All-steel tubeless truck tire suitable for 5-degree tapered bead seat rim

A technology for tires and rims, which is applied in the field of all-steel truck tires without inner tubes, can solve the problems of reduced inflation pressure, air leakage at the bead, and the contact pressure between the tire and the rim cannot meet the tire airtightness requirements, etc., to improve the contact pressure, Effect of reduced deformation creep, good gas retention and related performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0017] The technical terms are defined as follows:

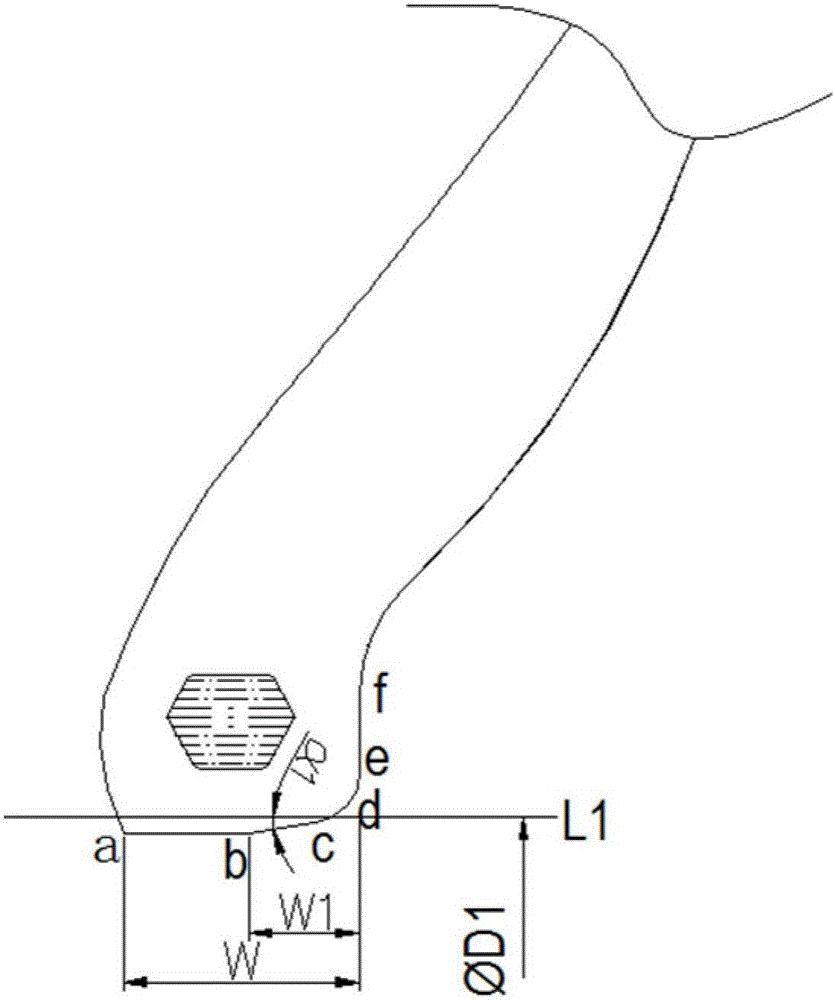

[0018] Such as figure 1 As shown, the bead profile of the tire is composed of bead bottom arc (abc), bead heel arc (cde) and bead side arc (ef), and a horizontal line L1 that defines the intersection of tangent line bc and ef is the bead of the tire Fitting diameter ΦD1, defining the tangent line (bc) of the heel arc (cde) relative to the horizontal line L1 to form a bead seat angle α1, defining the total width of the bead seat as W, the bead seat angle line bc and the heel arc ( The horizontal line width formed by cde) together is W1.

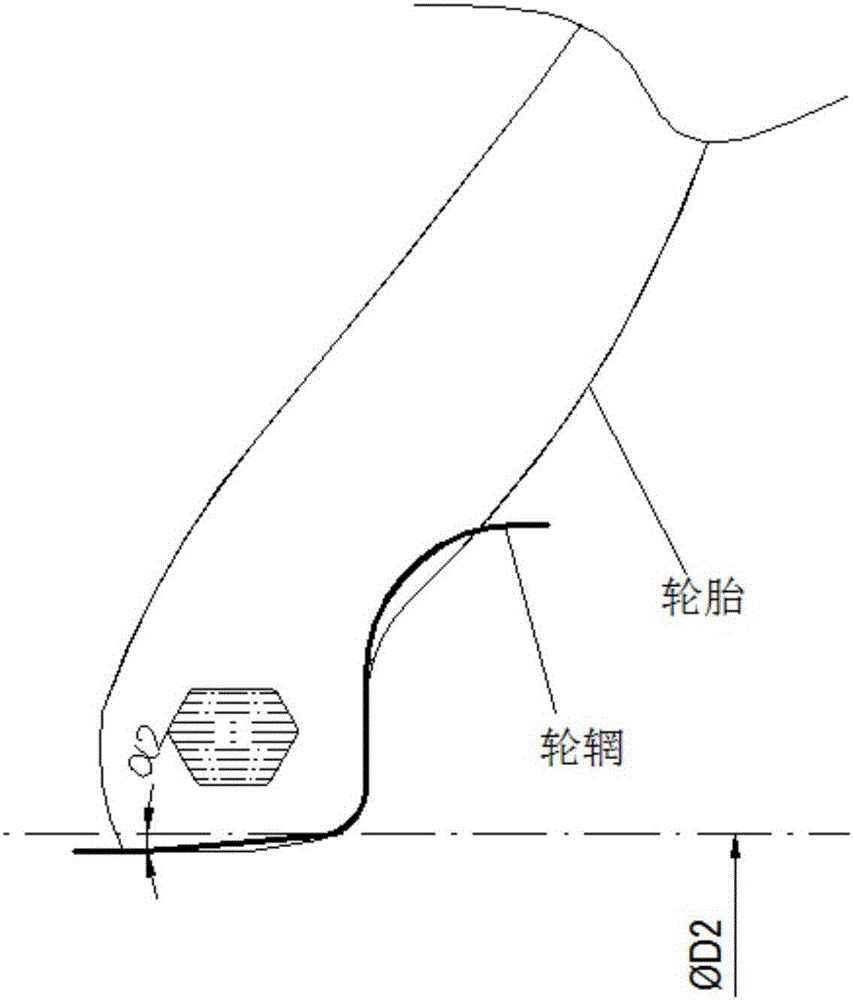

[0019] Such as figure 2 As shown, the nominal diameter of the rim is ΦD2, and the bead seat angle of the rim is α2.

[0020] Such as image 3 As shown, define the bottom diameter of the bead part of the tire bead as ΦD3.

[0021] Such as Figure 4 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com