Plane with nose-up pitching moment

A nose-up moment, aircraft technology, applied in the field of aviation aircraft, can solve problems such as weak climbing ability, slow take-off of aircraft, poor anti-interference ability, etc., to achieve the effect of enhancing anti-interference ability, good maneuverability and stability, and ensuring normal flight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

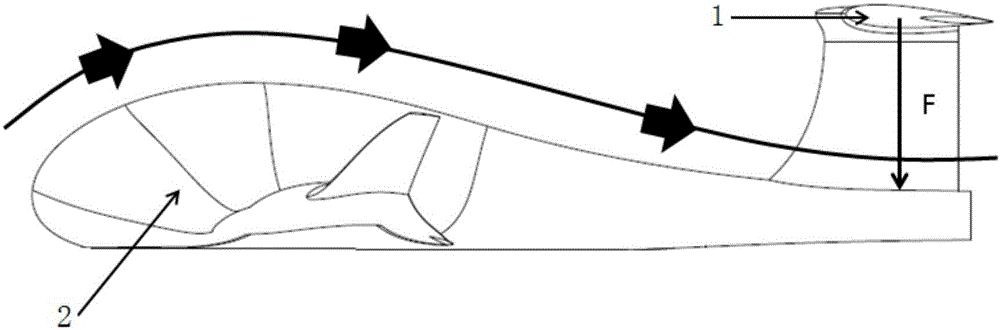

[0025] Such as figure 1 Shown, a kind of aircraft of head-up moment comprises fuselage 2 and empennage, and described empennage comprises vertical empennage and horizontal empennage 1, and vertical empennage is installed on the rear portion of described fuselage 2, and horizontal empennage 1 is installed on the top of vertical empennage , forming a T-shaped tail, a raised portion is set on the top surface of the front of the fuselage 2, and the smooth transition between the raised portion and the rear of the fuselage 2 makes the top surface of the fuselage 2 form a streamlined surface.

[0026] The horizontal stabilizer 1 is a symmetrical airfoil, and the lowest point of the top surface of the fuselage 2 is located at the tail end of the fuselage 2 . The lowest point of the top surface of the fuselage 2 is located at the rear end of the fuselage 2, so that the flow of the air on the surface of the aircraft is laminar, avoiding turbulent flow, the aircraft suffers the least res...

Embodiment 2

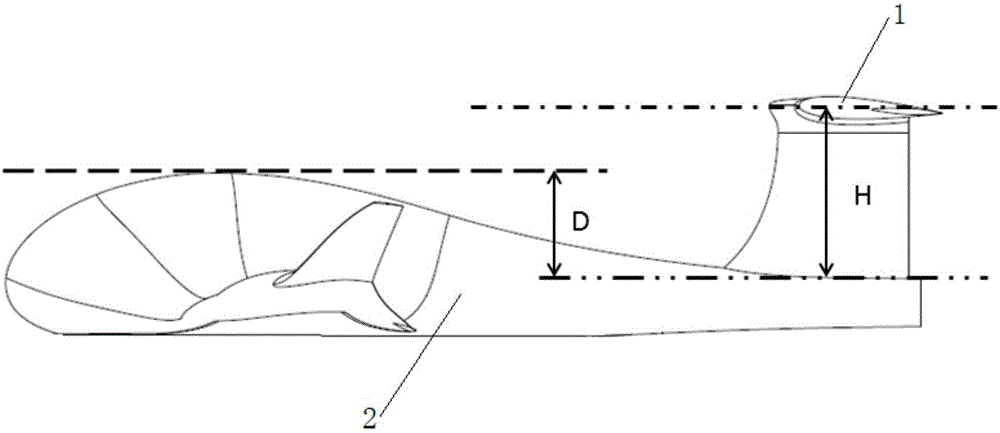

[0032] The features identical to those of the first embodiment will not be described in detail. The different features of the first embodiment are: the height difference between the highest point and the lowest point of the top surface of the fuselage 2 is D, and the upper surface of the horizontal stabilizer 1 is The height difference from the lowest point on the top surface of the fuselage 2 is H, and D=1.0H.

Embodiment 3

[0034] The features identical to those of the first embodiment will not be described in detail. The different features of the first embodiment are: the height difference between the highest point and the lowest point of the top surface of the fuselage 2 is D, and the upper surface of the horizontal stabilizer 1 is The height difference from the lowest point on the top surface of the fuselage 2 is H, and D=1.3H.

[0035] In the present invention, the relationship between the height difference D between the highest point and the lowest point of the fuselage 2 top surface and the height difference H between the horizontal stabilizer 1 upper surface and the lowest point of the fuselage 2 top surface is not limited to the embodiment Among the several values mentioned above, D can also take other values greater than 0.3H and less than 2H.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com