Damping device of self-propelling car conveyor

A shock-absorbing device and self-propelled trolley technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve problems such as object shaking, easy shaking, unsafety, etc., and achieve adjustable pre-pressure and good shock absorption effect , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

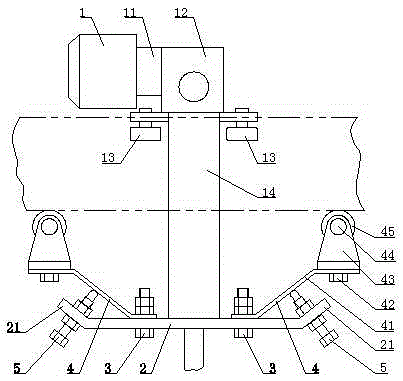

[0007] see figure 1 , the present invention includes a trolley 1, the trolley 1 includes a motor 11, a reducer 12, a guide wheel 13 and a car body 14, and also includes a load plate 2, several connecting bolts 3, two round head adjusting screws 5 and two symmetrical The damping devices 4 located on the left and right sides of the bearing plate 2, each of the damping devices 4 includes a leaf spring 41, a bearing bolt 42, a roller support 43, a rotating shaft 44 and a roller 45, and the left and right sides of the bearing plate 2 Two flanging plates 21 are symmetrically arranged, and the bearing plate 2 is welded on the lower end of the vehicle body 14, and the damping device 4 is mounted on the bearing plate 2 through connecting bolts 3, and the two round head adjusting screws 5 are respectively arranged on the two flanged plates 21 of the bearing plate 2, the leaf spring 41 is connected with the roller support 43 through the support bolt 42, and the roller support 43 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com