Battery extracting mechanism of full-automatic AGV battery replacement system

A battery replacement and fully automatic technology, which is applied in vehicle maintenance, power devices, vehicle parts, etc., can solve the problems of time-consuming and labor-intensive batteries, low utilization rate of AGV cars, and long charging time, so as to save labor costs, high practical value, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

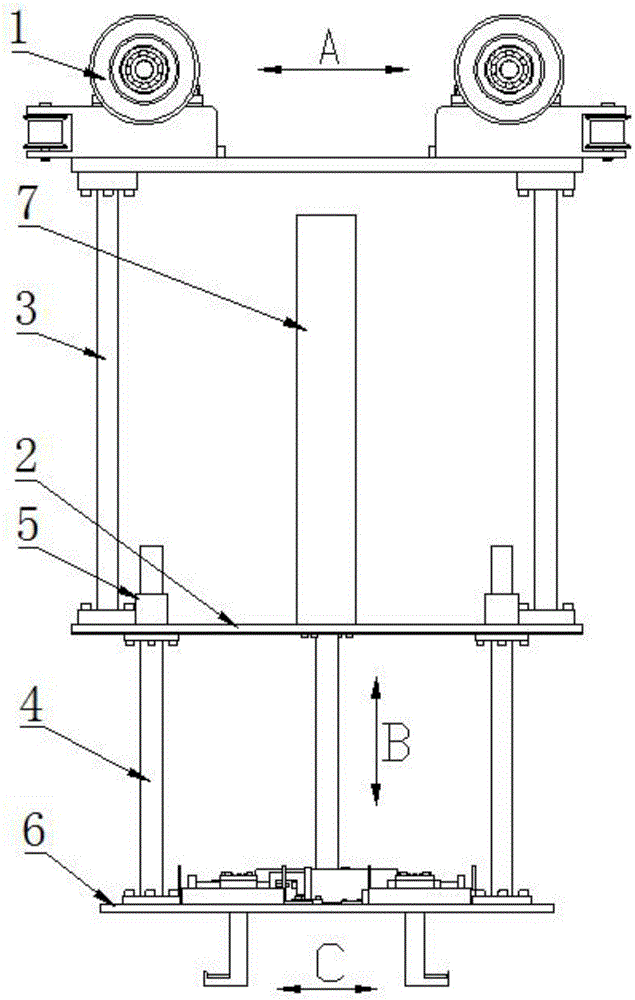

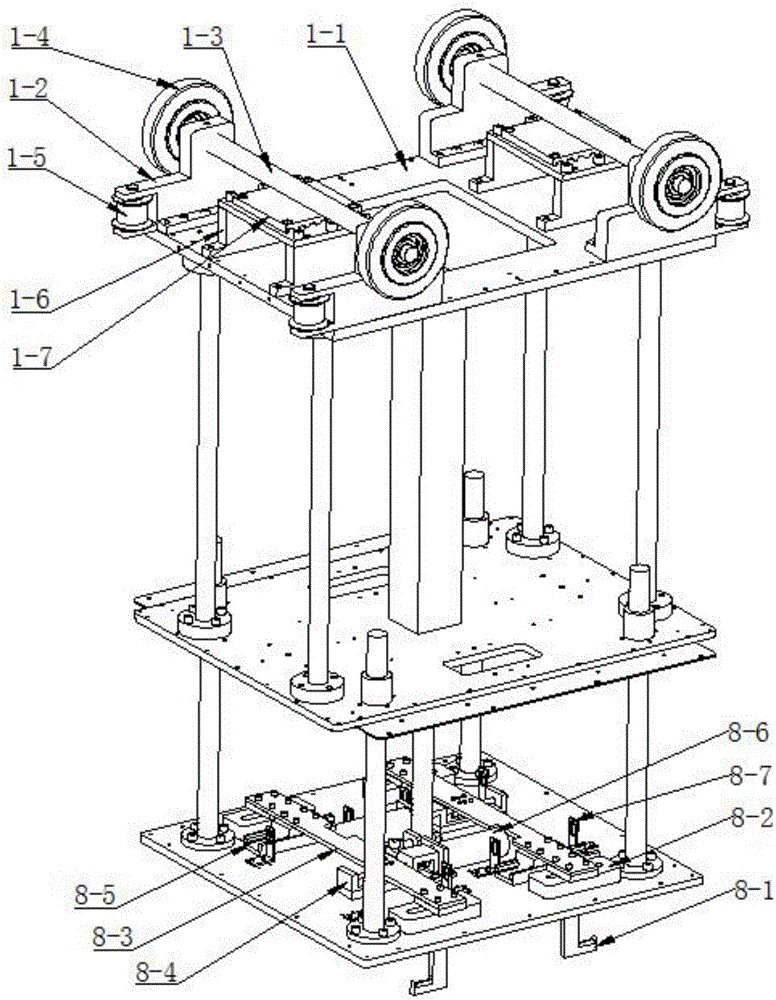

[0022] See figure 1 and figure 2 , the battery extraction mechanism of the fully automatic AGV trolley battery replacement system of this embodiment includes a horizontal rolling device 1, a middle support plate 2, a connecting rod 3, a guide column 4, a linear bearing 5, a lifting plate 6, a lifting drive device 7 and a hook Claw device 8.

[0023] The horizontal rolling device 1 is provided with rollers 1-4. The four corners of the middle supporting plate 2 are respectively fixed on the four corners of the bottom of the horizontal rolling device 1 by four connecting rods 3 . A linear bearing 5 is also respectively fixed on the four corners of the middle supporting plate 2 . There are four guide posts 4, and the upper ends of the four guide posts 4 are slidingly connected with four linear bearings 5 respectively, and the lower ends of the four guide posts 4 are respectively fixed on the four corners of the lifting plate 6. The lifting drive device 7 is installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com