Two-side unloading arc wrapper sheet hopper wagon special for railway

A hopper car and cladding technology, applied in hopper car, railway car body, railway car body parts and other directions, can solve the problems of self-heavy, high ground facilities, large initial investment, etc. The effect of low facility requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

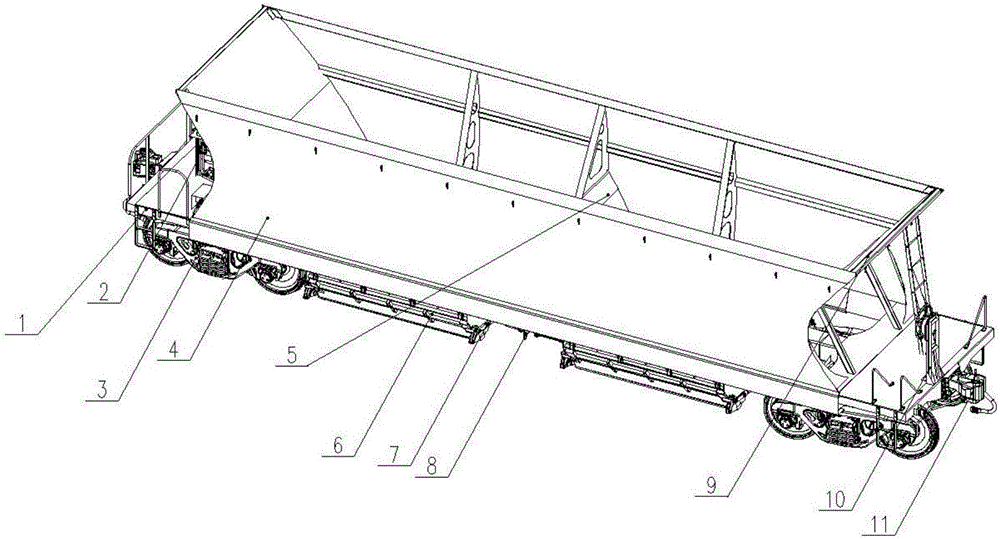

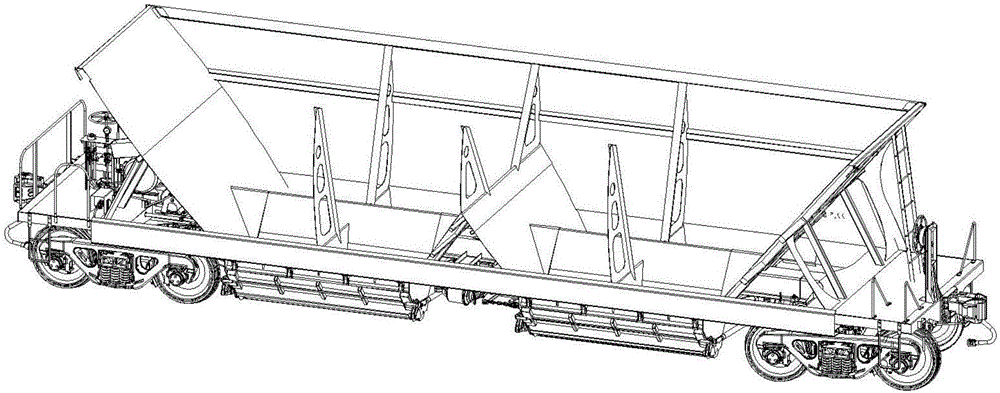

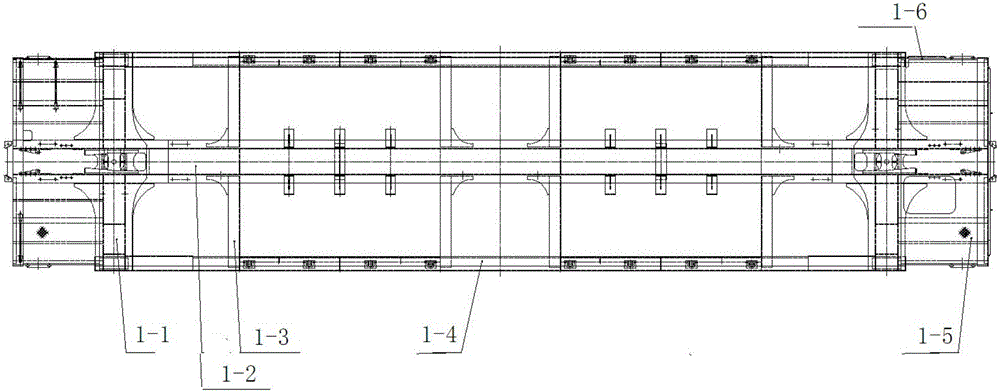

[0041] Such as figure 1 , 2 As shown, the present invention includes an underframe 1, two bogies 3, two coupler buffer devices 10, a wind brake device 8, a hand brake device 9, two side walls 4, and two end walls 9. One funnel 5, four bottom doors 6, one pneumatic pipeline device 2, and one bottom door opening and closing mechanism 7.

[0042] A bogie 3 is installed at both ends of the underframe 1, and a hook buffer device 10 is installed on each of the two bogies. The bottom of the underframe 1 and the bogie 3 are equipped with wind and hand brakes. Devices 8 and 9 are used for braking and parking of vehicles; two side walls 4 and two end walls 9 arranged symmetrically with respect to the central axis of the underframe are arranged on the upper part of the underframe 1; the underframe 1 and two The side wall 4 and the two end walls 9 surround ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com