A hexapod robot based on parallel mechanism and its working method

A technology of hexapod robot and working method, which is applied in the fields of motor vehicles, transportation and packaging, etc., can solve the problems of unrealized adaptation to complex terrain, weak adaptability to complex terrain, limited movement flexibility, etc., and achieve high rigidity and movement The effect of small load and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

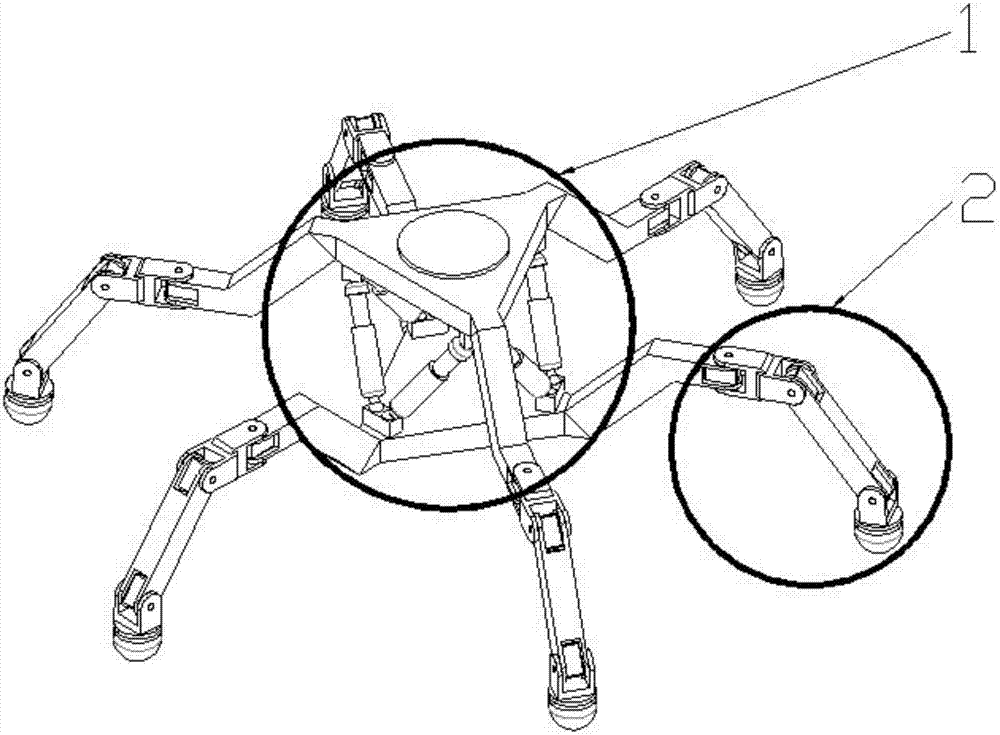

[0044] like Figure 1 to Figure 3 As shown, this embodiment provides a hexapod robot based on a parallel mechanism, which mainly includes two parts: a main body 1 and a mechanical leg 2:

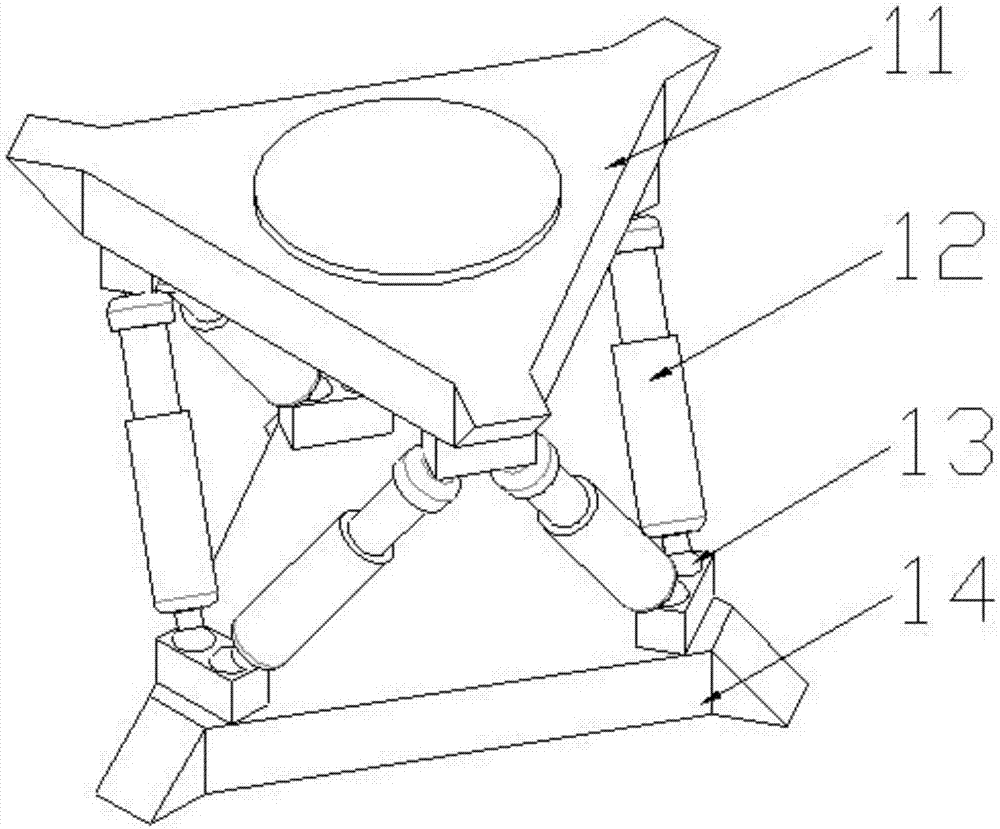

[0045]Wherein the main body 1 includes an upper platform 11, a lower platform 14 and six servo electric cylinders 12, the upper platform 11 and the lower platform 14 are equilateral triangular plate structures, and the upper platform 11 and the lower platform 14 are arranged in a 60° dislocation (that is, the upper platform surrounds it After the center rotates 60 ° and overlaps with the lower platform), the top corners of the upper platform 11 and the lower platform 14 are provided with hinge points, and each hinge point is connected to two of them by a spherical hinge 13. Servo electric cylinders 12 (such as figure 2 shown);

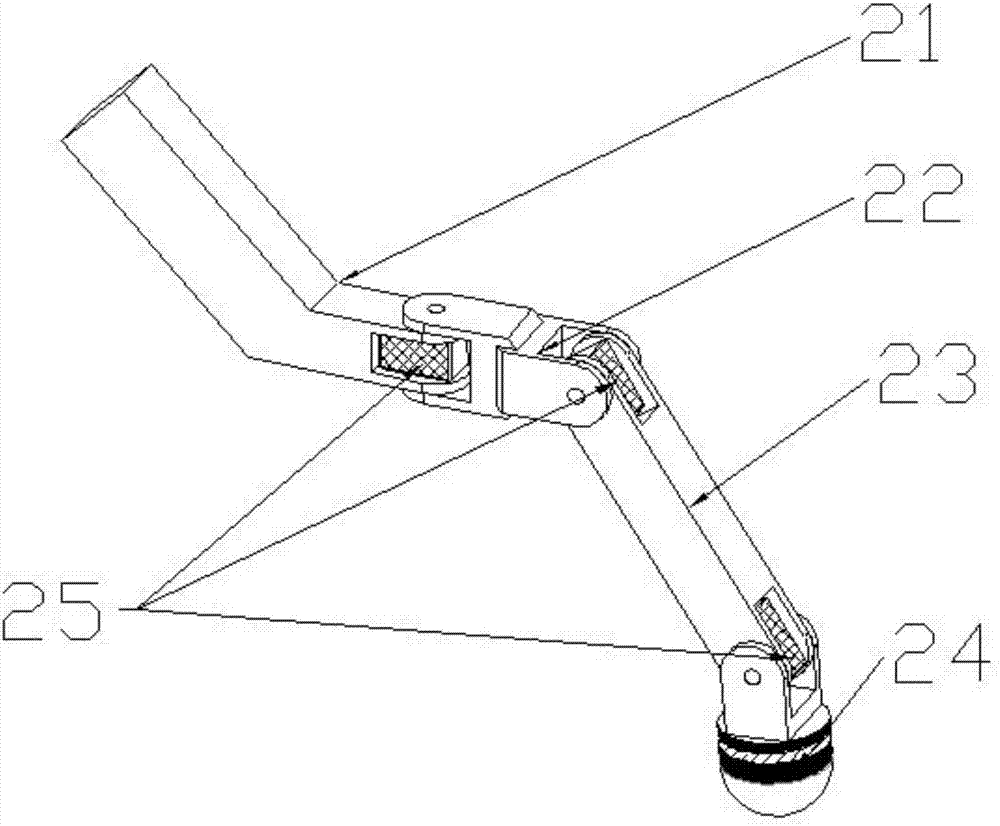

[0046] The mechanical leg 2 includes a first connecting rod 21, a second connecting rod 22, a third connecting rod 23 and a force sensor 24. The joint of the first...

Embodiment 2

[0051] A hexapod robot based on a parallel mechanism, the structure of which is as described in Embodiment 1, the difference is that in this embodiment, the servo electric cylinder is replaced by a hydraulic cylinder, and the first connecting rod 21 in the mechanical leg 2 is connected to the upper platform 11. The lower platform 14 is connected by pin shafts.

Embodiment 3

[0053] A hexapod robot based on a parallel mechanism, the structure is as described in Embodiment 1, the difference is that: the bottom of the lower platform 14 is provided with a rotary support mechanism 3, and the rotary support mechanism 3 includes a motor 32, a gear 31, and a gear shaft 35 , oil cylinder 33, support frame 34 and a fixed platform, motor 32 is installed on the fixed platform, the output shaft of motor 32 is connected with gear 31 transmission, and gear 31 meshes with gear shaft 35, and gear shaft 35 one ends are fixedly connected with lower platform 14 ( When the gear shaft rotates, the lower platform is driven to also rotate), the other end is connected to the cylinder barrel of the oil cylinder 33 by the bearing on the fixed platform (the gear shaft rotates, but the oil cylinder does not rotate thereupon), and the piston rod of the oil cylinder 33 is connected with the support frame 34 . When the hexapod robot needs to turn quickly, the quick turn of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com