Universal wheel braking device and dual-wheel synchronous brake system using braking device

A technology of brake device and universal wheel, which is applied in the direction of children's carriage/baby carriage, children's carriage/cradle car accessories, motor vehicles, etc. cost, extended service life, and the effect of solving the problem of rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

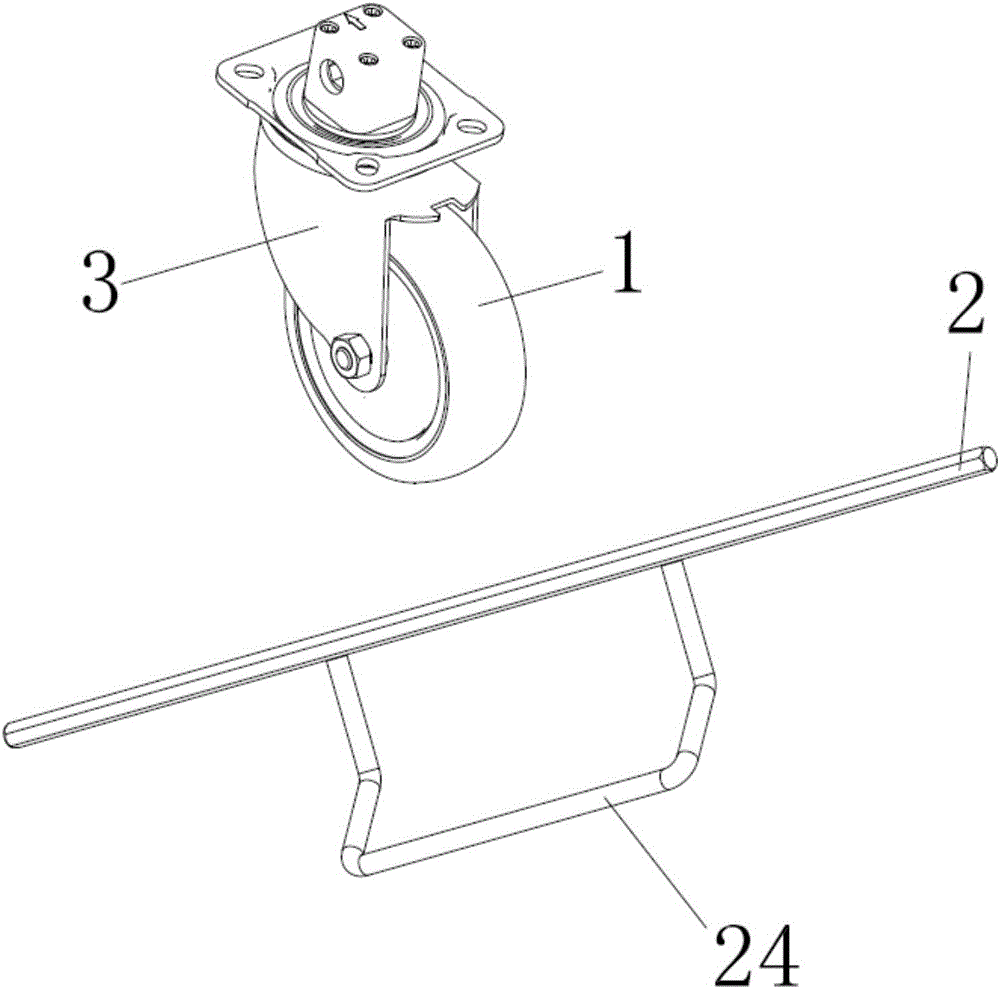

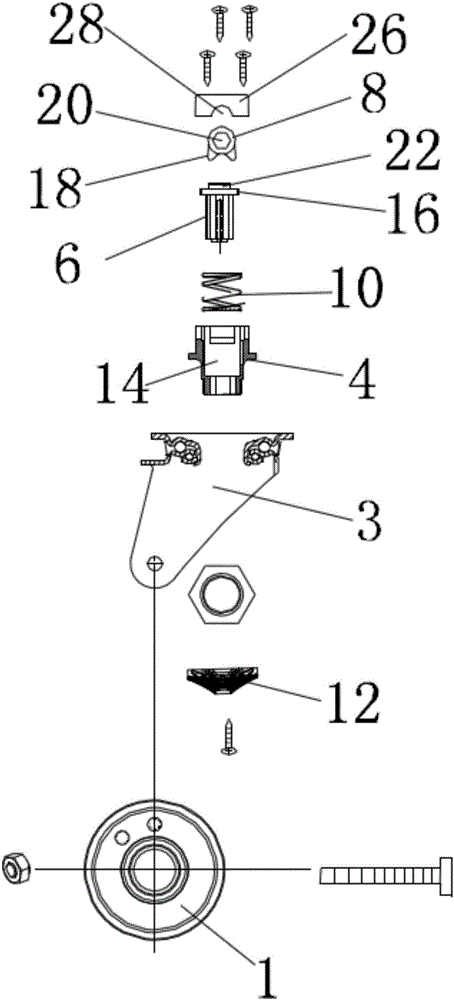

[0034] Such as figure 1 , 2 As shown, a universal wheel brake device is disclosed in this embodiment. The universal wheel 1 is installed on the wheel frame 3 through a screw and a nut, and the top plate of the wheel frame 3 is provided with a mounting hole. The above universal wheel brake The device includes a rotary press brake assembly and a brake lever 2, the above rotary press brake assembly includes a base 4, a brake shaft 6, a rotary brake button 8, a brake spring 10 and a brake contact 12,

[0035] The above-mentioned base 4 is a columnar structure as a whole, part of which passes through the installation hole, and is fixed on the wheel frame 3 by nuts. The above-mentioned base 4 is provided with a central axis hole 14, and the central axis hole 14 penetrates the base 4 axially;

[0036] The above-mentioned brake shaft 6 is arranged in the central shaft hole 14, and can move up and down in the central shaft hole 14, and its outer wall is provided with a convex ring 16;...

Embodiment 2

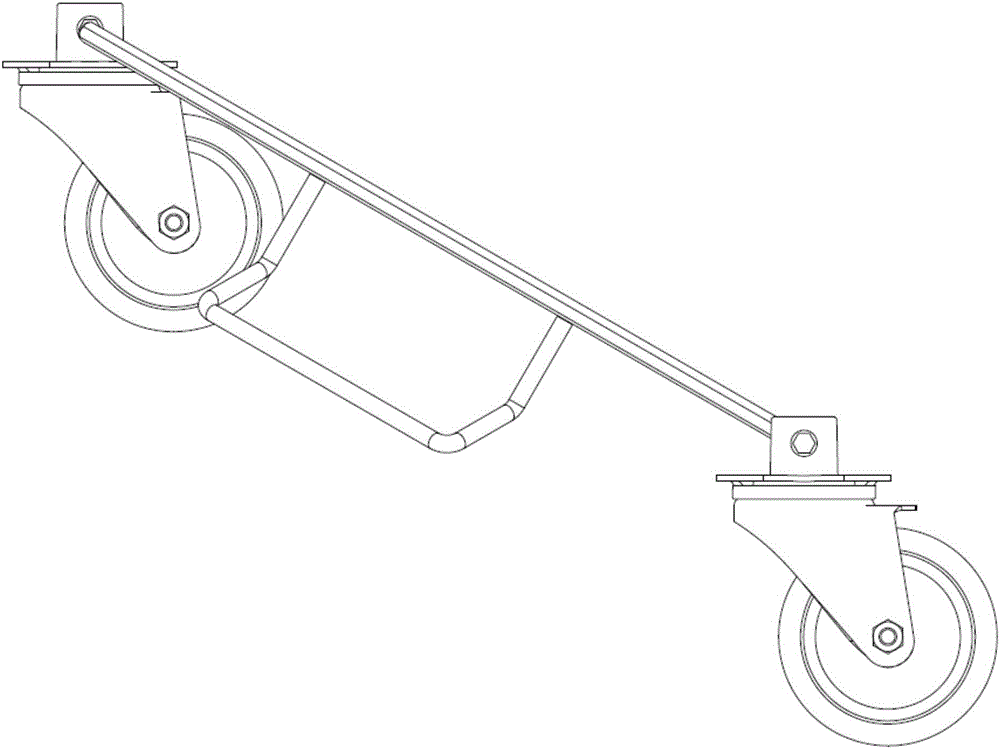

[0050] Such as image 3 As shown, this implementation provides a dual-wheel synchronous braking system, including a brake lever 2 and two rotary push brake assemblies as in the first embodiment above, and the two rotary push brake assemblies mentioned above are all connected through their respective rotary brake buttons. 8 is connected to the brake lever 2, and the brake pedal 24 is arranged on the brake lever 2 between the two above-mentioned rotating and pressing brake assemblies.

[0051] The brake system with the above structure can realize one-lever synchronous double brakes, the operation is very convenient and simple, and at the same time, the problem of vehicle slipping in the prior art can be solved.

[0052] Certainly, according to actual use needs, also can design one bar synchronous multi-braking, one brake bar 2 controls the synchronous braking of three casters, four casters or even more casters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com