Baking workshop filler fine powder pool

A filler and fine powder technology, which is applied in the field of storage tanks, can solve the problems of waste of filler fine powder and pollution of the surrounding environment, and achieve the effects of recycling, preventing pollution of the surrounding environment, and preventing waste of filler fine powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

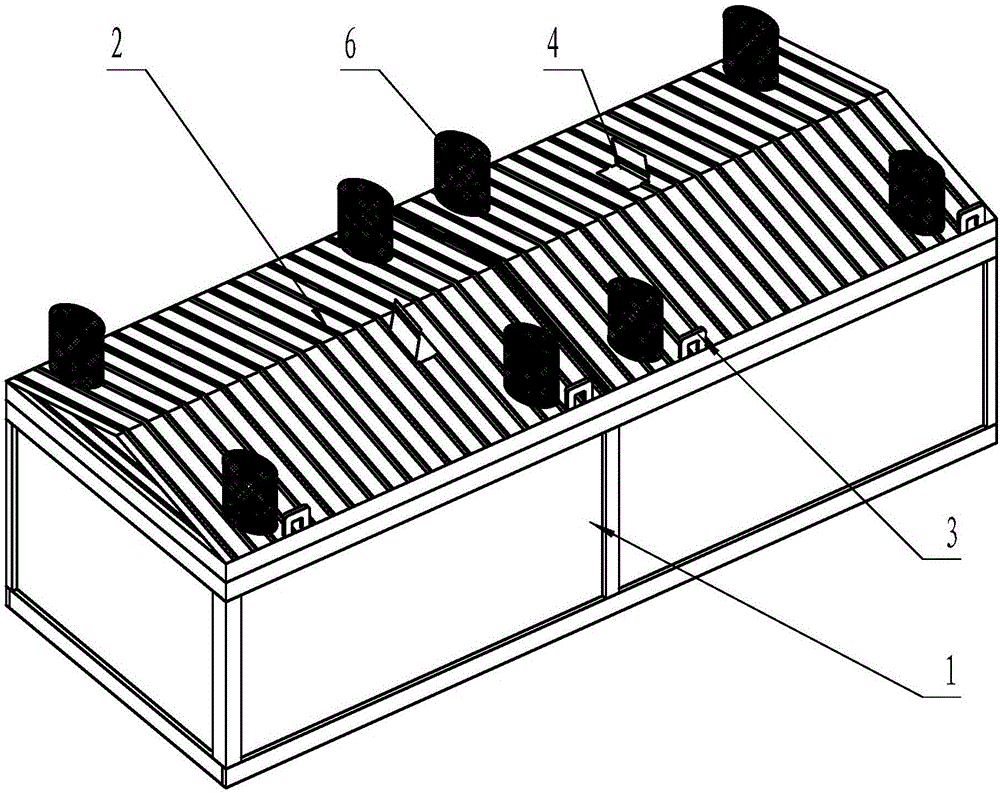

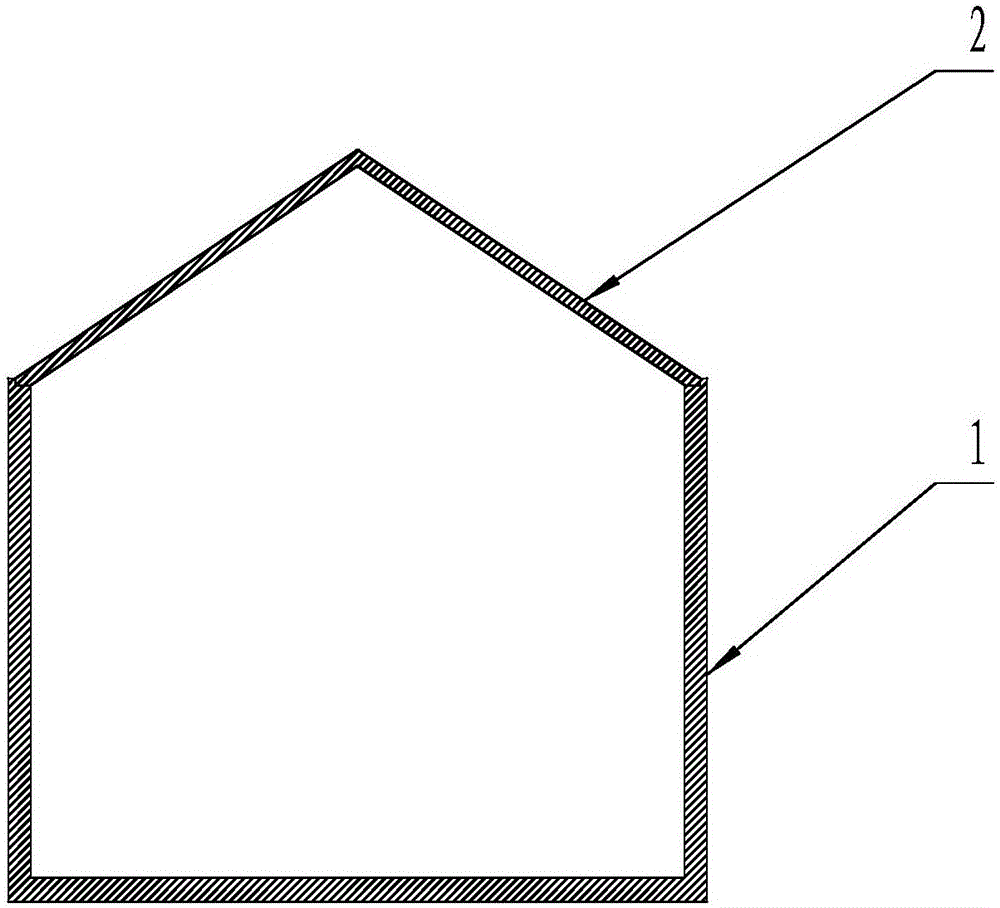

[0015] Such as figure 1 , figure 2 , image 3 As shown, a filling material fine powder pool in a roasting workshop includes a pool body 1 and a pool cover 2, and the pool cover 2 is provided with a pool cover lifting nose 3 and a filling material fine powder discharge port 4, which is characterized in that: The top periphery of the pool body 1 has an upward vertical protruding part, and when the pool cover 2 is fastened to the top of the pool body 1, the upward vertical protruding part on the top periphery of the pool body 2 can enclose the pool cover 2 buckle The part that is connected to the top of the pool body 1, the pool cover 2 can be in close contact with the top of the pool body 1 and the upward vertical protruding part on the periphery of the top of the pool body 1;

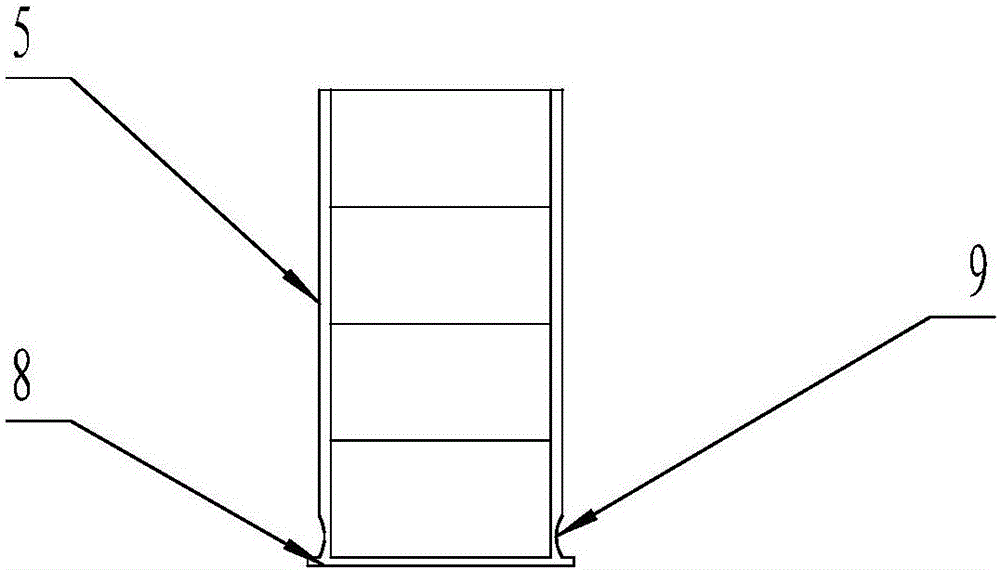

[0016] The pool cover 2 is also provided with 8 air release devices in sequence, the air release device includes an annular bracket 5 and a dust collection bag 6, the bottom of the annular bracket 5 h...

Embodiment 2

[0018] Such as figure 1 , figure 2 , image 3 As shown, a filling material fine powder pool in a roasting workshop includes a pool body 1 and a pool cover 2, and the pool cover 2 is provided with a pool cover lifting nose 3 and a filling material fine powder discharge port 4, which is characterized in that: The top periphery of the pool body 1 has an upward vertical protruding part, and when the pool cover 2 is fastened to the top of the pool body 1, the upward vertical protruding part on the top periphery of the pool body 2 can enclose the pool cover 2 buckle The part that is connected to the top of the pool body 1, the pool cover 2 can be in close contact with the top of the pool body 1 and the upward vertical protruding part on the periphery of the top of the pool body 1;

[0019] The pool cover 2 is also provided with 8 air release devices in sequence, the air release device includes an annular bracket 5 and a dust collection bag 6, the bottom of the annular bracket 5 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com