Helicopter pod loading and unloading operation platform

A technology for operating platforms and helicopters, which is applied in hoisting devices, aircraft assembly, aircraft parts, etc., and can solve problems such as labor-intensive, unstable installation quality, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

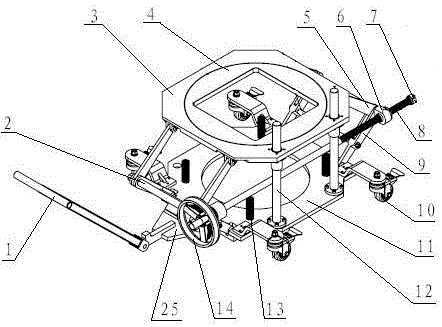

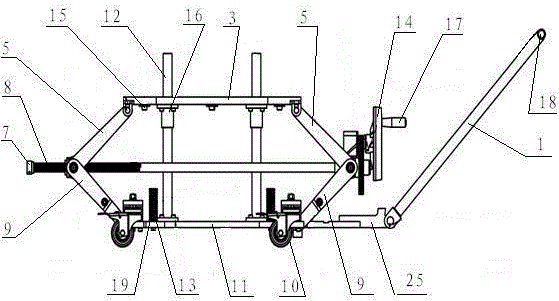

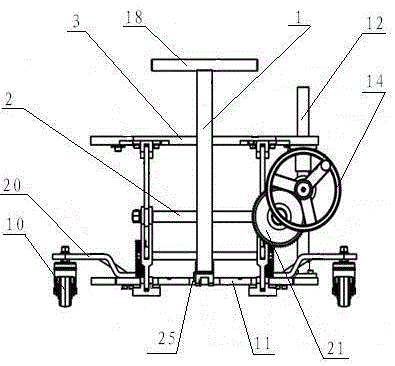

[0021] A loading and unloading operation platform for a helicopter photoelectric pod, the platform (3) is rotatably connected with a turntable (4) through bearings or balls, a liftable supporting device is provided between the platform and the bottom plate (11), and a removable unit. The structure of the liftable supporting device is as follows: two lower connecting rods (9) are rotatably connected to the left and right sides of the bottom plate, and the upper ends of the lower connecting rods are rotatably connected to the cross bar (2). The upper end is rotatably connected to the lower end of the upper link (5), and the upper end of the upper link is rotatably connected to the platen (3). The platen is provided with a guide rod sleeve (16), and the guide rod (12) is connected with clearance In the hole of the guide rod cover, the lower part of the guide rod is fixedly connected to the bottom plate; the rear end of the left cross bar is fixedly connected with a screw nut (6),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com