A lotion pump automatic assembly machine

An automation group and emulsion pump technology, applied in the direction of assembly machines, conveyor objects, transportation and packaging, etc., can solve the problems of low efficiency of assembly machines, achieve the effect of improving assembly efficiency and shortening the assembly period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

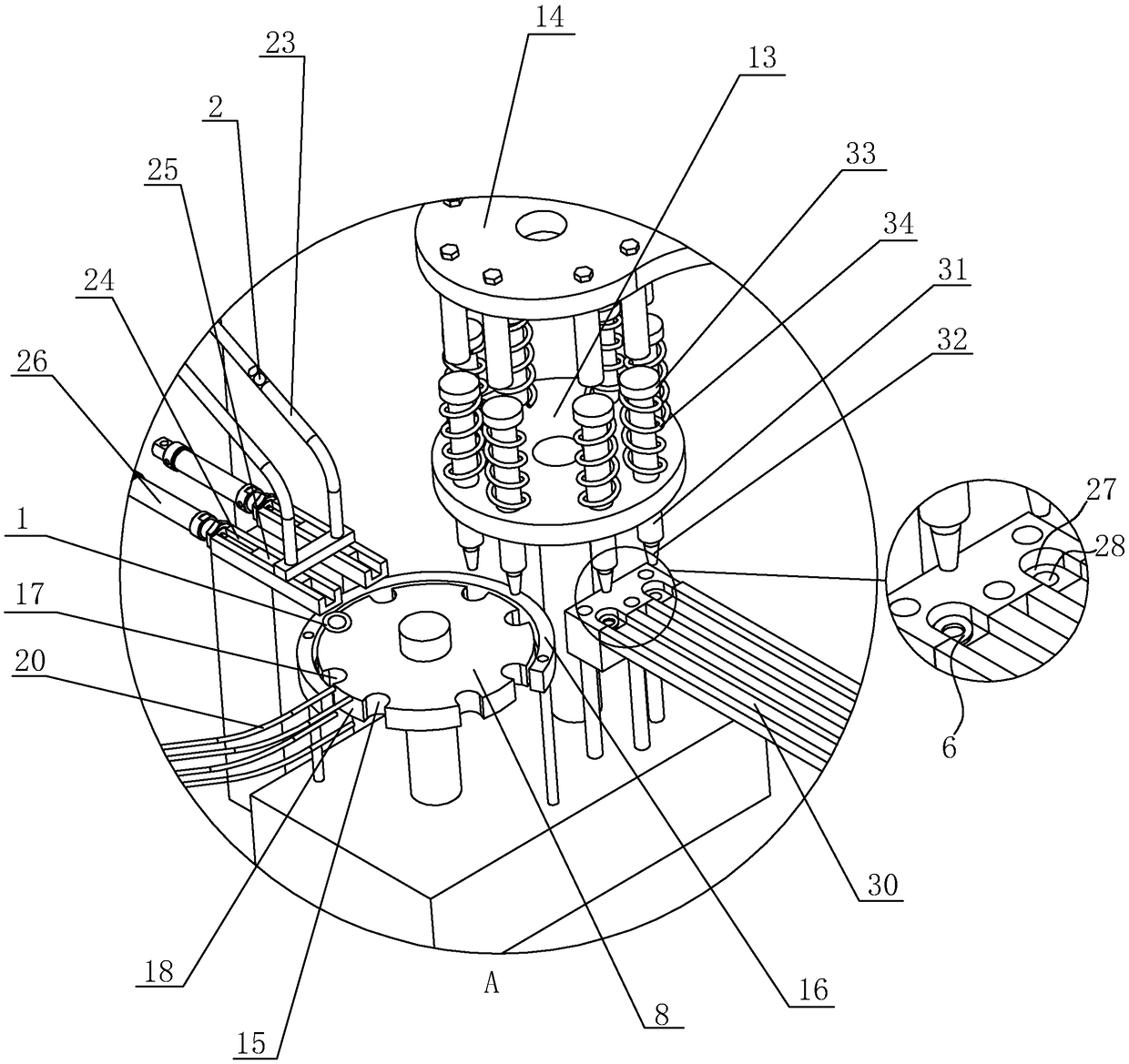

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings.

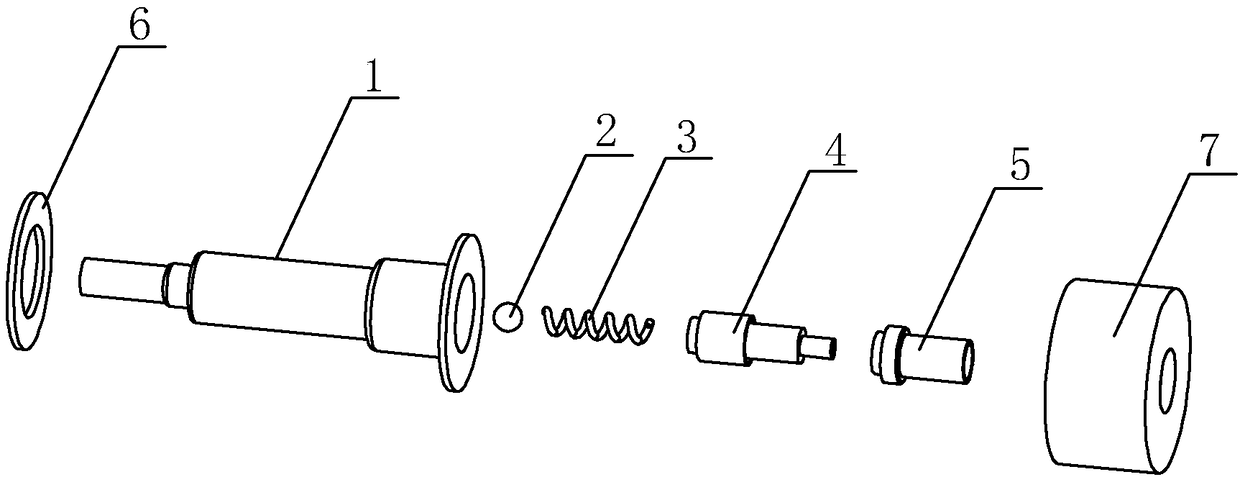

[0045] The embodiment discloses an automatic lotion pump assembly machine, which is used to assemble the semi-finished lotion pump (excluding the top pressing part); the semi-finished product is hereinafter referred to as the headless pump, such as figure 1 As shown, the headless pump part mainly includes pump body 1, gasket 6, glass bead 2, spring 3, piston tube 4, fixing sleeve 5, screw cover 7; glass bead 2, spring 3, piston tube 4, fixing sleeve 5 in order Installed into the pump body 1, the gasket 6 is sleeved on the pump body 1 and attached to the lower side of the upper flange of the pump body 1, and the screw cover 7 is clamped on the flange.

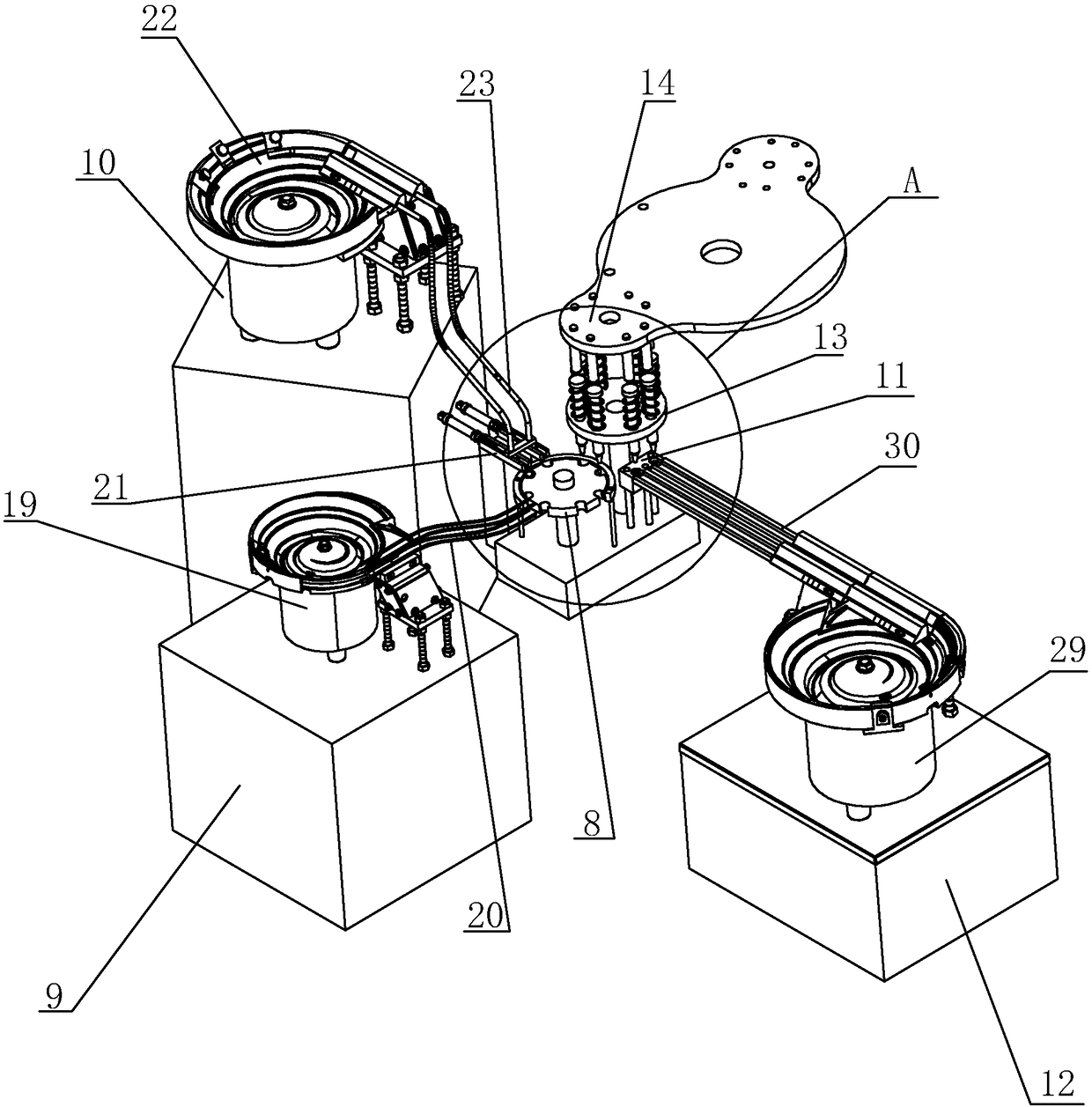

[0046] This embodiment mainly includes a main assembly mechanism, a first secondary assembly mechanism, and a second secondary assembly mechanism.

[0047] The first auxiliary assembly mechanism is used to com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com