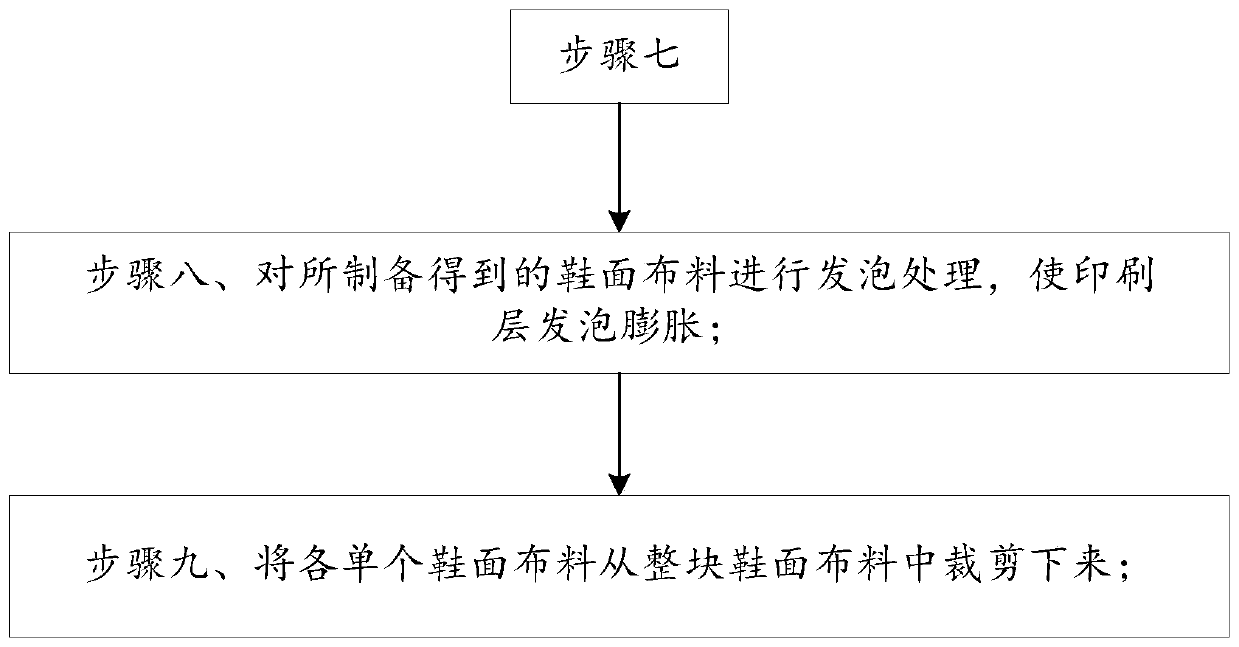

[0032] see figure 1 , this embodiment provides a method for 3D additive printing of a whole piece of shoe upper fabric, wherein the whole piece of shoe upper fabric refers to a long strip of fabric that has not been cut into the shape of the shoe upper, and is directly cut from a whole roll of fabric owned. The 3D additive printing method can be applied to various requirements such as the printing of reinforcing strips or reinforcing films of shoe upper fabrics. Specifically, the 3D additive printing method includes the following steps:

[0033] Step 1, coating an adhesive layer on the upper surface of the printing table. The printing table is a long table with a flat upper surface, and the printing operation of the upper cloth is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com