Automatic loading and unloading compartment of cable shaft disc of electric power equipment

A power equipment, automatic loading and unloading technology, applied in the direction of vehicles with loading ramps, vehicles with endless chains/loop belts, etc., can solve the problems of increasing cable laying costs, restrictions on the loading and unloading of cable reels, etc., and achieves a simple structure. , The effect of convenient loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

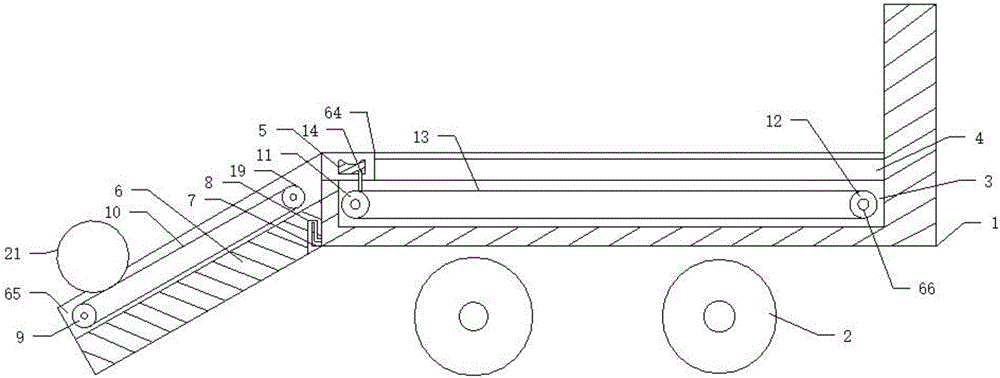

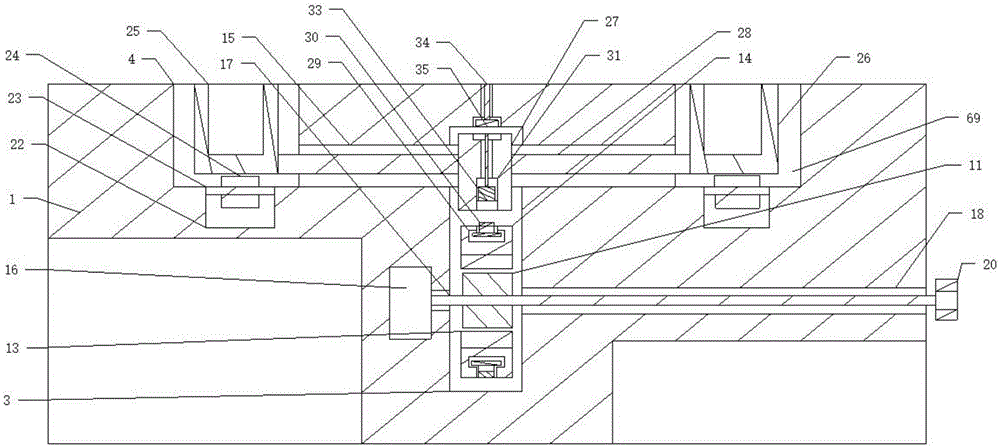

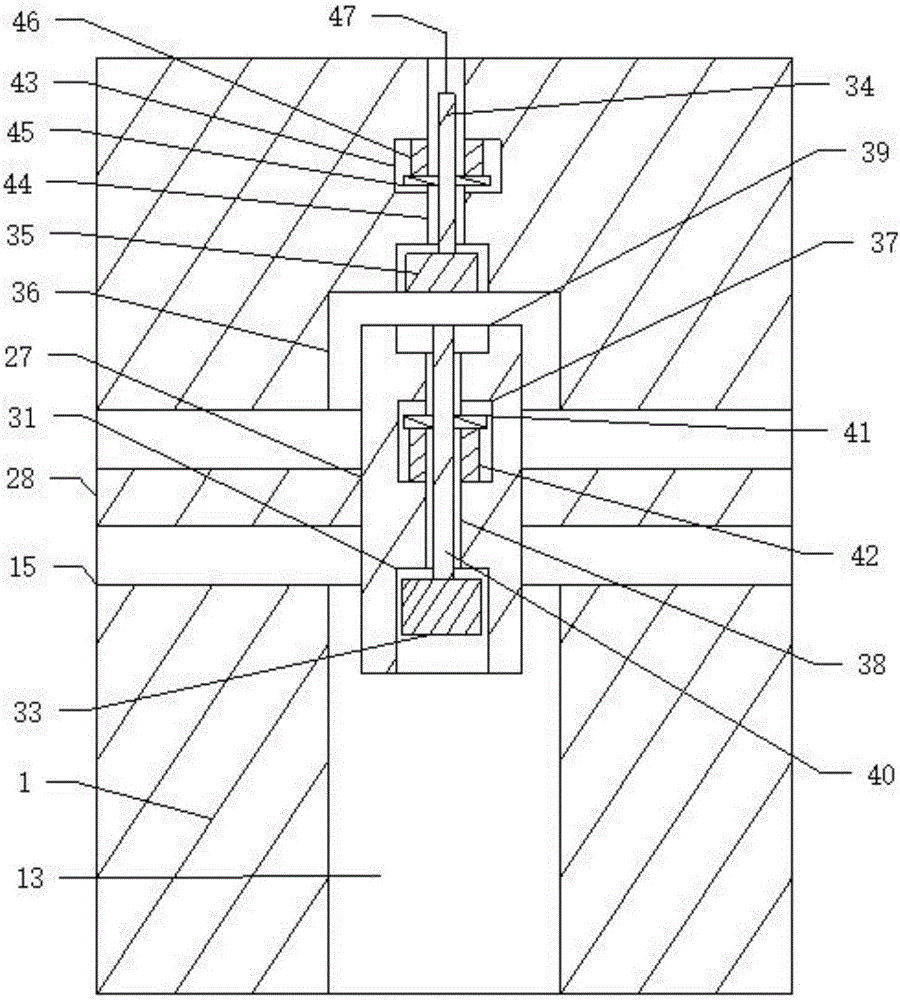

[0033] Such as Figure 1 to Figure 7 As shown, a cable reel automatic loading and unloading compartment for electric equipment includes a cable reel 21 and a compartment floor 1. Rollers 2 are provided on the compartment floor 1, and a seventh recess is provided at the end of the compartment floor 1. Groove 64, two second sliding grooves 4 corresponding to the seventh groove 64 are provided in the compartment floor 1, and a shaft disk sliding positioner 69 is arranged in the seventh groove 4, so that There is also a first chute 3 corresponding to the two second chutes 4 inside the carriage floor 1, and a seventh recess 64 in a concave shape is arranged at the end of the carriage floor 1. The carriage floor 1 is also provided with two parallel second slide grooves 4, the second slide grooves 4 are concavely arranged, and the two second slide grooves 4 are in contact with the seventh groove 64. Correspondingly communicated, a first chute 3 is also provided in the compartment fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com