Patents

Literature

30results about How to "Shorten the assembly period" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

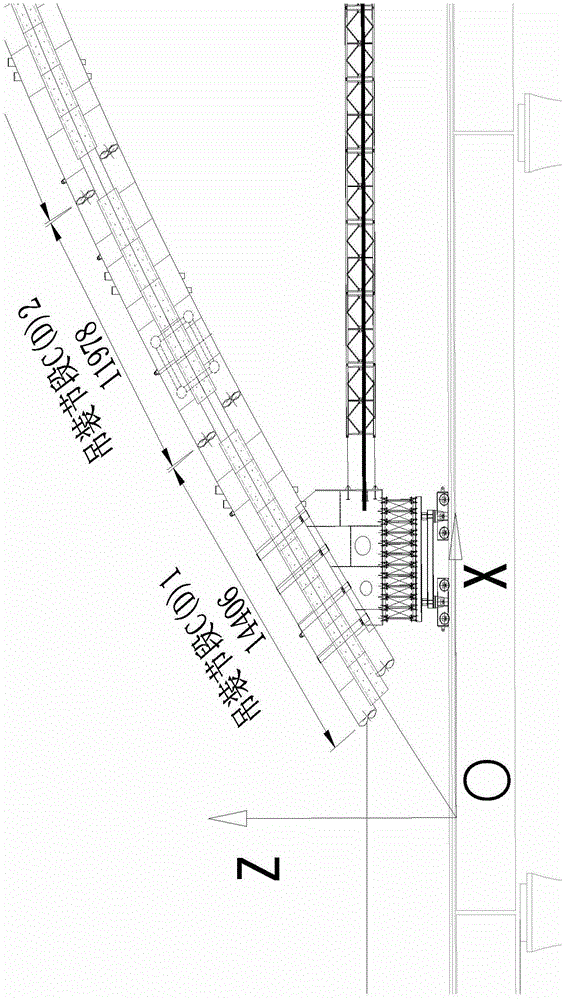

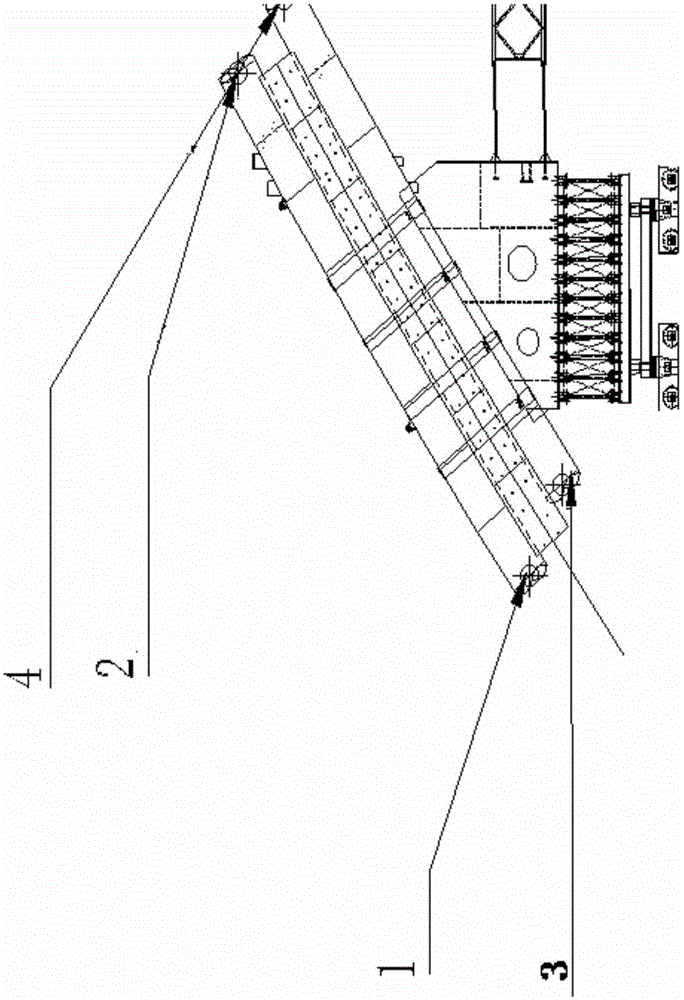

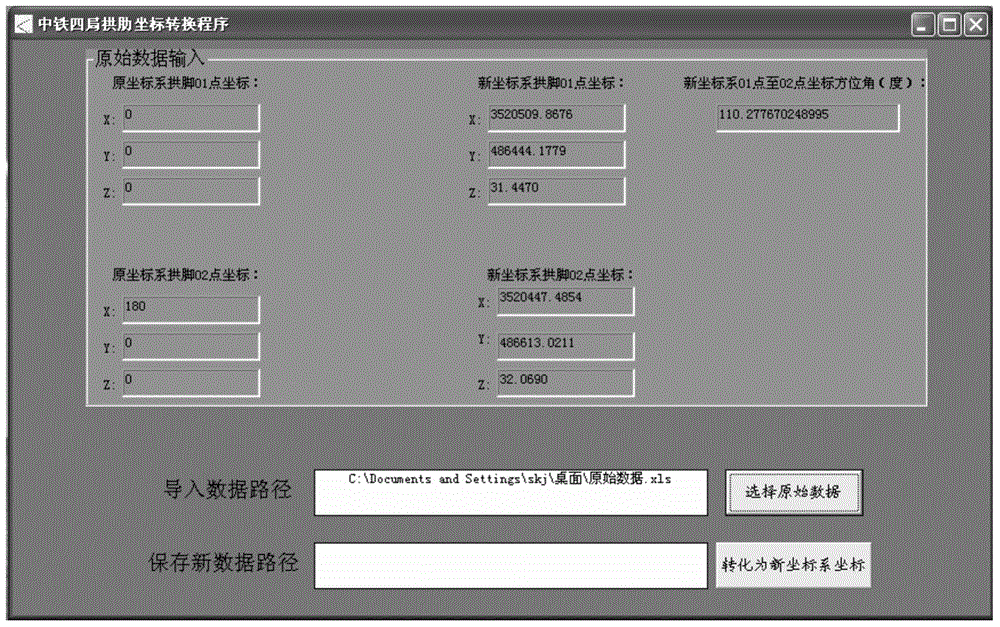

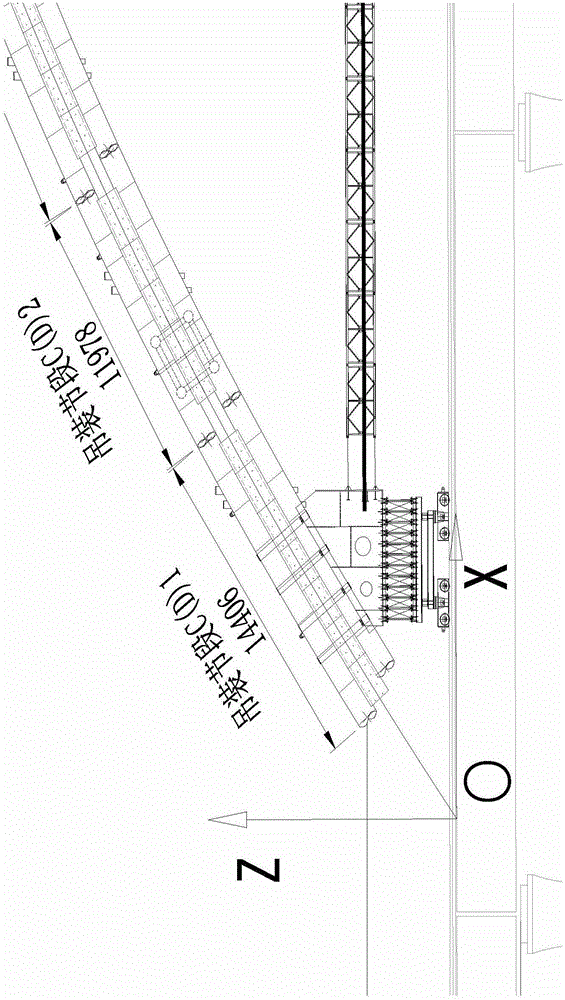

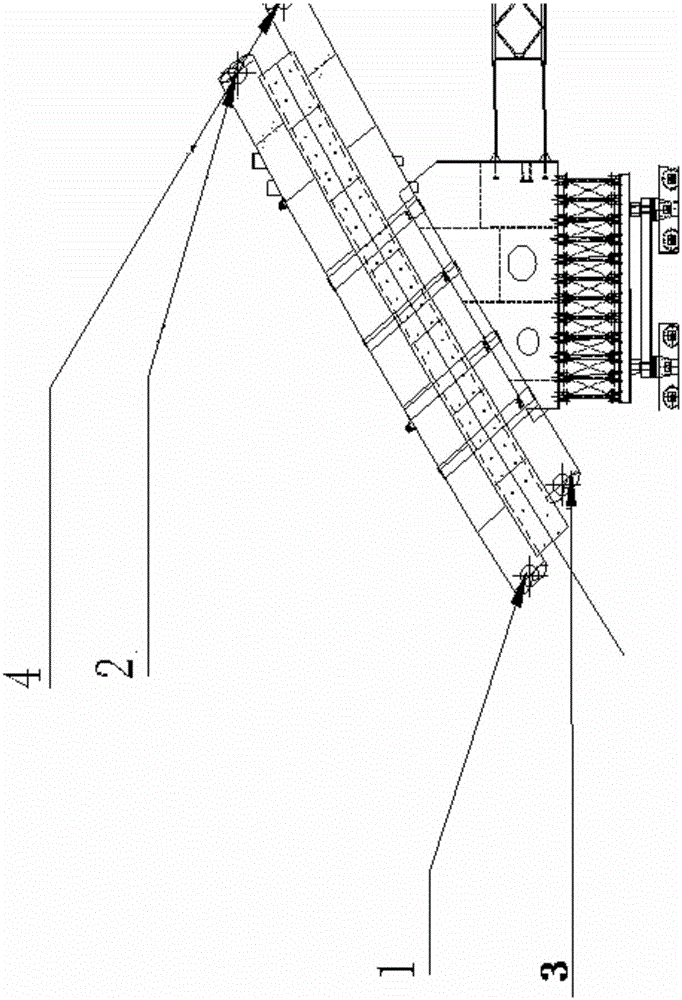

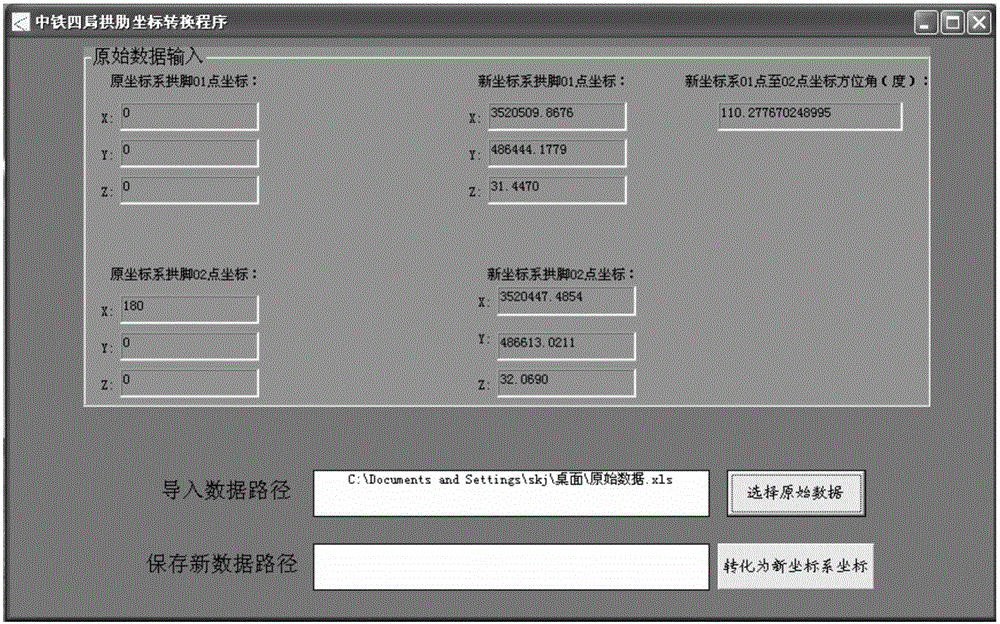

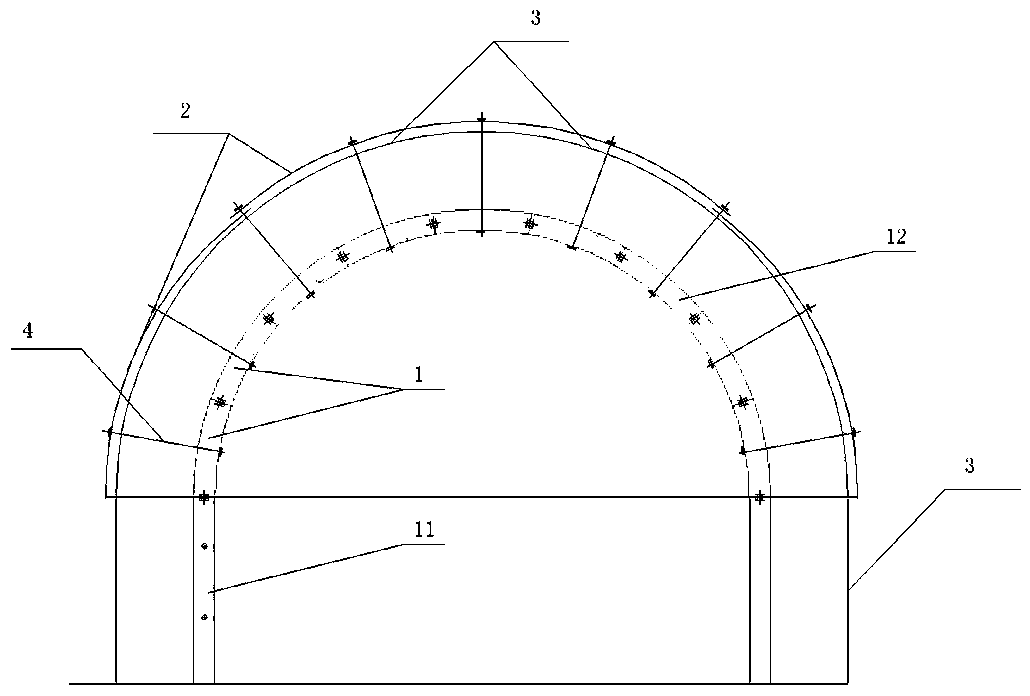

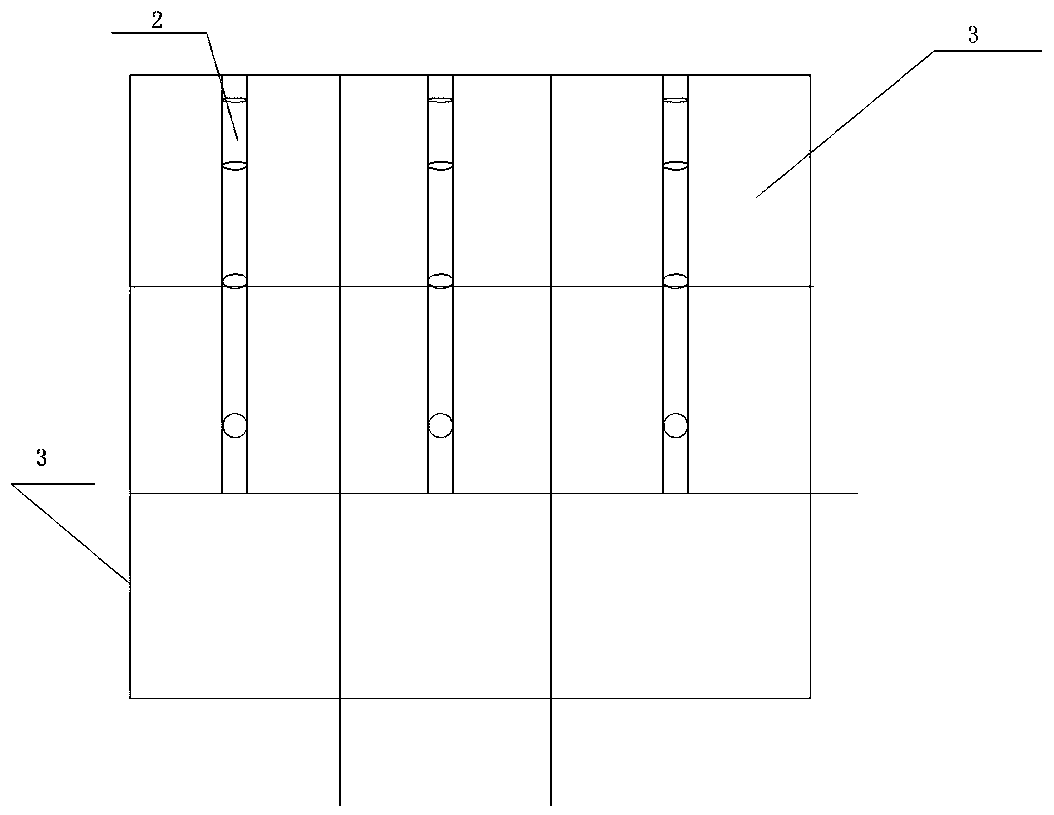

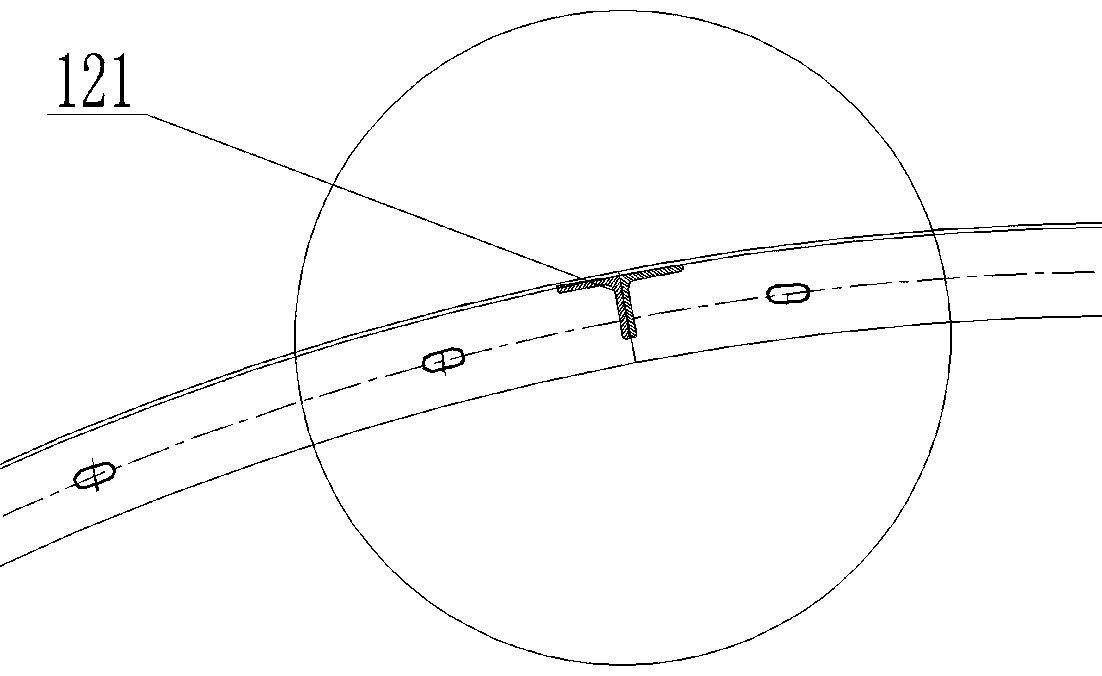

Intelligent measurement construction method for positioning arch rib of long railway tunnel

ActiveCN103821088AAchieve conversionAchieve connectionBridge erection/assemblyRailway tunnelMeasurement point

The invention provides an intelligent measurement construction method for positioning arch ribs of a long railway tunnel. During arch rib positioning, the intelligent measurement construction method includes: (1) determining a coordinate conversion parameter, (2) determining a coordinate conversion formula, (3) editing a software source code and an instrument interface source code, (4) testing software and applying if the software is qualified, (5) pasting light-reflecting pieces at four corners designed for the arch rib to serve as positioning measurement points for the arch rib, (6) performing assembling measurement for the first section of the arch rib, and (7) performing intelligent positioning measurement for the next section of the arch rib till all positioning assembling of the arch ribs are finished. The intelligent measurement construction method is applied to 180 meters of continuous beam arch rib assembling in the Nanfei river bridge of the HeFu railway, safety risk during constructional measurement is reduced, arch rib positioning efficiency is improved greatly, and cost is saved.

Owner:THE FOURTH ENG CO LTD OF CTCE GRP

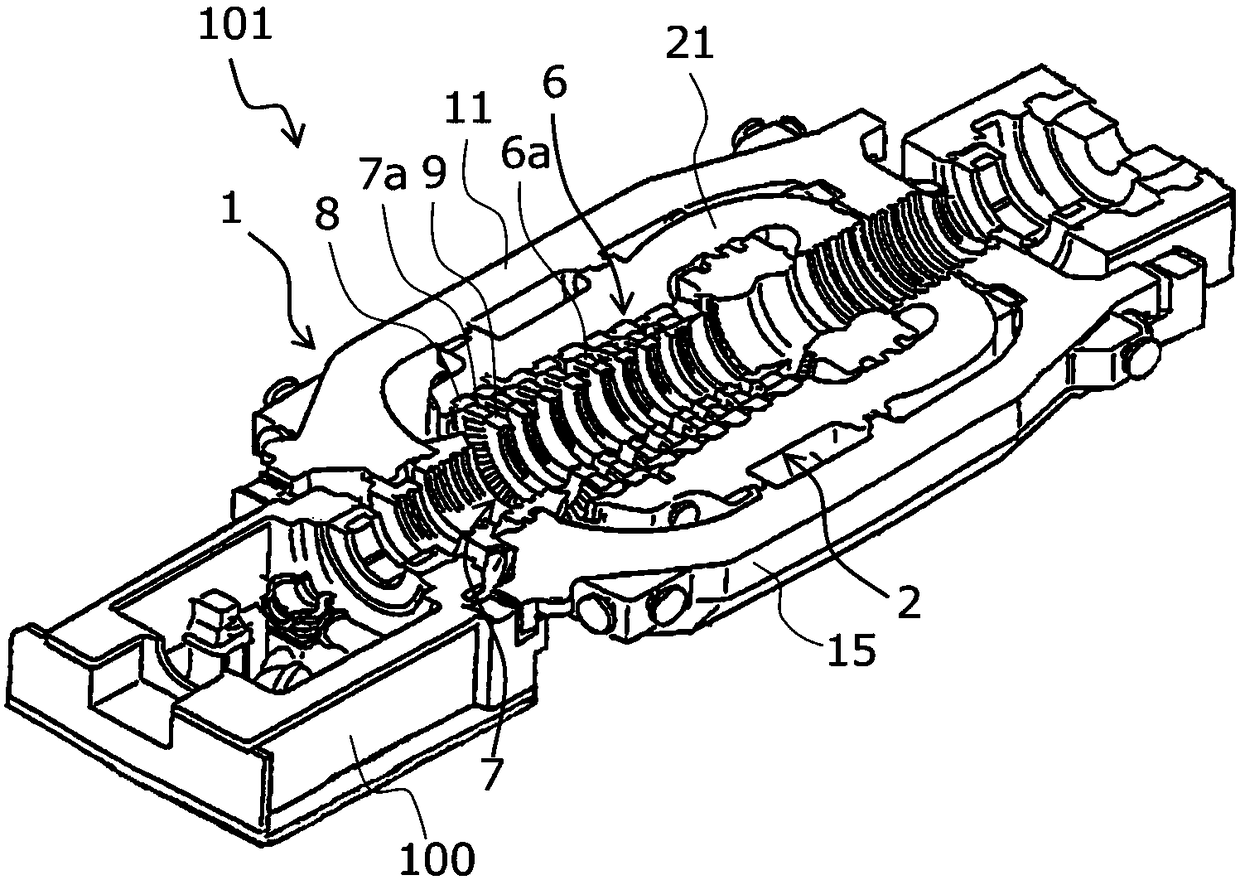

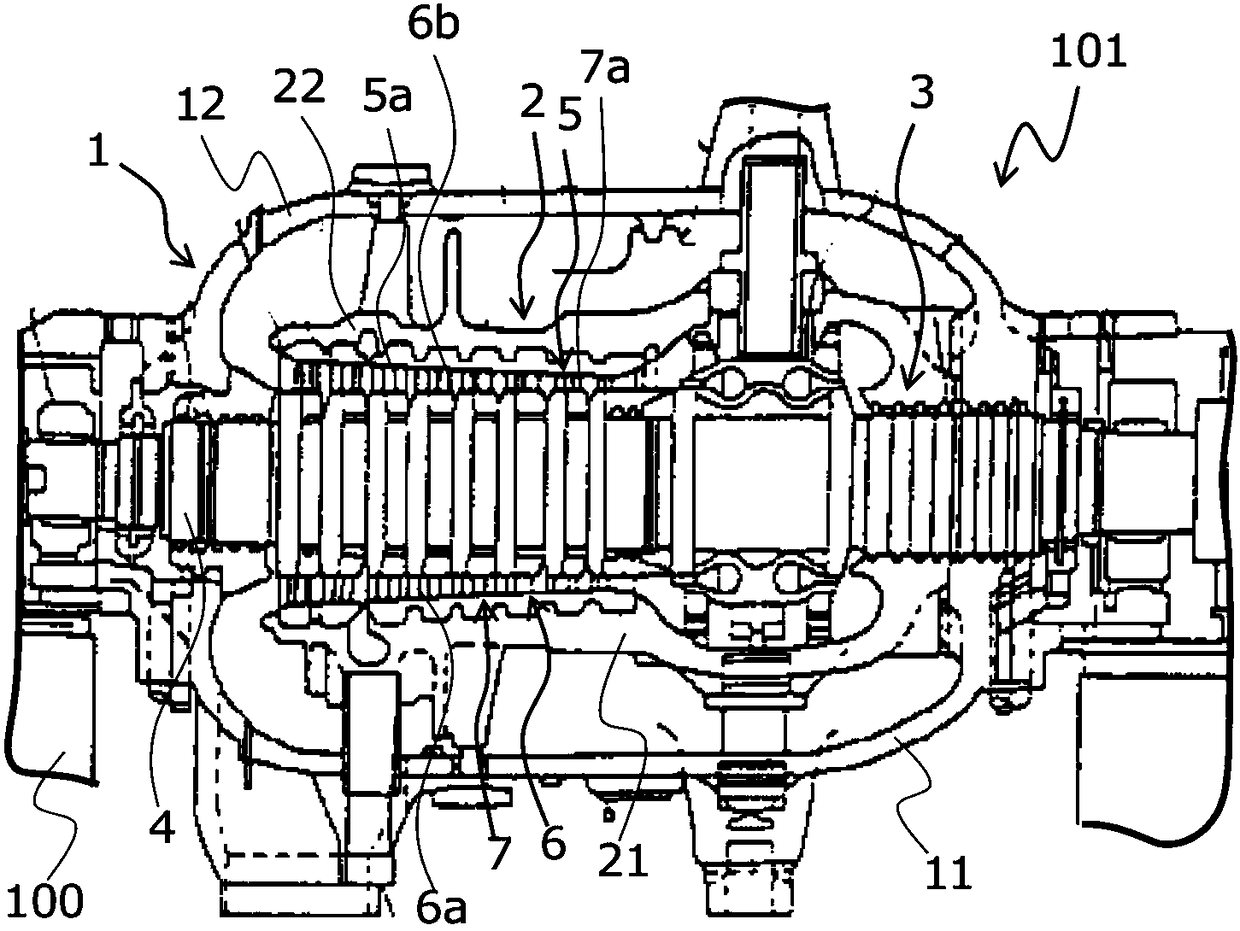

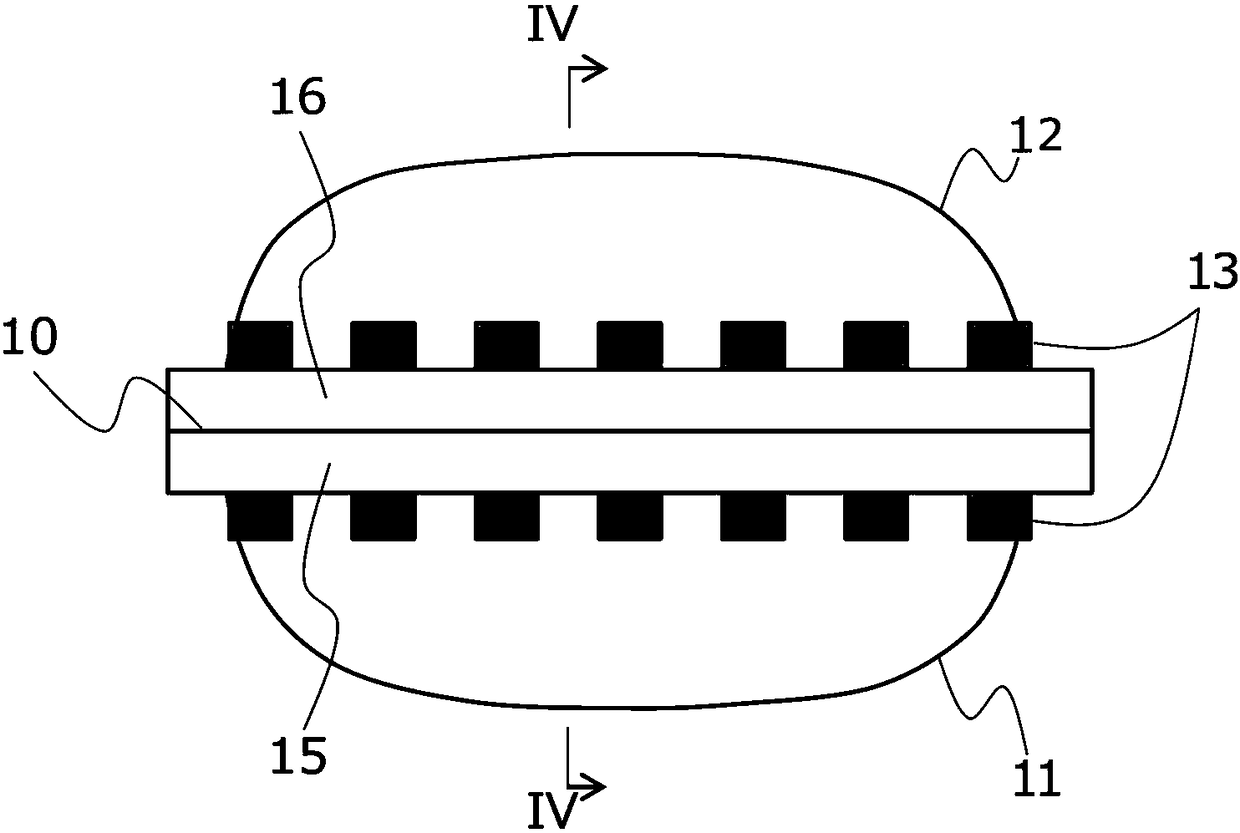

Turbine assembling method, turbine assembling auxiliary system, and recording medium

The invention is directed to maintaining the accuracy in the positional adjustment of a stationary part while shortening a turbine assembly period through the omission of the temporary assembly of a casing. A assembling method includes gaining measurement data on the configuration of a casing upper half part not fastened to a casing lower half part; gaining measurement data on the configuration ofthe casing lower half part in an open state in which the casing upper half part and a rotor are removed and in which a stationary part is mounted; comparing measurement data on the configuration of the casing upper half part and the casing lower half part with simulation data on the configuration of the casing upper half part and the casing lower half part previously obtained to select simulationdata closest to the measurement data on the configuration of the casing upper half part and the casing lower half part; calculating, based on the selected simulation data, a change amount of the configuration of the casing upper half part and the casing lower half part when the casing upper half part is fastened to the casing lower half part in the open state; and adjusting the installation position of the stationary part inside the casing taking into account the calculated change amount.

Owner:MITSUBISHI POWER LTD

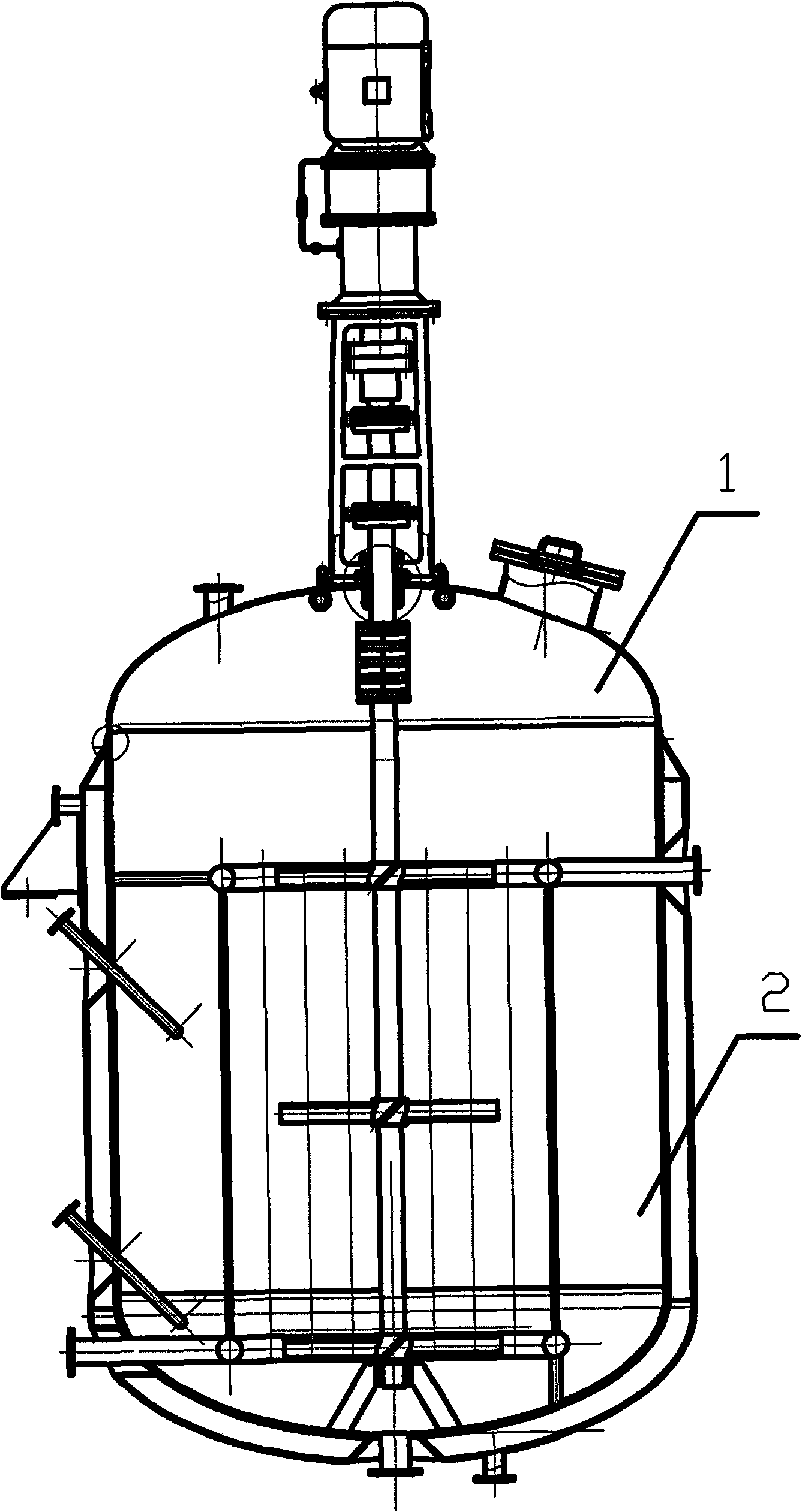

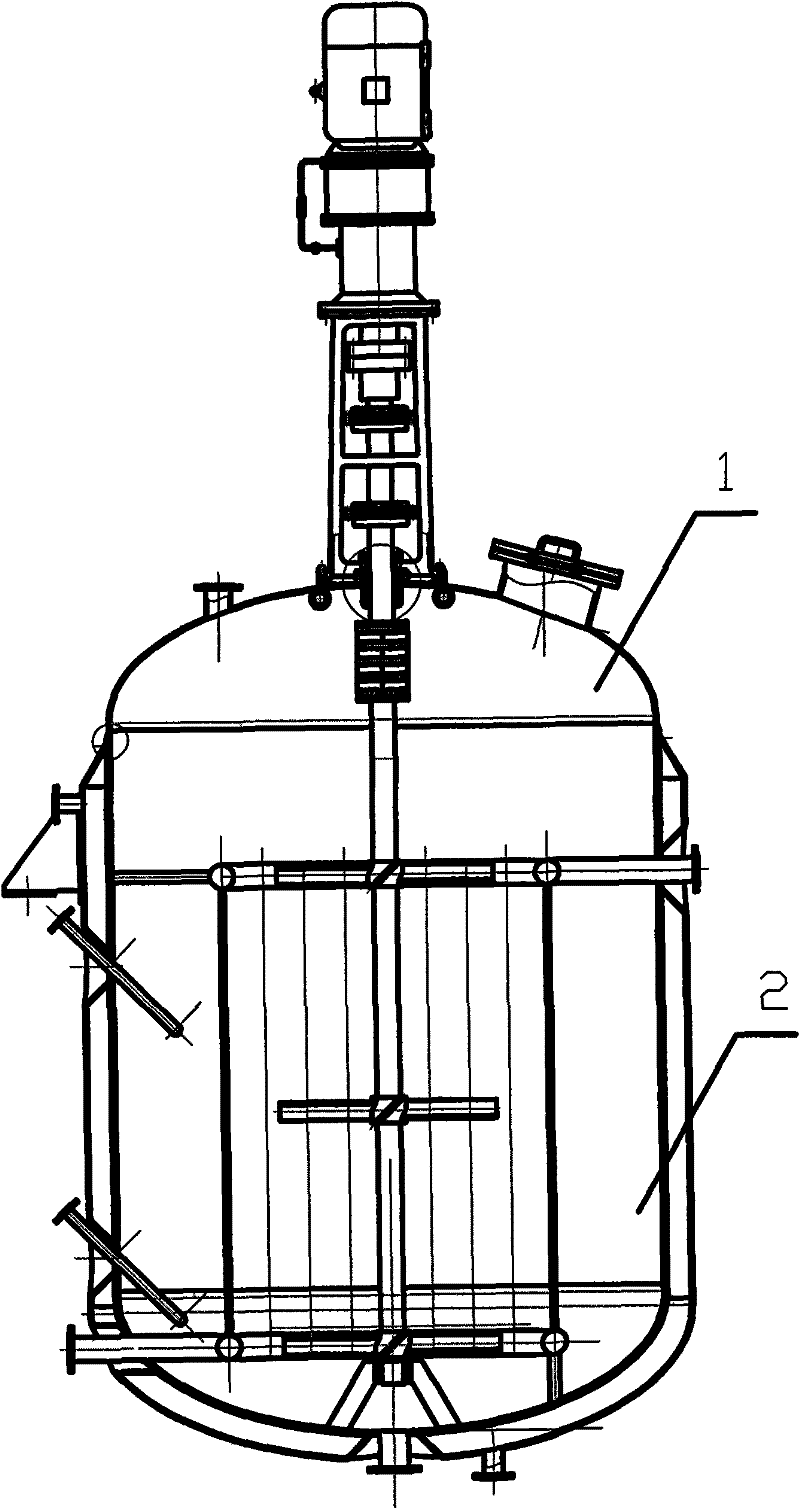

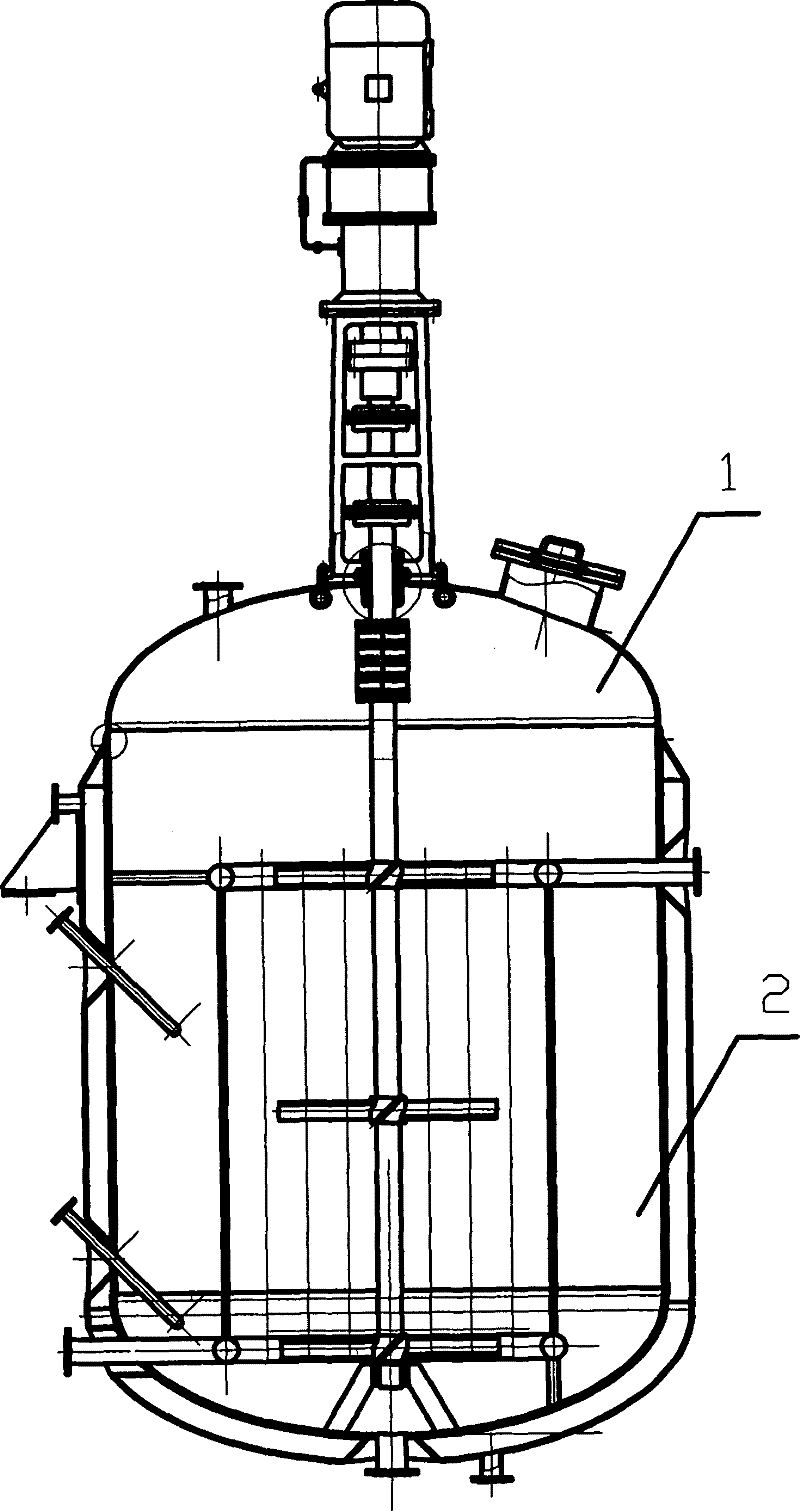

Assembly technique for head sealing cover and kettle of stock solution crystallizer

The invention discloses an assembly technique for a head sealing cover and a kettle of a stock solution crystallizer, which comprises the following steps of: according to the technique requirement, the head sealing cover is manufactured; according to the shape of the head sealing cover and the arrangement position of an adapter or a pipeline interface on the head sealing cover, an assembling supporting plate is manufactured; the head sealing cover is inversely arranged on the assembling supporting plate; the kettle is manufactured, lifted by a lifting device and inversely arranged on the head sealing cover; the position of the kettle is regulated; the contact site between the kettle and the head sealing cover is tightly jointed by depending on the self weight of the kettle; according to the technique requirement, the welding is carried out to cause the head sealing cover and the kettle to be connected into one body. In the assembly technique, the kettle is inversely arranged on the head sealing cover, and the self weight of the kettle is used for compressing the head sealing cover so that the kettle and the head sealing cover are tightly jointed, thus effectively reducing the crack between the kettle and the head sealing cover, being beneficial for the welding operation of the next step, preventing the deformation of the head sealing during welding, having more obvious protection effect on the head sealing cover, shortening the assembling working period and reducing the manufacture cost of equipment.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

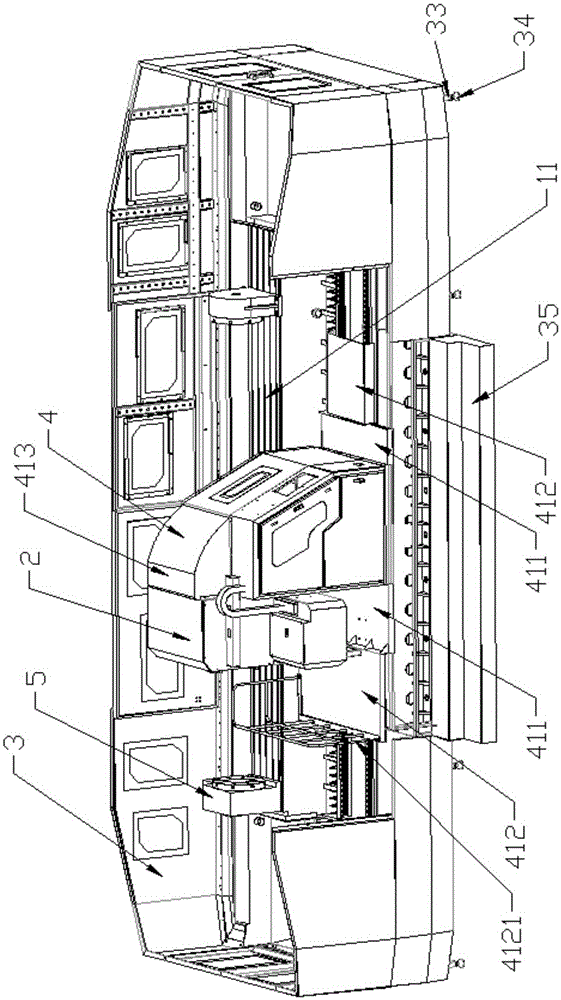

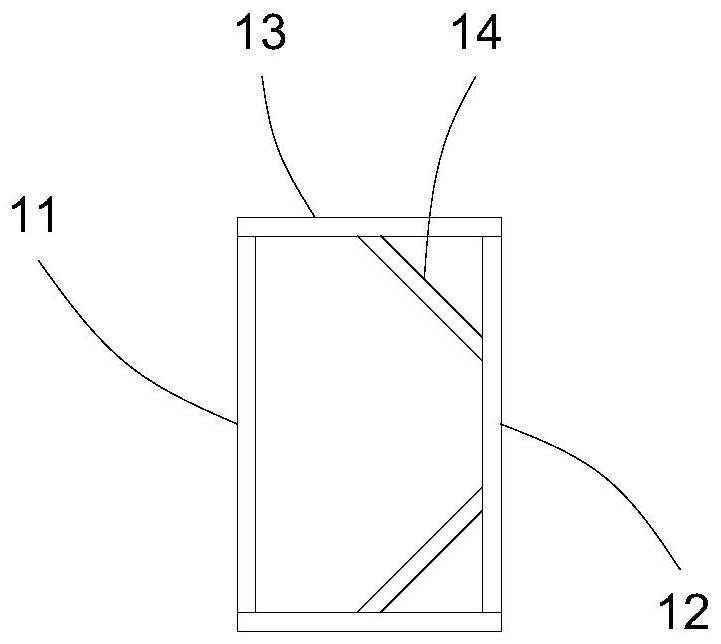

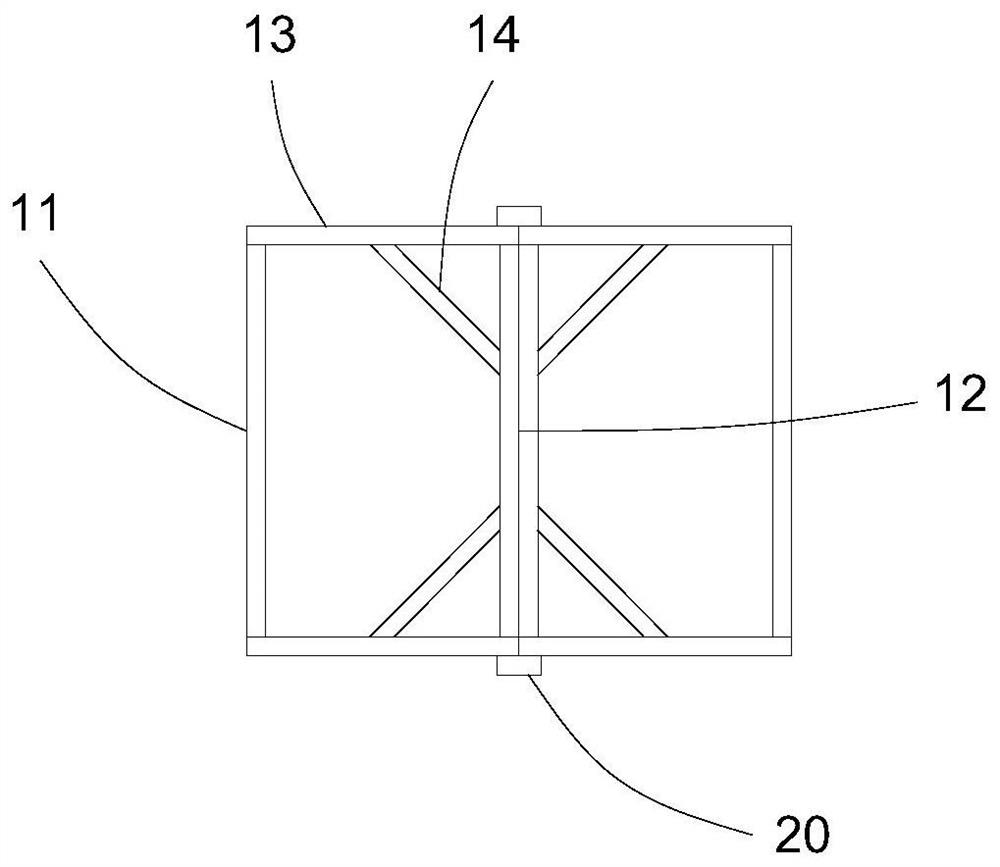

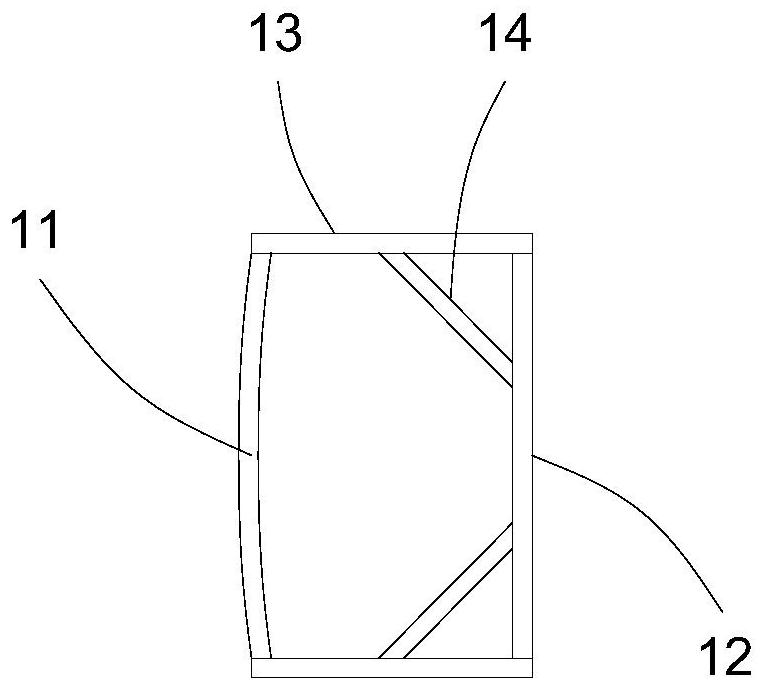

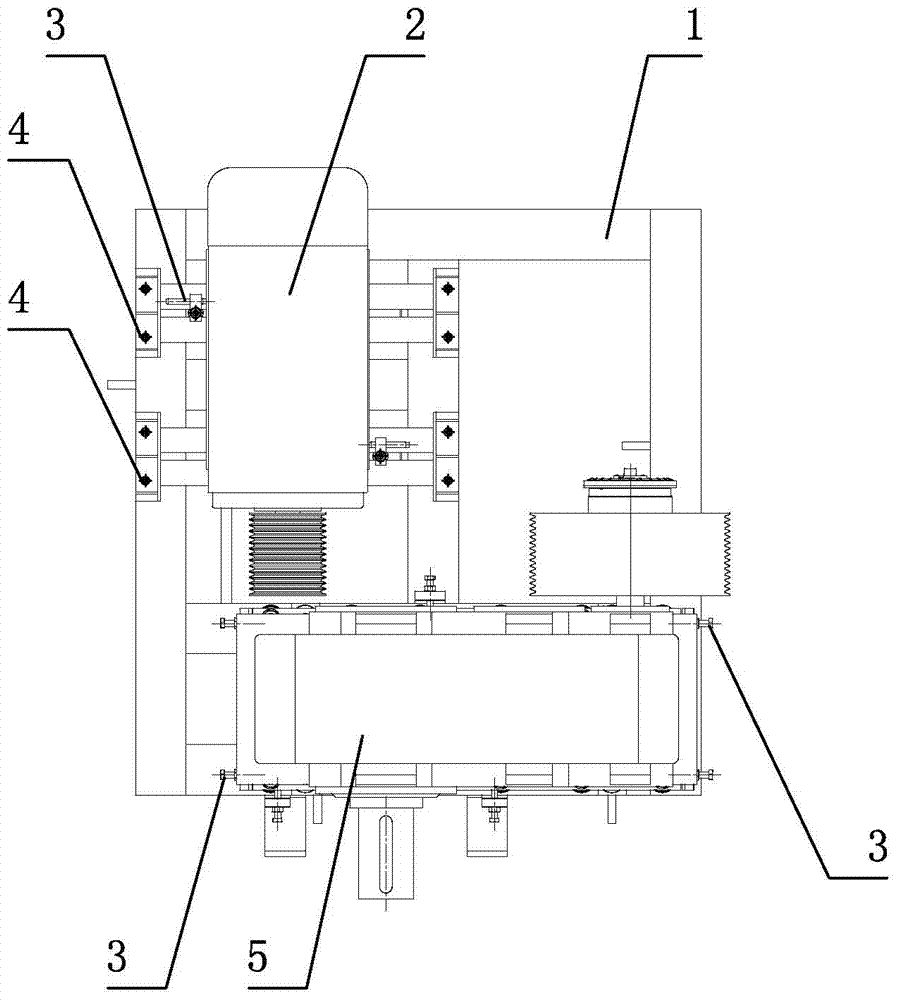

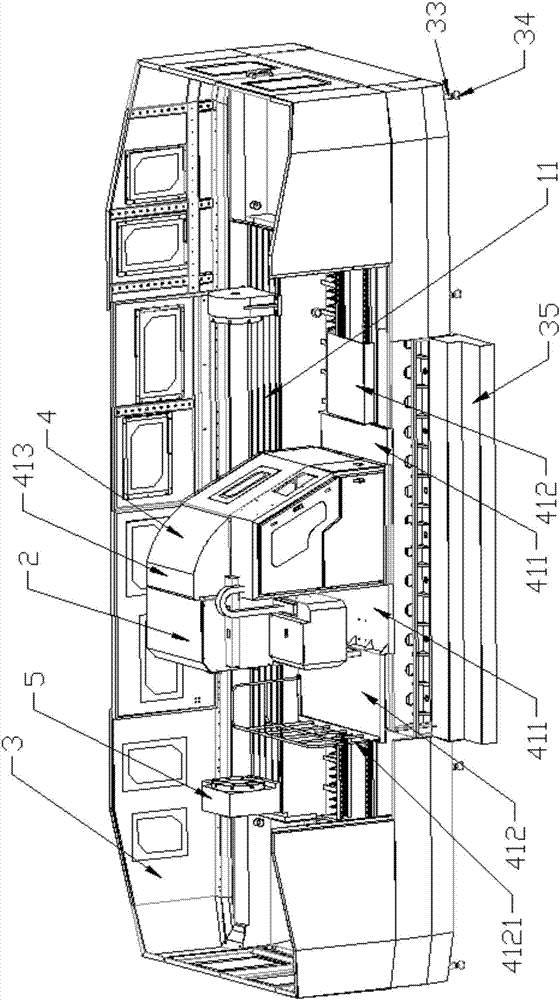

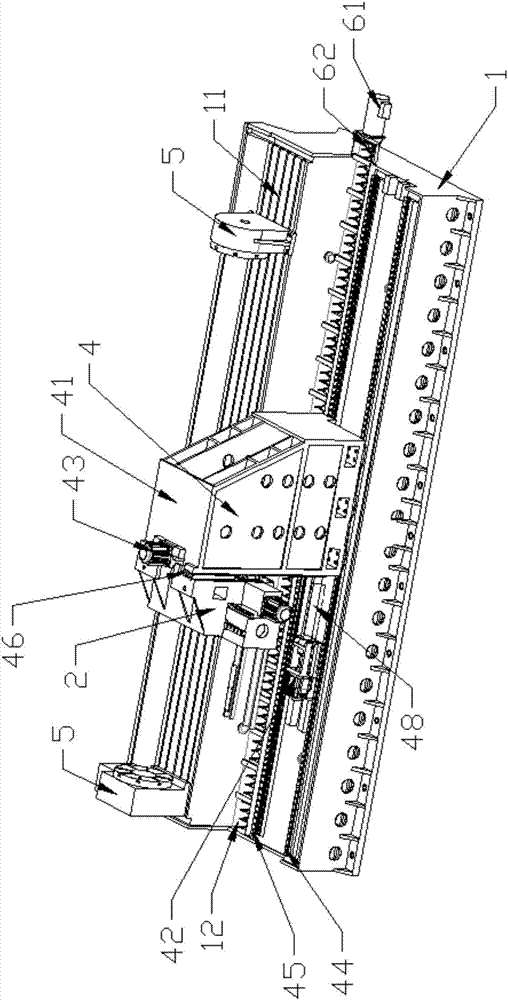

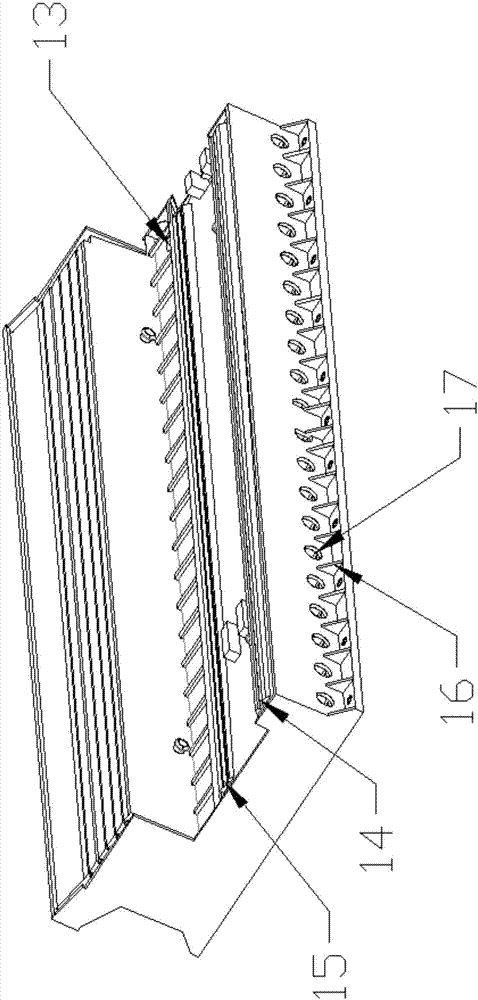

Horizontal machining center

ActiveCN105234682AGood rigidityGood stabilityMachine tool componentsLarge fixed membersMachining processEngineering

The invention provides a horizontal machining center. The horizontal machining center comprises a base, a main shaft head assembly and a stand column assembly. The stand column assembly is arranged on one side of the upper portion of the base. The stand column assembly is connected with the base in a sliding manner. The end, far away from the stand column assembly, of the upper portion of the base is provided with a workbench. The arrangement direction of the workbench is the same as the sliding direction of the stand column assembly. The main shaft head assembly is arranged on one side of the stand column assembly. The main shaft head assembly faces the workbench and is perpendicular to the X direction end face of the workbench. The main shaft head assembly is connected to the stand column assembly in a sliding manner. The main shaft head assembly comprises a main shaft box and a main shaft. The main shaft box is connected with the main shaft in the Z axis direction in a sliding manner. The main shaft can move in the X direction, the Y direction and the Z direction; and the workbench and the base are integrated, rigidity is good, a rotating table is arranged on the workbench, a large and heavy part can be completely machined though one time of clamping, and precision is high.

Owner:精诺(天津)数控科技有限公司

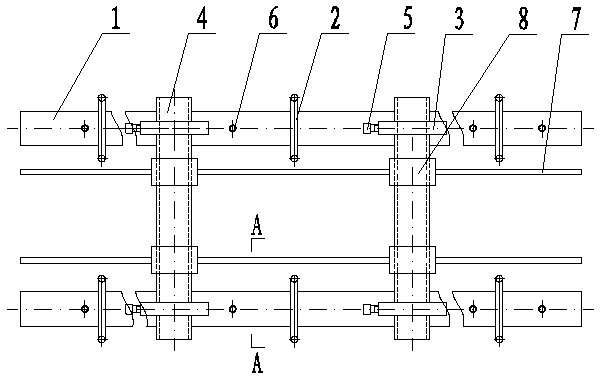

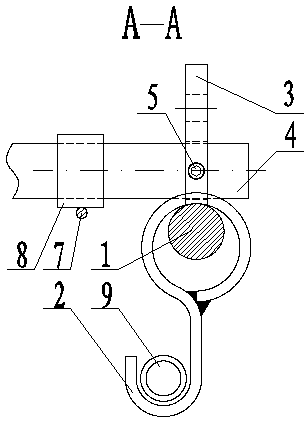

Snakelike tube panel lifting device

The invention relates to the technical field of garbage waste heat boiler air pre-heater manufacturing, and discloses a snakelike tube panel lifting device. The snakelike tube panel lifting device comprises two round bearing beams, the round bearing beams are sleeved with a plurality of lifting hooks, at least two lifting lugs are welded on each round bearing beam, and the lifting hooks can hook bends at two ends of a snakelike tube panel. The snakelike tube panel lifting device is simple in structure and convenient to operate, ensures the lifting stability of the snakelike tube panel, prevents the tube panel from deforming in the process of lifting, and ensures the quality of the tube panel.

Owner:SICHUAN CHUANGUO BOILER

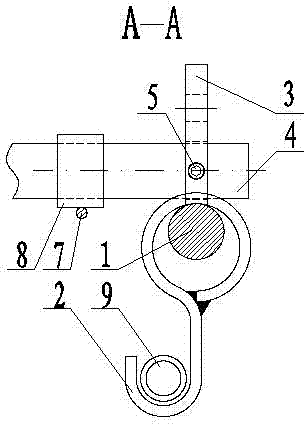

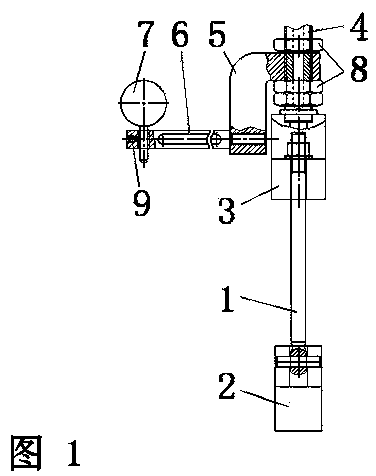

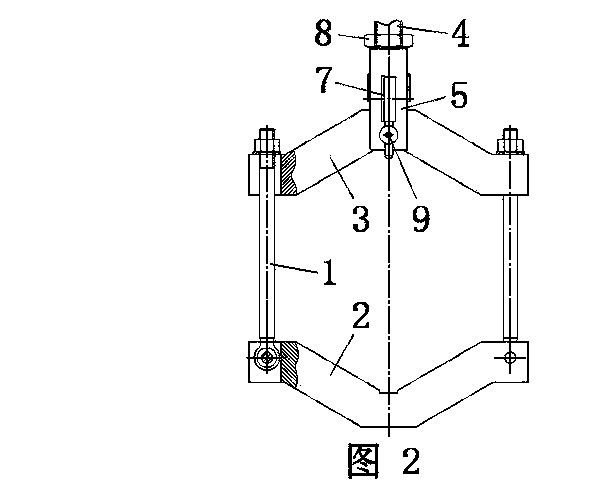

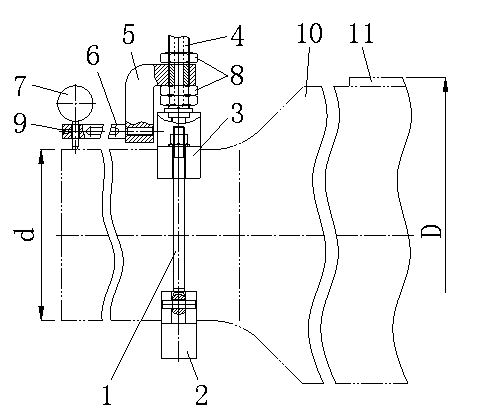

Measuring tool and measuring method for measuring revolution excircle of roller of reaming device

ActiveCN103776343AReduce labor intensityLarge measuring rangeMechanical diameter measurementsDesign standardEngineering

This invention discloses a measuring tool and measuring method for measuring revolution excircle of a roller of a reaming device. The measuring tool comprises a lower V-shaped iron (2) and an upper V-shaped iron which are connected through a bolt; the center of the top surface of the upper V-shaped iron is provided with a supporting rod; a measurement seat (5) which can be moved axially on the supporting rod is positioned on the supporting rod; at least two nuts are arranged on the supporting rod; a measurement rod (6) is arranged on the measurement seat; a measurement meter is positioned on the measurement rod. The invention can perform measurement on a series of product with various specifications through one set of measurement tools and replaces existing hundreds of ring gauges. That the measurement standard is relatively matched with the design standard can guarantee the coaxiality between the roller revolution excircle and a main body, and the measurement accuracy can be 0.05 millimeter and the product quality reliability can be increased. The operation for measuring the three-roller reaming device is simple, accurate, labor-saving, and time-saving, and is applicable to measuring the relatively large diameter of the revolution excircle of other rollers.

Owner:GUIZHOU GAOFENG GASOLINEEUM MACHINERY

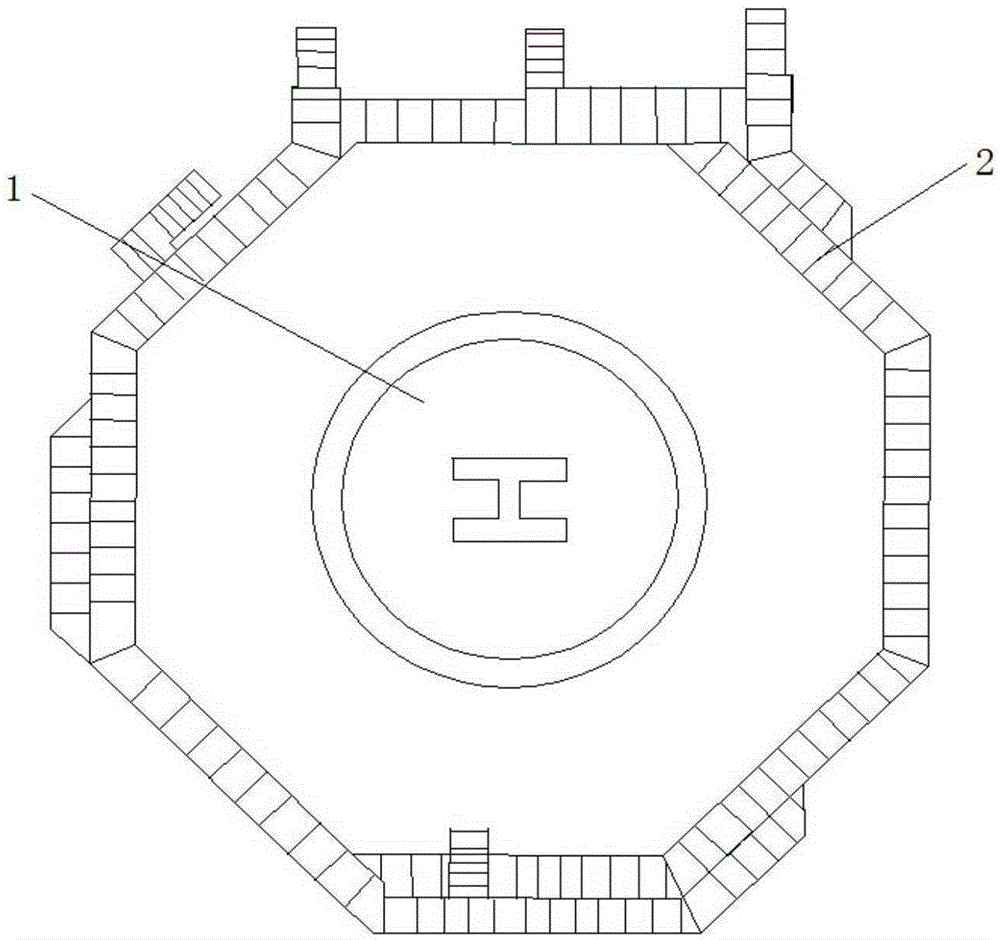

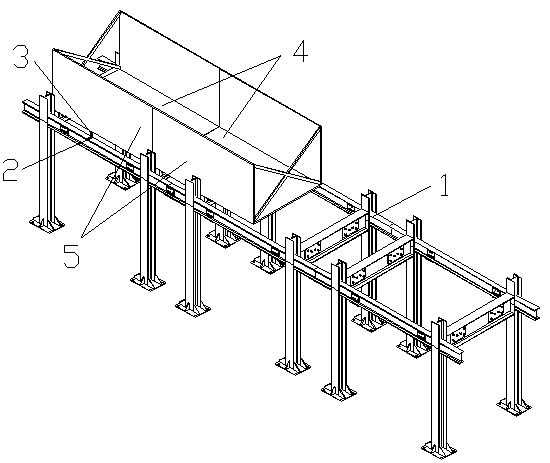

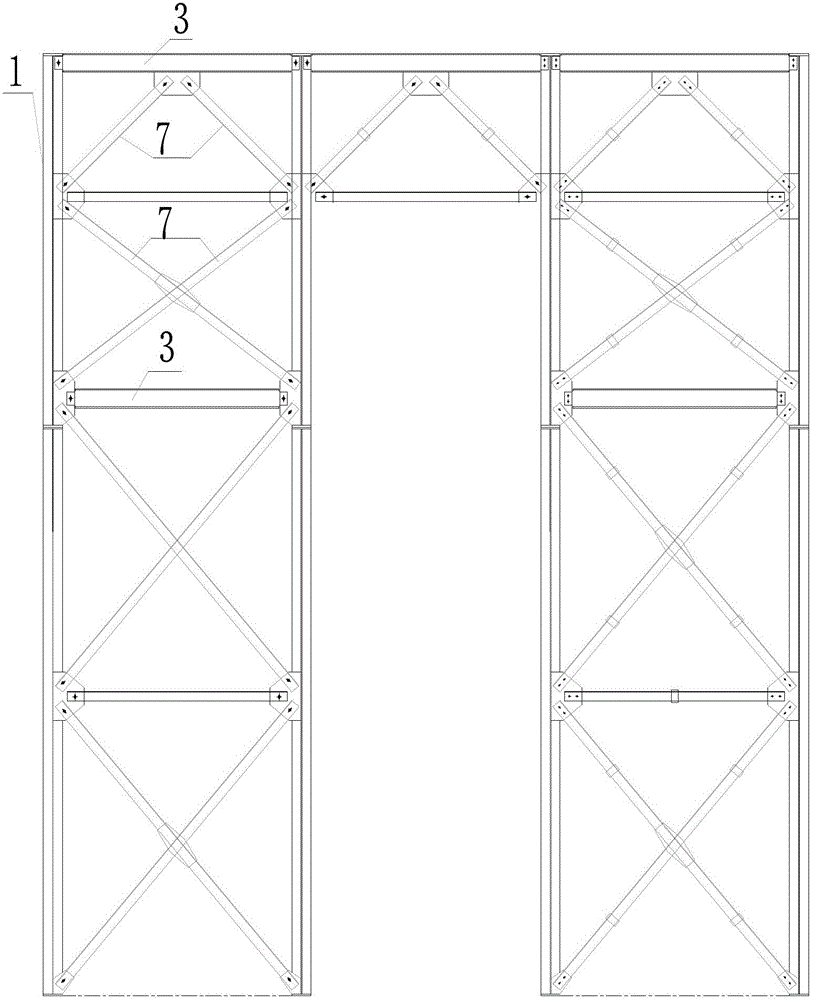

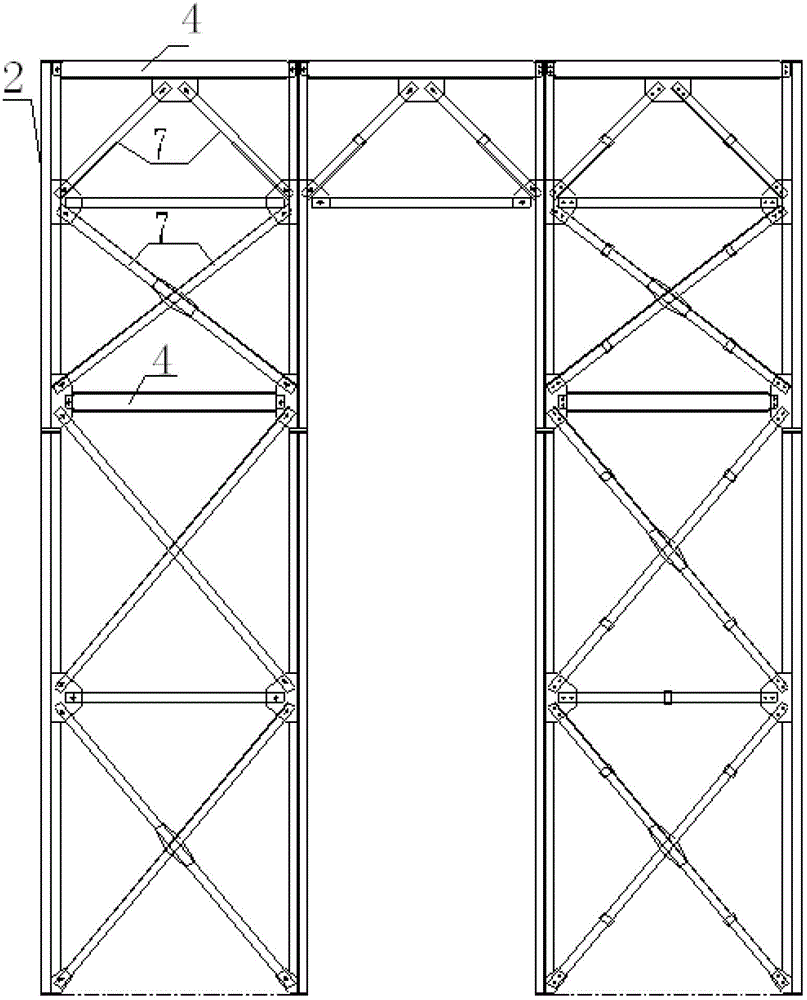

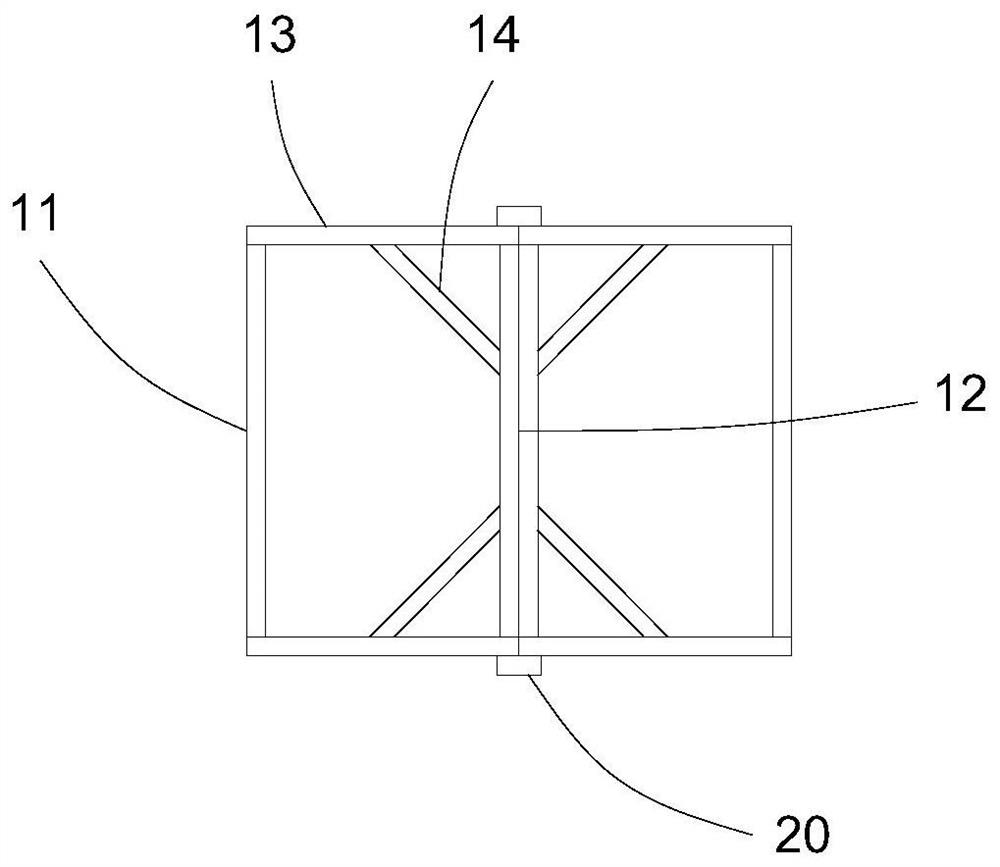

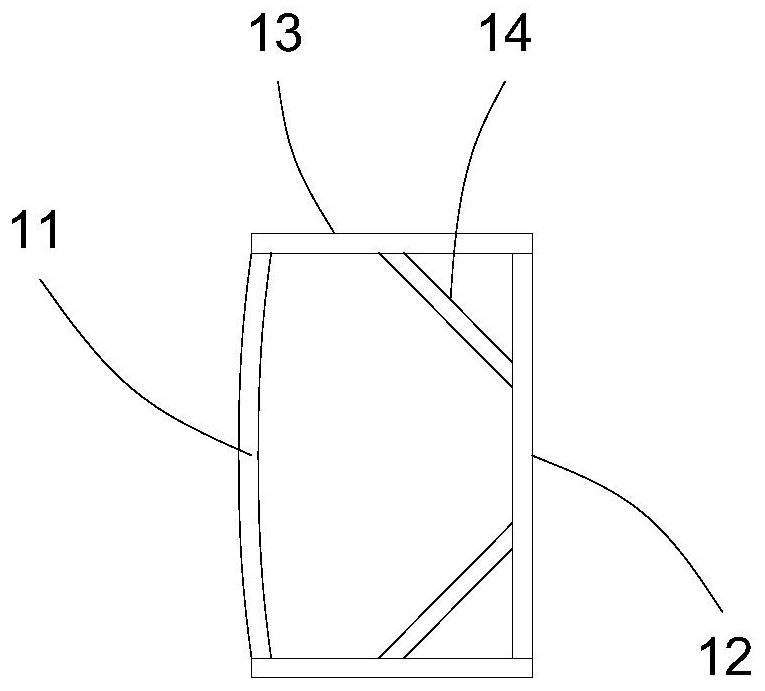

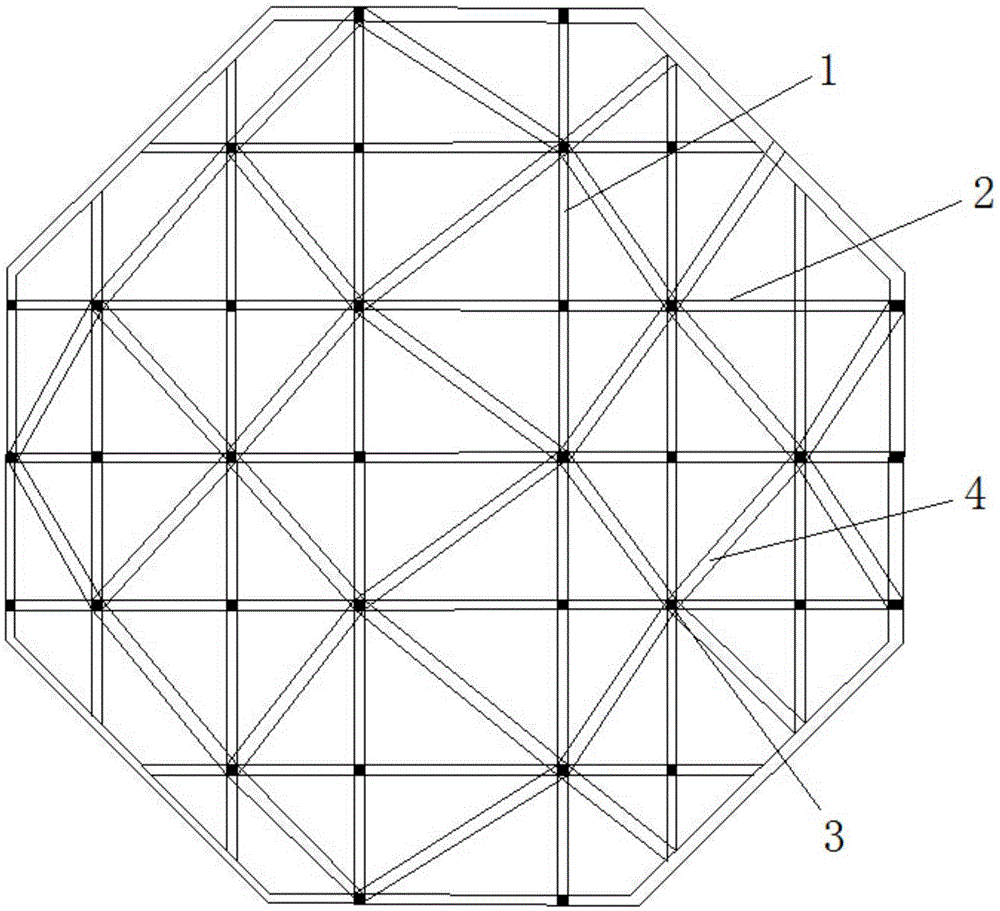

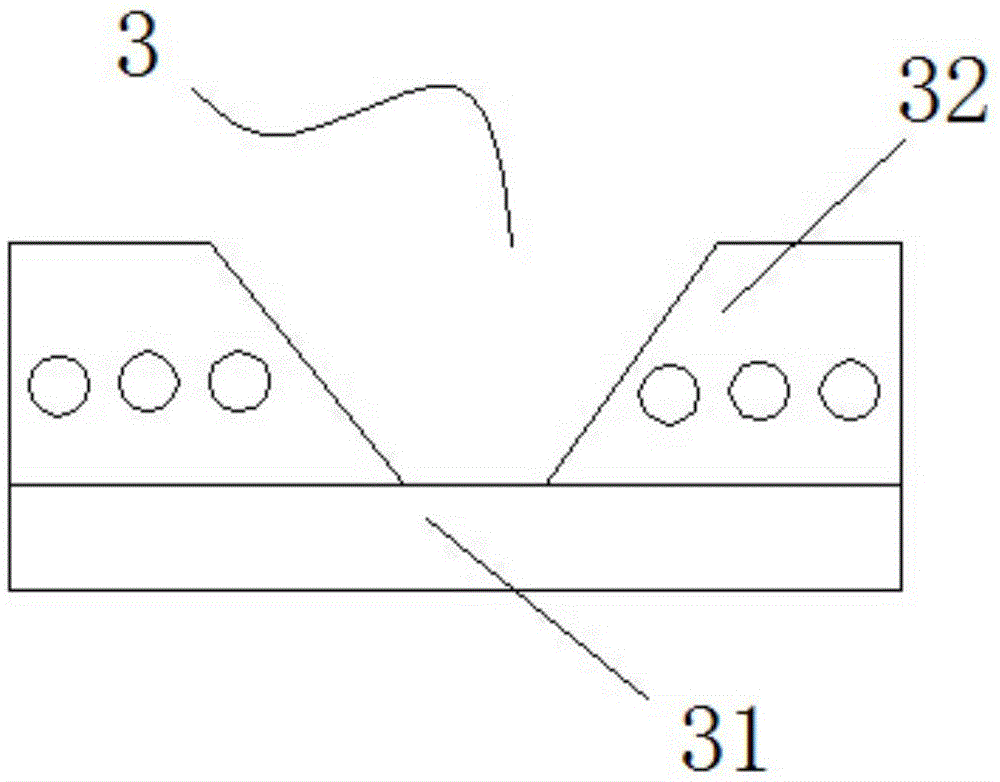

Helipad supporting system

InactiveCN105350463AEasy to assembleLighten the loadHelicopter landing platformSupporting systemEngineering

The invention discloses a helipad supporting system. The helipad supporting system comprises a plurality of sets of upper truss frames, a plurality of sets of lower truss frames, supporting frames, upper connecting frames and lower connecting frames, wherein the upper truss frames and the lower truss frames are in up-down parallel arrangement; the supporting frames are supported between the upper truss frames and the lower truss frames; one upper connecting frame is perpendicularly arranged between the two adjacent upper truss frames; one lower connecting frame is perpendicularly arranged between the two adjacent lower truss frames; one reinforcing device is arranged between each upper truss frame and each supporting frame, one reinforcing device is arranged between each lower truss frame and each supporting frame, and the upper connecting frames are fixedly connected with the upper truss frames through the reinforcing devices, and the lower connecting frames are fixedly connected with the lower truss frames through the reinforcing devices. According to the helipad supporting system disclosed by the invention, all structures are assembled through the reinforcing devices, so that the safety and the stability of the system are improved, the situation that corrosion and crackles are generated due to stress produced during welding and assembling is avoided, the helipad supporting system is rapid and efficient, and the assembling construction period is shortened.

Owner:台澳铝业(台山)有限公司

A serpentine tube panel lifting device

Owner:SICHUAN CHUANGUO BOILER

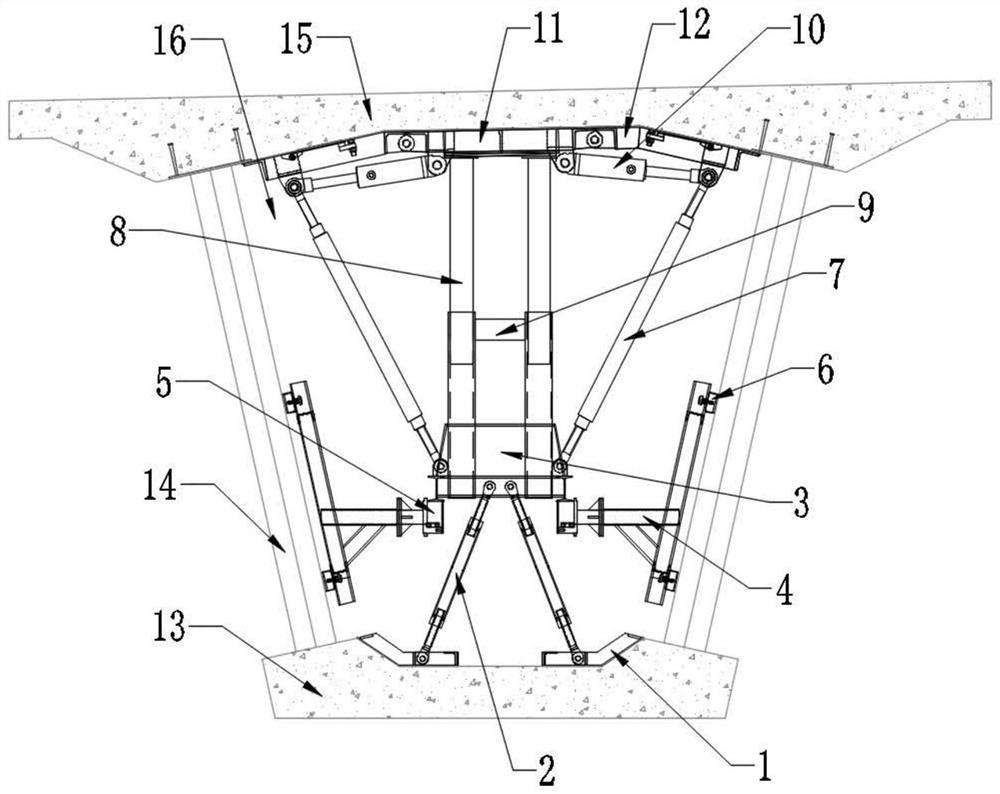

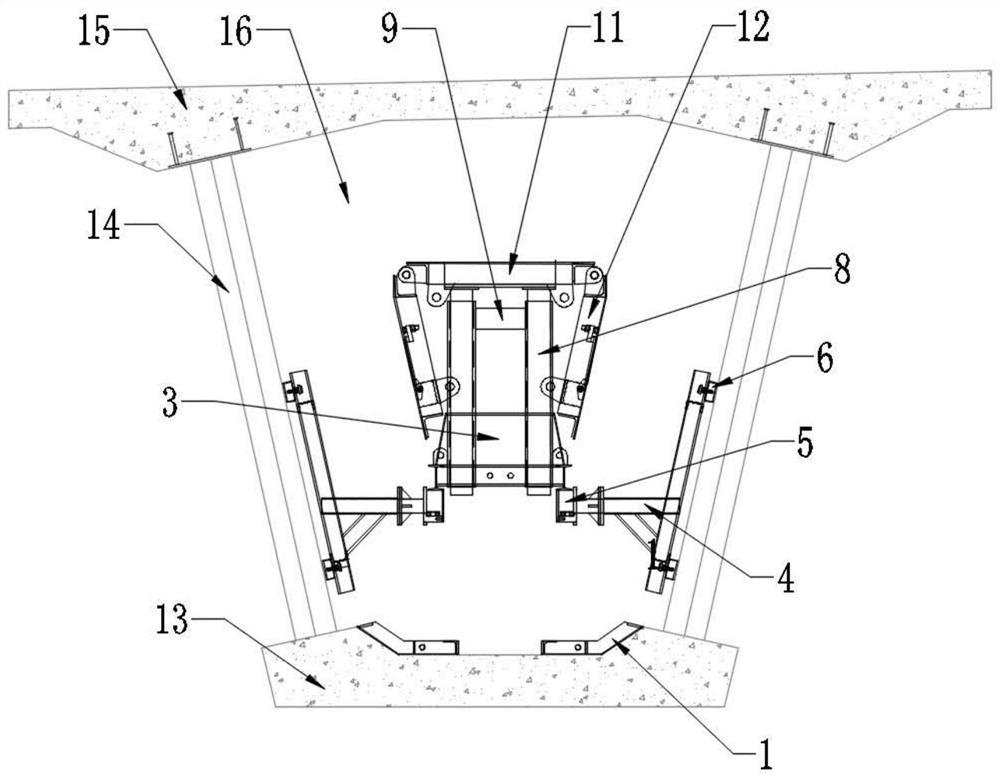

Hydraulic inner formwork of assembled corrugated steel web combined box girder

ActiveCN113944324AHigh reuse rateReduce the difficulty of operationHydro energy generationForms/shuttering/falseworksArchitectural engineeringHydraulic ram

The invention discloses a hydraulic inner formwork of an assembled corrugated steel web combined box girder. The hydraulic inner formwork comprises corrugated steel webs, wherein the corrugated steel webs are symmetrically supported between a concrete top plate and a concrete bottom plate; a lower bottom die is fixedly arranged on the upper surface, in a box chamber, of the concrete bottom plate, the lower bottom die is symmetrically and movably connected with first supporting rods extending upwards, and the top ends of the first supporting rods are movably connected with sliding beams; the sliding beams are placed on symmetrical rail pulleys, the rail pulleys are connected with the inner walls of the corrugated steel webs on the same side through supports, the sliding beams are symmetrically and fixedly provided with first hydraulic oil cylinders which are vertically upward, and the top ends of the first hydraulic oil cylinders are jointly connected with a first upper bottom die abutting against the bottom end of the concrete top plate; and the two sides of the first upper bottom die are rotationally connected with second upper bottom dies abutting against the bottom end of the concrete top plate. The hydraulic inner formwork of the corrugated steel web combined box girder can be used for quickly erecting the formwork, saves labor and is convenient to disassemble and assemble.

Owner:中建桥梁有限公司 +1

Assembly technique for head sealing cover and kettle of stock solution crystallizer

The invention discloses an assembly technique for a head sealing cover and a kettle of a stock solution crystallizer, which comprises the following steps of: according to the technique requirement, the head sealing cover is manufactured; according to the shape of the head sealing cover and the arrangement position of an adapter or a pipeline interface on the head sealing cover, an assembling supporting plate is manufactured; the head sealing cover is inversely arranged on the assembling supporting plate; the kettle is manufactured, lifted by a lifting device and inversely arranged on the headsealing cover; the position of the kettle is regulated; the contact site between the kettle and the head sealing cover is tightly jointed by depending on the self weight of the kettle; according to the technique requirement, the welding is carried out to cause the head sealing cover and the kettle to be connected into one body. In the assembly technique, the kettle is inversely arranged on the head sealing cover, and the self weight of the kettle is used for compressing the head sealing cover so that the kettle and the head sealing cover are tightly jointed, thus effectively reducing the crackbetween the kettle and the head sealing cover, being beneficial for the welding operation of the next step, preventing the deformation of the head sealing during welding, having more obvious protection effect on the head sealing cover, shortening the assembling working period and reducing the manufacture cost of equipment.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

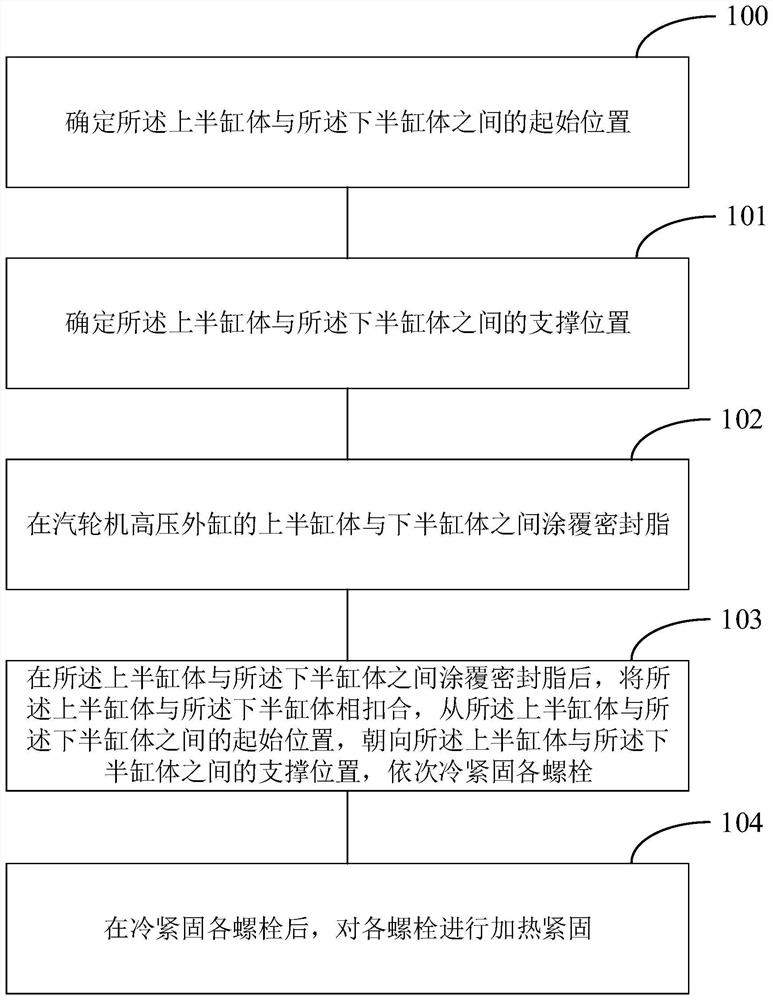

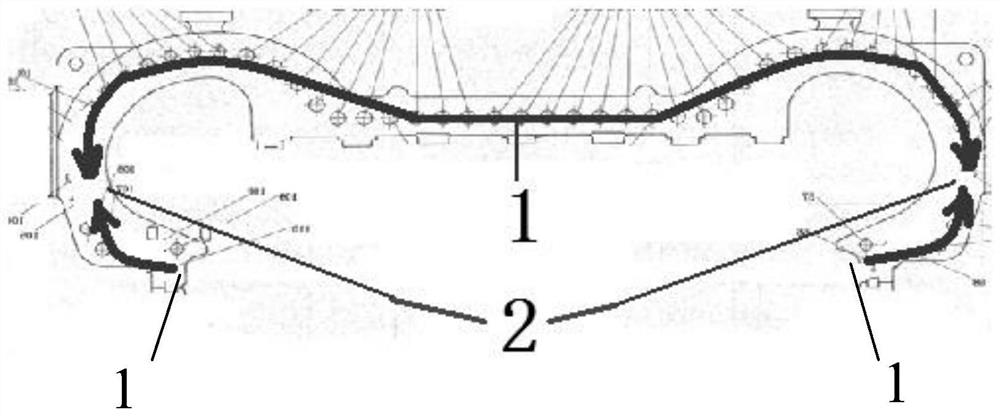

Nuclear turbine high-pressure outer cylinder split assembling method

ActiveCN112228169AImprove seal qualityAvoid reworkMachines/enginesEngine componentsNuclear powerClassical mechanics

The invention belongs to the technical field of nuclear power maintenance, and particularly relates to a nuclear turbine high-pressure outer cylinder split assembling method. In practice, the situation that the minimum sagging arc of the buckled state of an upper half cylinder body and a lower half cylinder body is not located at the two sides of a high-pressure outer cylinder of a turbine but located at a supporting position between the upper half cylinder body and the lower half cylinder body is found, so that the fastening operation space of other bolts arranged behind bolts at the supporting position in the fastening sequence is not enough by means of a method of a related technology, and the other bolts are not secured properly. According to the nuclear turbine high-pressure outer cylinder split assembling method, the bolts are sequentially fastened in a cold mode from a starting position between the upper half cylinder body and the lower half cylinder body of the high-pressure outer cylinder of the turbine to the supporting position between the upper half cylinder body and the lower half cylinder body, and sufficient operation space is effectively reserved for the fastening of the bolts at the supporting position, so that the sealing quality of assembly by the method is greatly improved, rework is avoided, and the assembly period is effectively shortened.

Owner:CNNC NUCLEAR POWER OPERATION MANAGEMENT +1

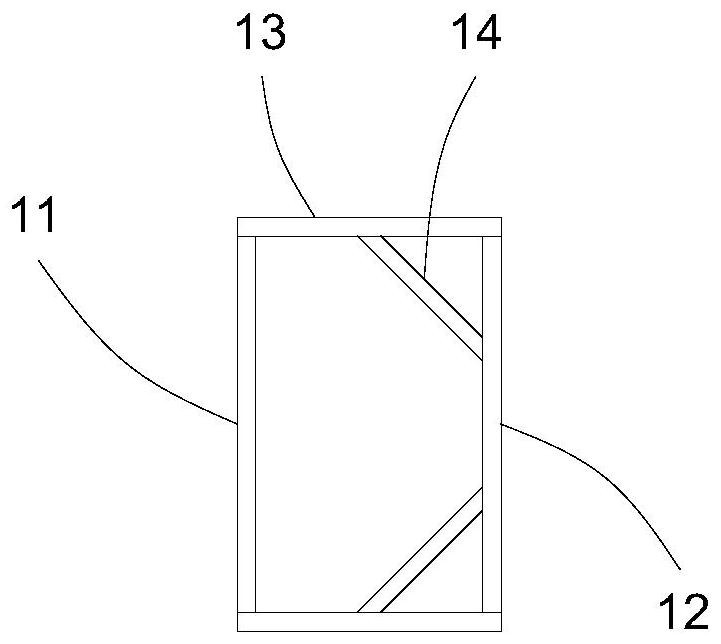

A single-sided assembly method for anti-deformation steel components

ActiveCN112355501BDimensions will not changeAccuracy requirements metWelding apparatusClassical mechanicsStructural engineering

The invention provides a deformation-resistant single-sided assembling method for steel members, comprising the following steps: preparing a plate; , Weld the connection between the oblique support plate and the side plate, and splicing the panel at the opening to obtain a pre-assembled frame; back-joint positioning, the back plate is closely spliced with the two pre-assembled frames, and the panel and the side are positioned by the clamping piece. The joints of the plates are welded, and after cooling and forming, the plate protrudes to the side away from the back plate to obtain a transition frame; the component is formed, the two transition frames are separated, and the joint between the back plate and the side plate is welded; Assemble the lateral support to one side of the panel, weld the joint, and restore the panel to flat after cooling and forming. The invention can realize deformation and anti-deformation actions in the process of welding and assembly, can ensure that the surface of the finally obtained steel component is flat and reliable, and can effectively save processing steps and correction costs.

Owner:GUANGDONG GRAND GREENBUILT TECH CO LTD

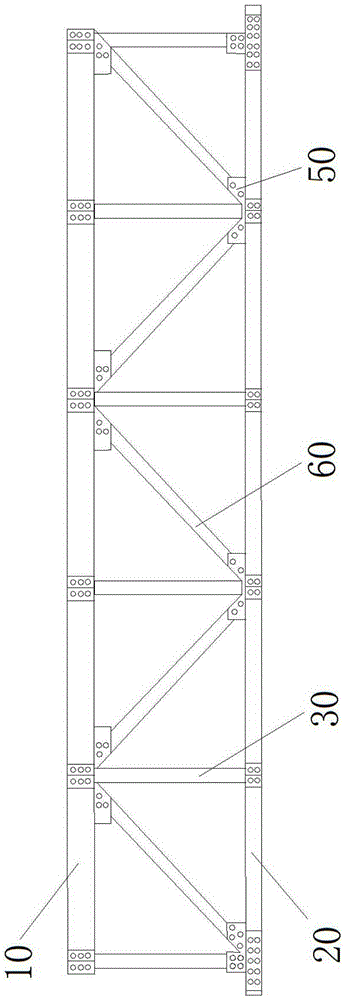

Corridor support system for helipad

InactiveCN106836030AEasy to assembleImprove securityHelicopter landing platformSupporting systemEngineering

The invention discloses a helipad corridor support system, which comprises a plurality of apron support frames, including a plurality of corridor support trusses and corridor diagonal braces, the corridor support trusses are fixed on the apron support frames, and the corridor slant One end of the support frame is fixedly connected by a reinforcement device at the lower end of the apron support frame, and the other end of the corridor diagonal brace is fixed on the corridor support truss. The helipad corridor support system of the present invention utilizes reinforcement devices, mounting seats, diagonal braces, etc. to assemble various structures, which not only improves the safety and stability of the structure, avoids corrosion and cracks caused by welding and assembly stress, but also is fast and efficient, shortening the Assembly period. The helipad corridor support system of the present invention can be easily and quickly assembled under the premise of ensuring a safe and reliable structure, and has strong practicability and market promotion value.

Owner:台澳铝业(台山)有限公司

Annealing furnace shell modular installation method

InactiveCN109207699AOvercome installation flawsEasy to installFurnace typesHeat treatment furnacesMetallurgyReference line

The invention discloses an annealing furnace shell modular installation method. The method comprises the following steps that firstly, a steel structure platform used for supporting an annealing furnace shell is erected, and a furnace shell bottom plate positioning line and a furnace shell wallboard reference line are marked; the annealing furnace shell which comprises several sequentially-connected furnace shell bottom plate modules and furnace shell wallboard modules is manufactured in a modular mode, and installation serial numbers are marked; the furnace shell bottom plate modules are hoisted to the steel structure platform in sequence and are adjusted and positioned according to the positioning line, the furnace shell wallboard modules corresponding to the furnace shell bottom plate modules are hoisted to the steel structure platform and are adjusted and positioned according to the reference line, the furnace shell bottom plate modules and the furnace shell wallboard modules are assembled through welding until welding assembling of all the furnace shell bottom plate modules and furnace shell wallboard modules is completed. According to the method, the defects of a traditionalsingle-piece installing mode of the annealing furnace shell are overcome, the assembling period is effectively shortened, and the assembling efficiency is improved, the size precision and quality of the installation of the furnace shell are ensured, and the subsequent installation operation of equipment in the furnace shell is facilitated.

Owner:CHINA MCC20 GRP CORP

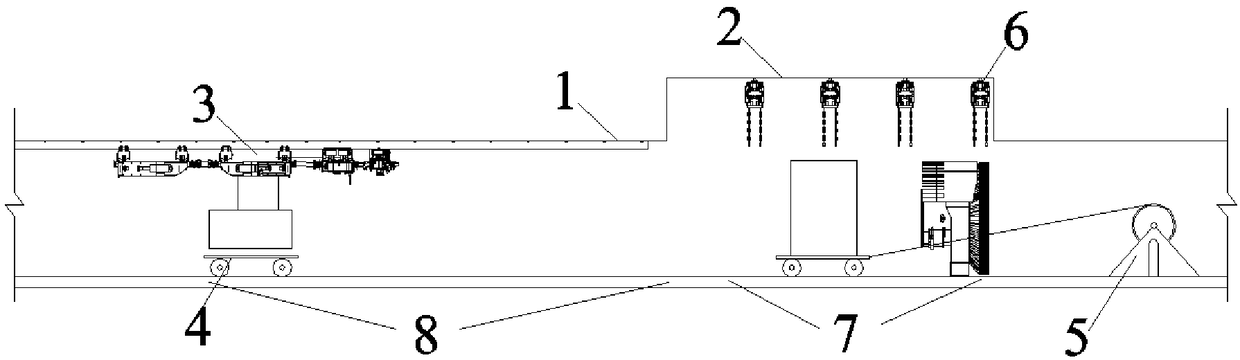

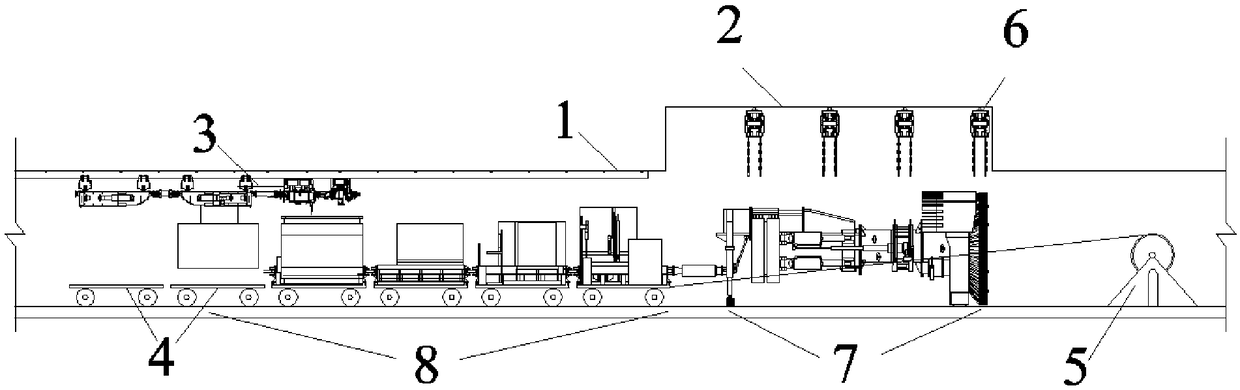

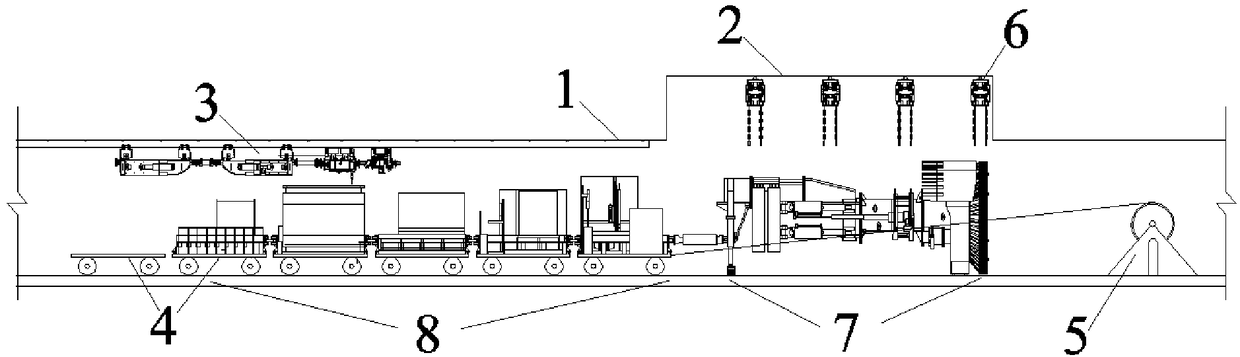

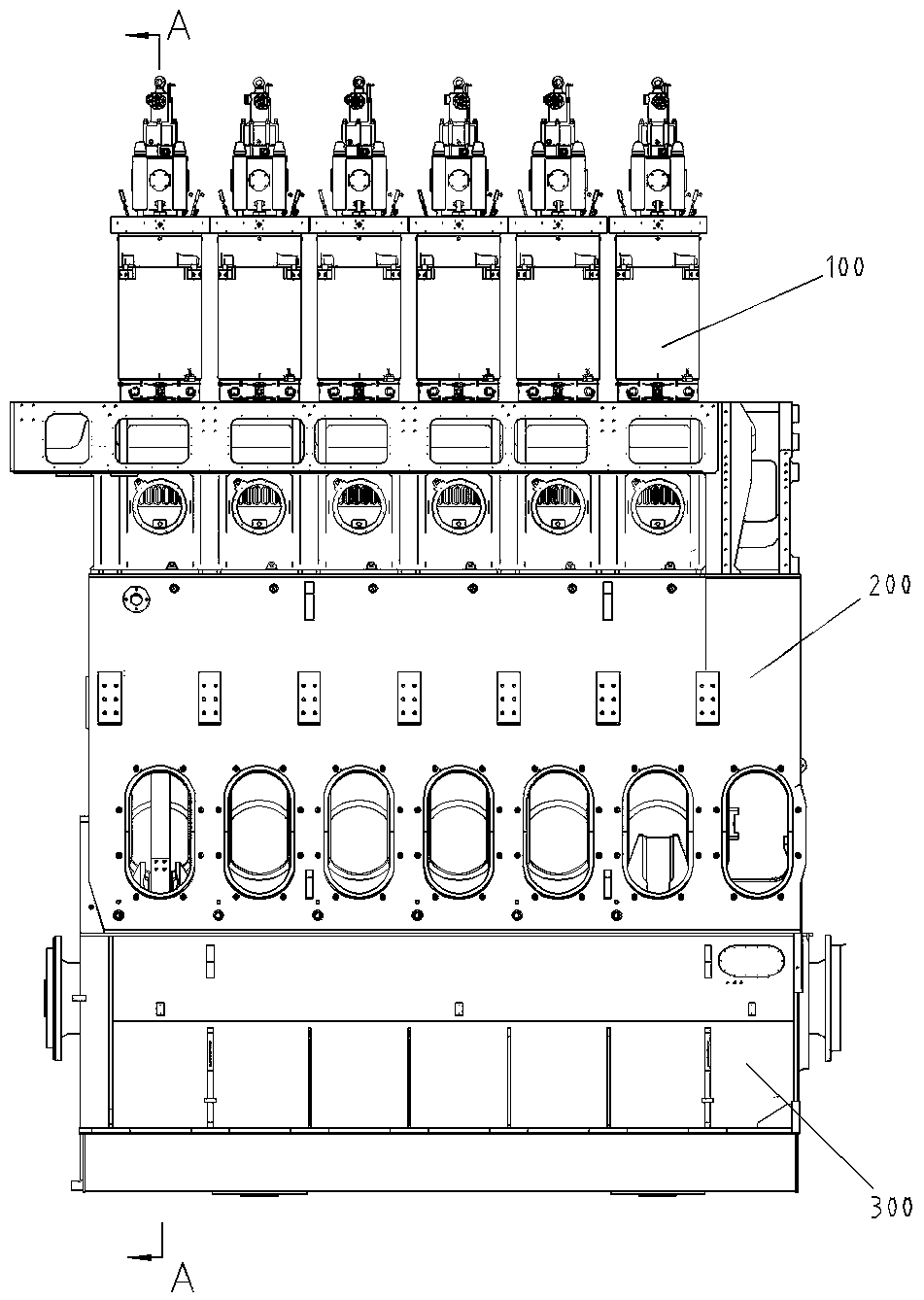

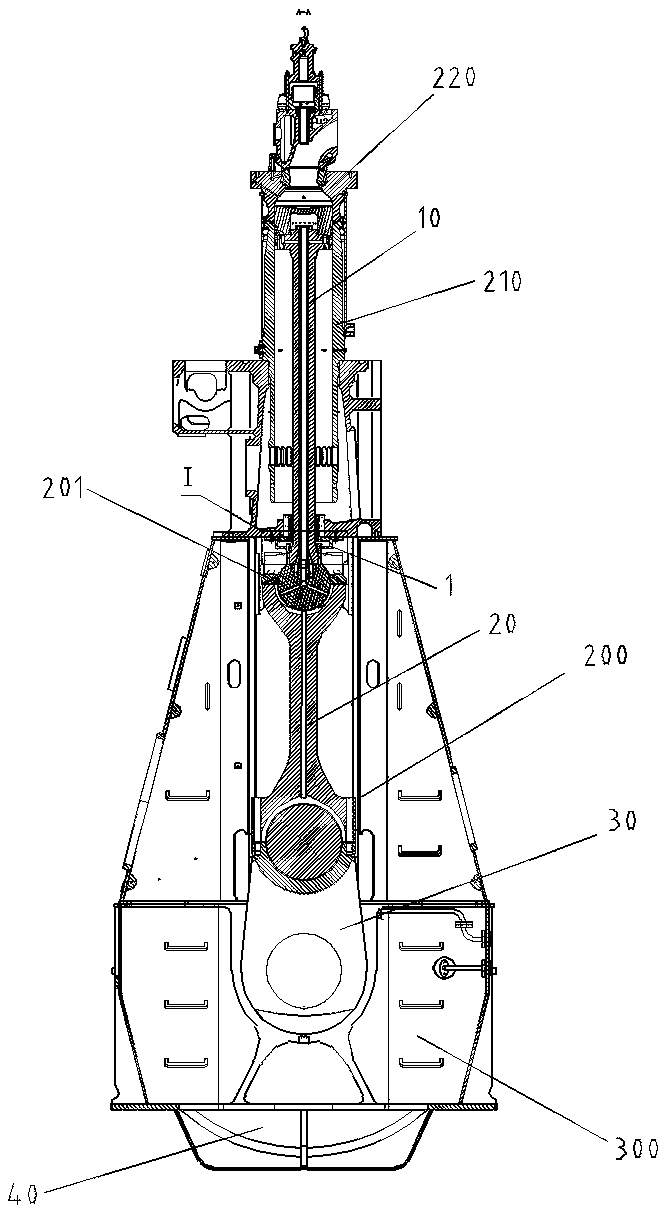

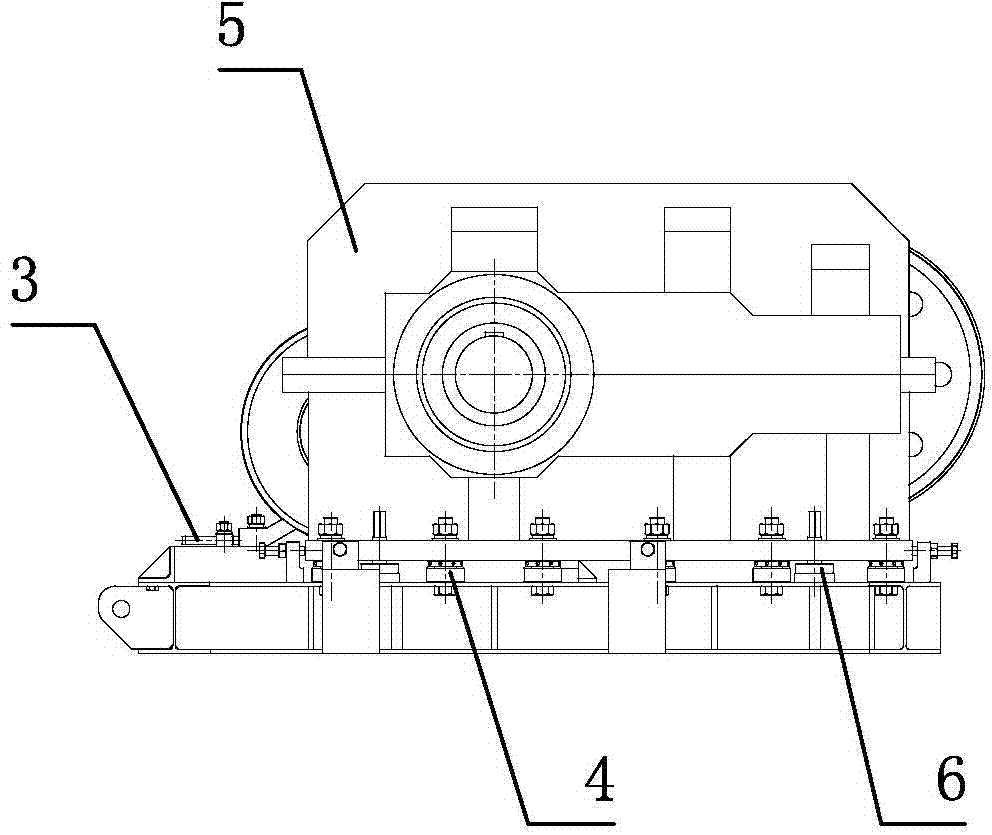

An underground mine tbm assembly construction method

The invention provides an underground mine TBM assembly construction method. The underground mine TBM assembly construction method comprises the following steps that (1) chamber assembly is constructed, and an existing roadway of an underground mine and a chamber assembly expanding excavation section serve as a TBM assembly chamber; and the chamber assembly expanding excavation section is formed through expanding excavation of one end of the existing roadway. (2) TBM parts transportation is constructed, TBM parts are placed on a platform truck through a monorail hoist, and a winch connected with the platform truck is pulled to a preinstalled position. (3) TBM parts assembly is constructed, the TBM parts are installed through a lifting pulley or the monorail hoist, and the TBM installation is finally completed. According to the underground mine TBM assembly construction method, the existing roadway is used as the assembly chamber, a vertical shaft is not needed to be re-excavated on an assembly site, and the feasibility of construction is improved; and large scale equipment of a gantry crane and the like are not needed to be installed under the shaft by using small scale installation equipment of the monorail hoist, the lifting pulley, the winch and the like, the work amount of the expanding excavation and transformation is small, the assembly construction period is shortened, and meanwhile the engineering cost is saved.

Owner:ANHUI UNIV OF SCI & TECH +1

How to use the on-hook tooling of the piston assembly of the marine low-speed diesel engine

The invention discloses a hanging tool for a marine low-speed diesel engine piston assembly and a method using the hanging tool. The hanging tool comprises brackets, a special bolt for piston connection and a gas cylinder body connecting bolt, wherein when the piston assembly is hung, the lower end of the special bolt for piston connection is screwed into a piston bottom pin, and the upper end ofthe gas cylinder body connecting bolt is screwed into a lower bottom plate of the gas cylinder body. The using method comprises the following steps of: separately fastening the brackets to the two sides of the piston bottom pin and the lower side surface of the gas cylinder body; 2) dropping the piston assembly, and supporting the piston assembly through the two brackets; 3) lifting the gas cylinder body onto the upper plane of the rack to fold; 4) enabling an in-machine operator and an outside-the-machine operator to cooperate with each other, and enabling a cross head of a connecting rod tobear weight of the piston assembly through a turning gear; and 5) fixedly connecting the cross head of the connecting rod to the piston assembly, and dismounting the brackets. According to the hangingtool and the method using the hanging tool disclosed by the invention, the potential safety hazards, due to the fact that the piston assembly and the gas cylinder cover are repeatedly dismounted anda travelling crane is lifted by many times, of overhead operation are avoided, the assembly period is shortened, assembly cost is reduced, and assembly efficiency and assembly safety are improved.

Owner:CSSC MARINE POWER

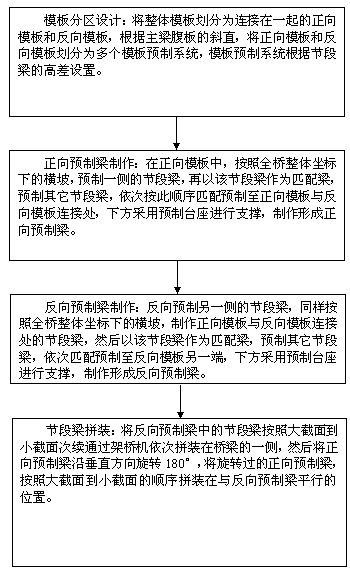

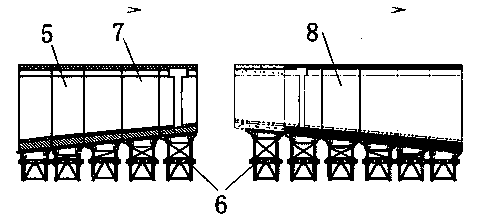

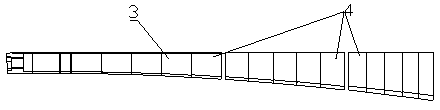

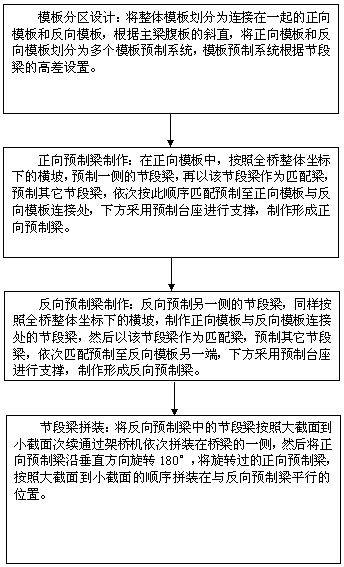

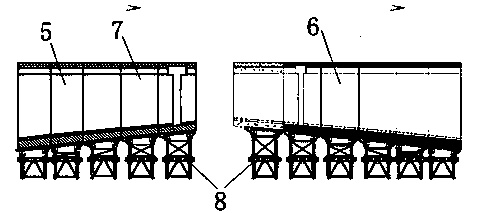

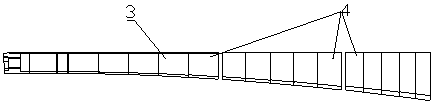

A short-line prefabricated assembly method for segmental beams with variable cross-section

ActiveCN108385504BEfficient use ofEasy mold adjustmentBridge erection/assemblyMechanical engineeringIndustrial engineering

The invention relates to a short-line prefabrication assembly method for a variable section segmental beam, belonging to the technical field of bridge construction. The short-line prefabrication assembly method includes the divisional design of a template, the manufacturing of a forward prefabricated beam, the manufacturing of a reverse prefabricated beam, the assembly of segmented beams and the like. The short-line prefabrication assembly method has the beneficial effects that a prefabricated pedestal can be fully effectively utilized, a formwork system is prefabricated by only adopting a small number of segmental beams, thus the prefabrication of all the variable section segmental beams of the main bridge can be completed, modification time of the large template caused by adjustment dueto a cross slope is avoided, the beam problems such as template idleness are avoided, the prefabrication work efficiency is greatly improved, the template adjustment is simple, convenient and accurate, and the sequence synchronization of prefabrication and on-site assembly is realized, which reduces the difficulty of construction coordination and shortens the assembly period.

Owner:CHINA FIRST HIGHWAY ENG +1

Short-line prefabrication assembly method for variable section segmental beam

ActiveCN108385504AEfficient use ofEasy mold adjustmentBridge erection/assemblyEngineeringPrefabrication

The invention relates to a short-line prefabrication assembly method for a variable section segmental beam, belonging to the technical field of bridge construction. The short-line prefabrication assembly method includes the divisional design of a template, the manufacturing of a forward prefabricated beam, the manufacturing of a reverse prefabricated beam, the assembly of segmented beams and the like. The short-line prefabrication assembly method has the beneficial effects that a prefabricated pedestal can be fully effectively utilized, a formwork system is prefabricated by only adopting a small number of segmental beams, thus the prefabrication of all the variable section segmental beams of the main bridge can be completed, modification time of the large template caused by adjustment dueto a cross slope is avoided, the beam problems such as template idleness are avoided, the prefabrication work efficiency is greatly improved, the template adjustment is simple, convenient and accurate, and the sequence synchronization of prefabrication and on-site assembly is realized, which reduces the difficulty of construction coordination and shortens the assembly period.

Owner:CHINA FIRST HIGHWAY ENG +1

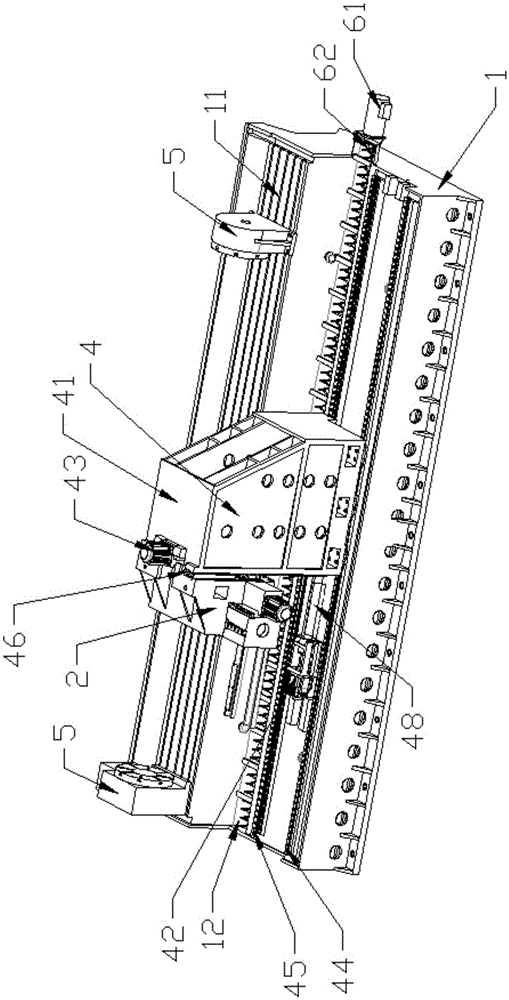

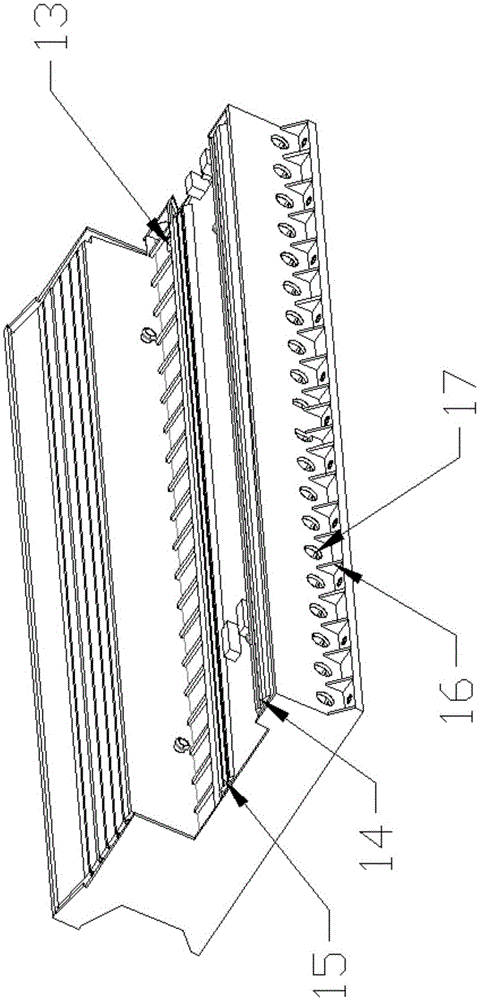

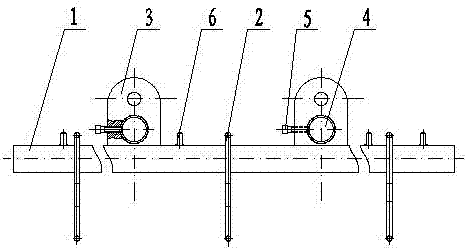

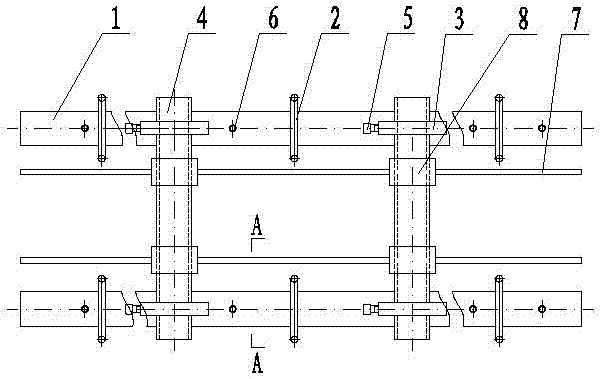

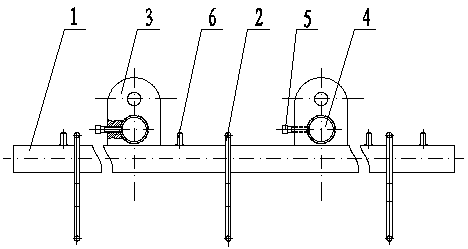

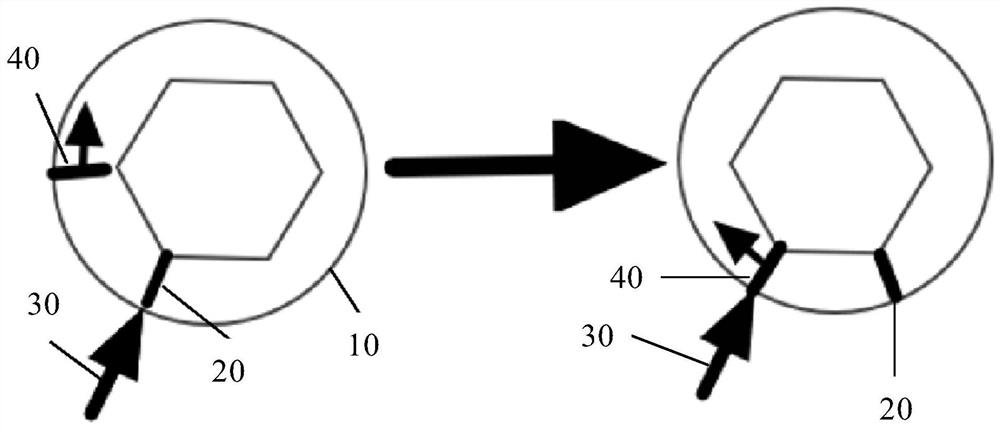

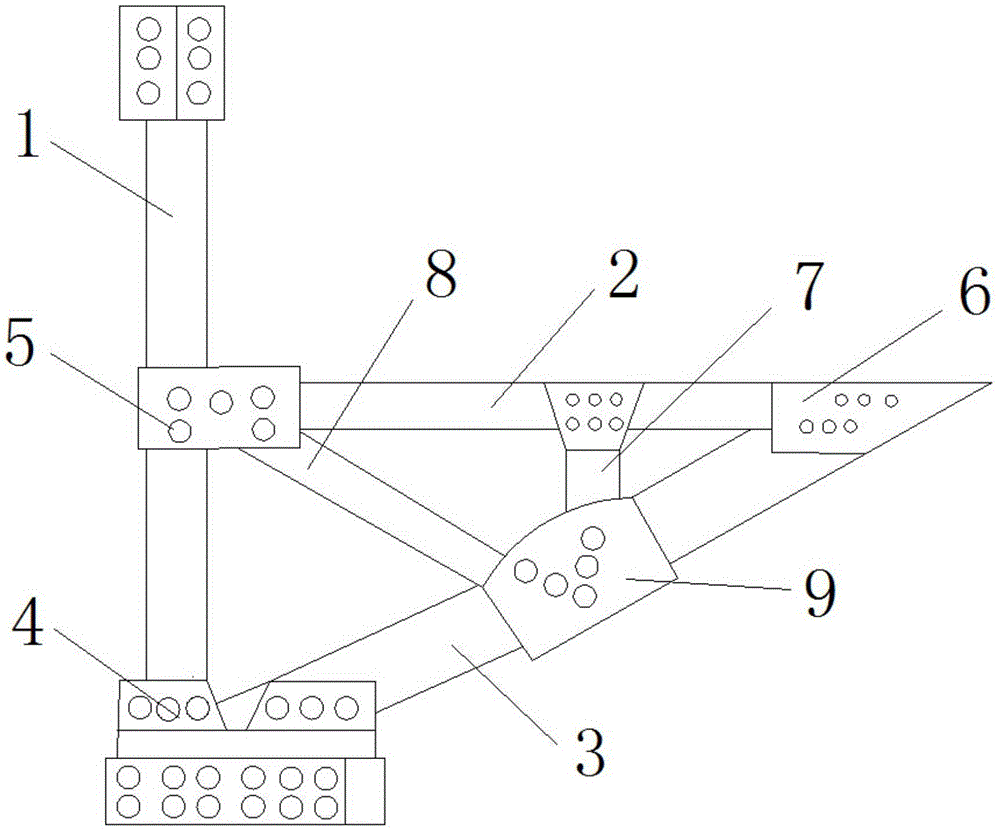

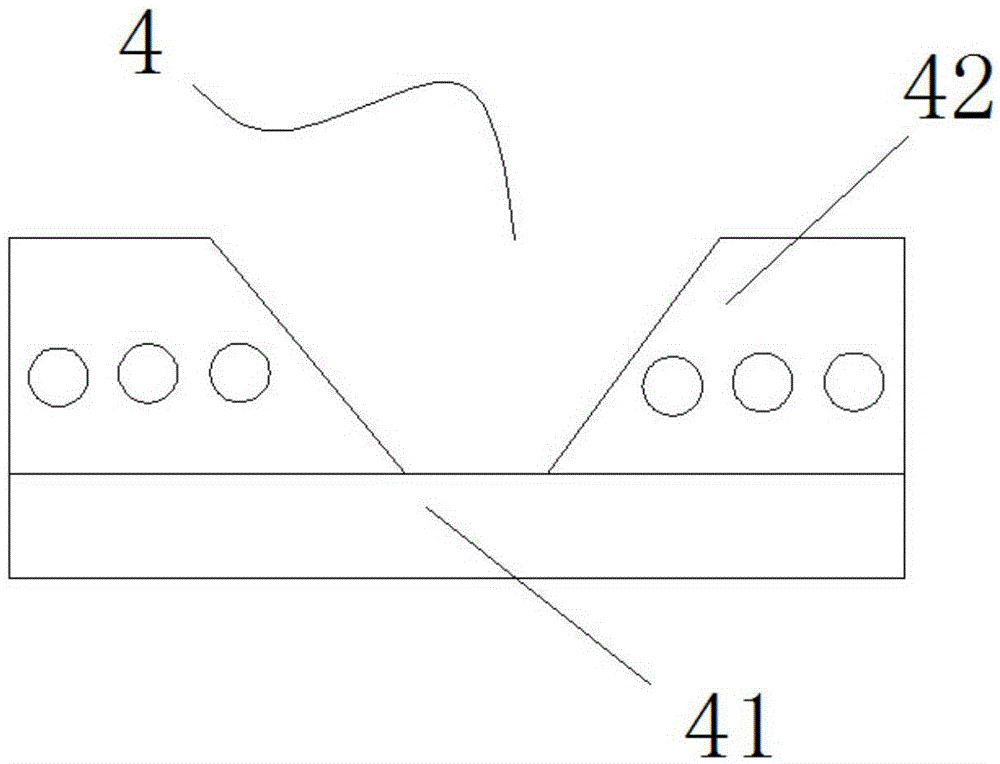

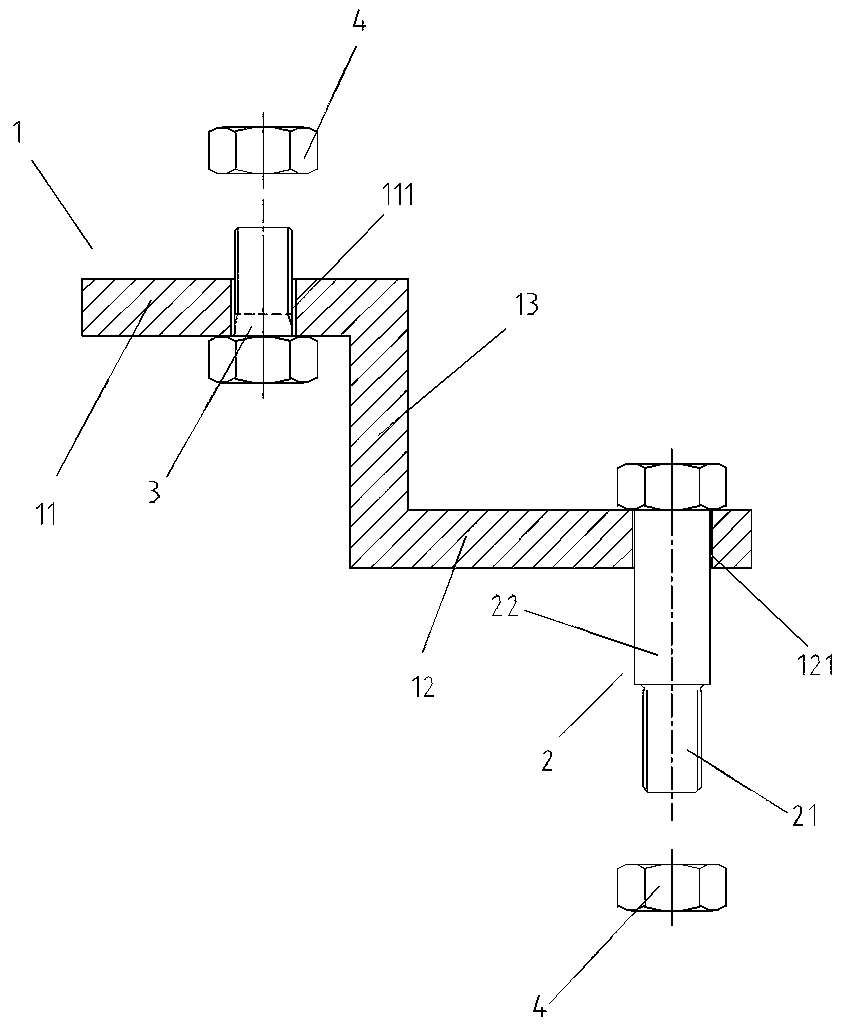

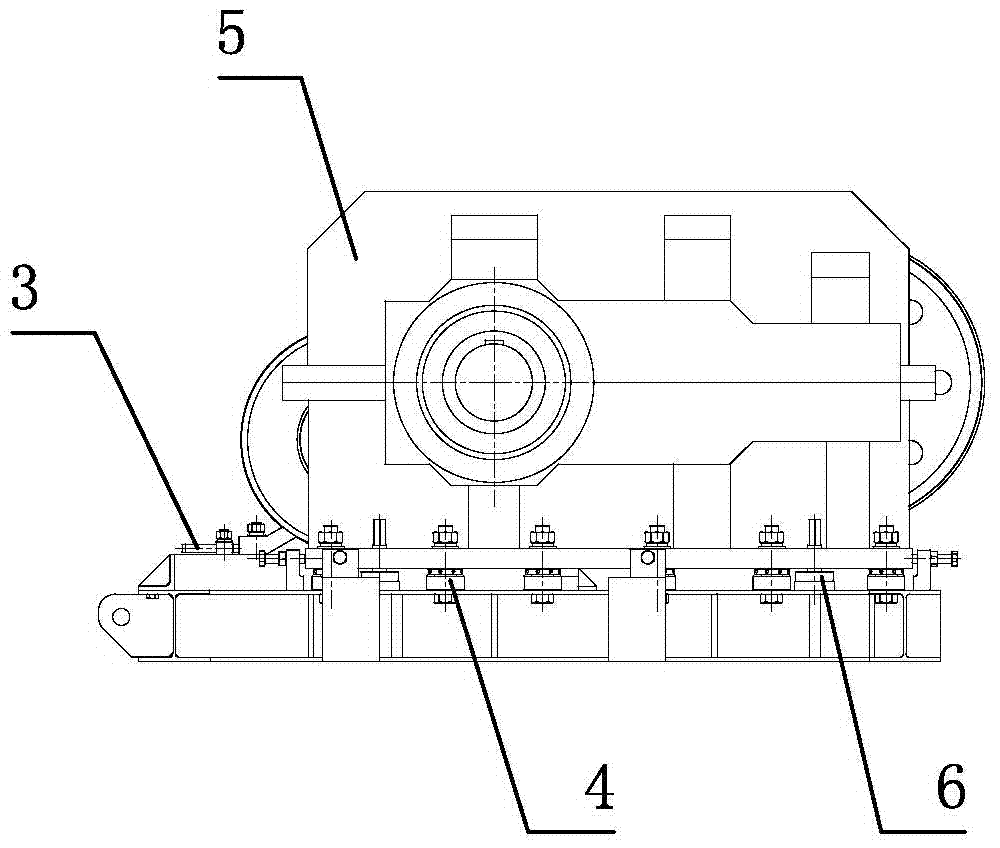

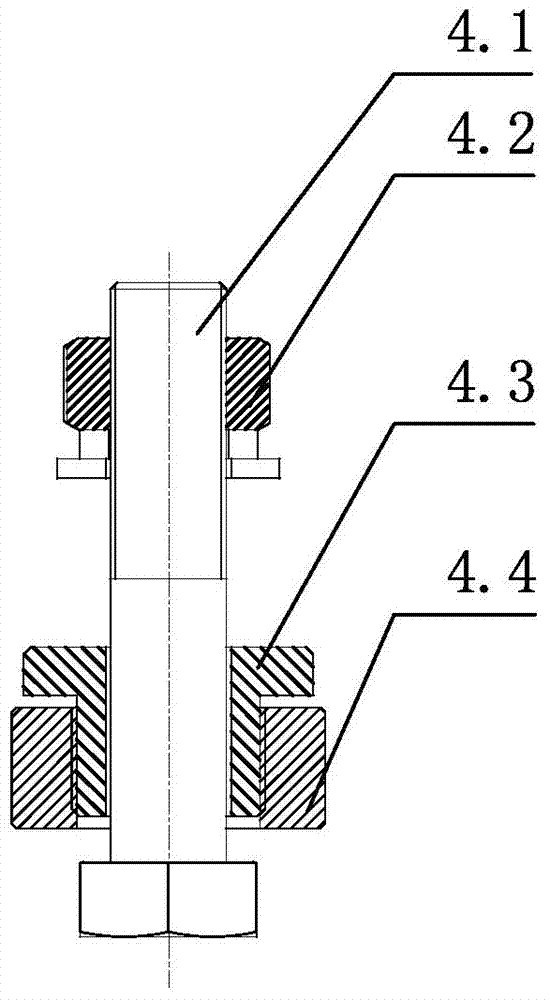

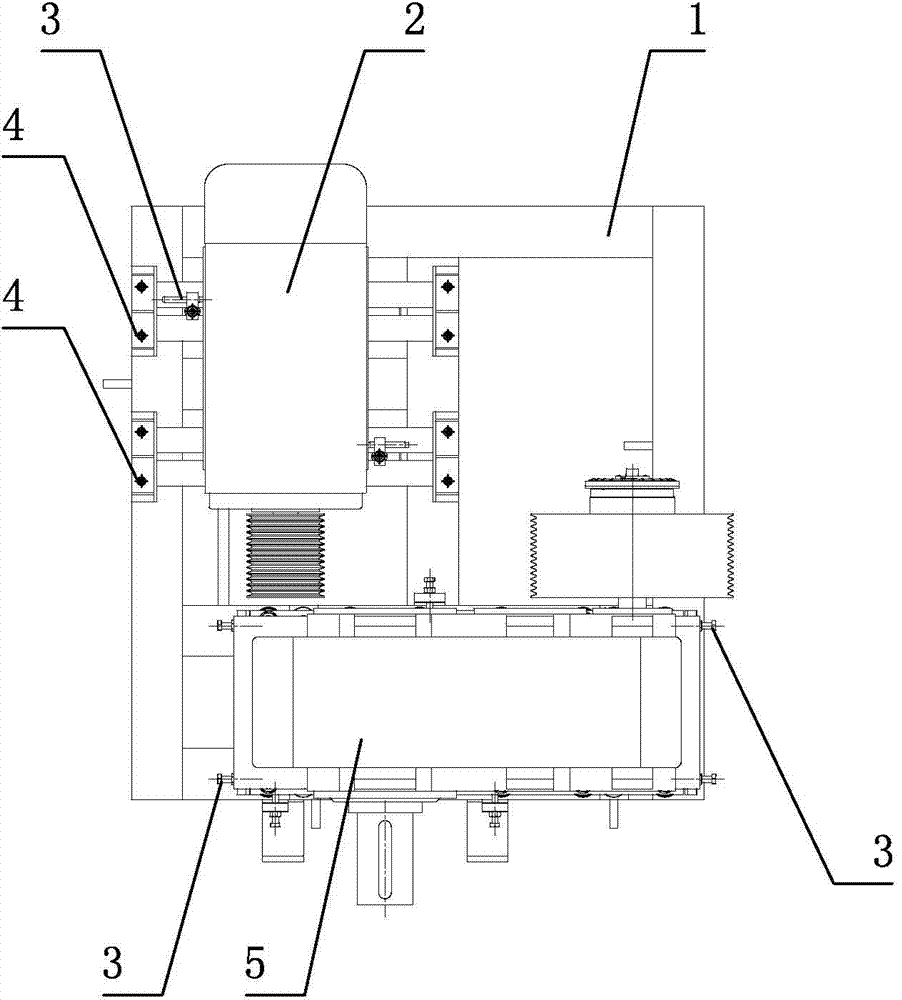

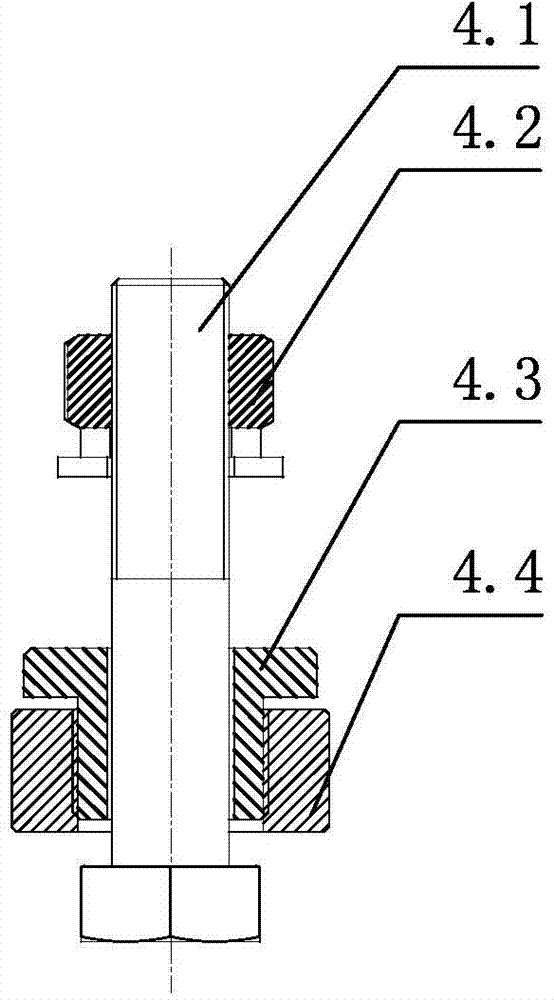

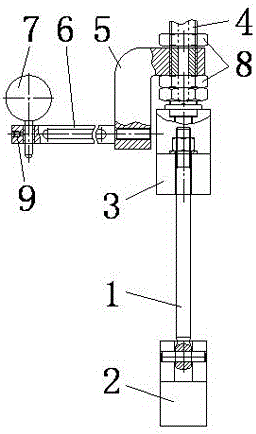

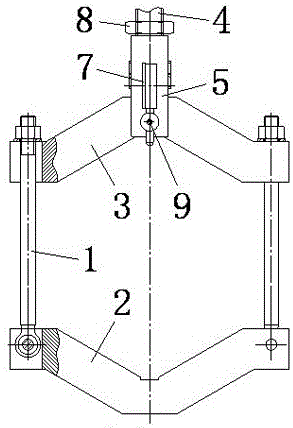

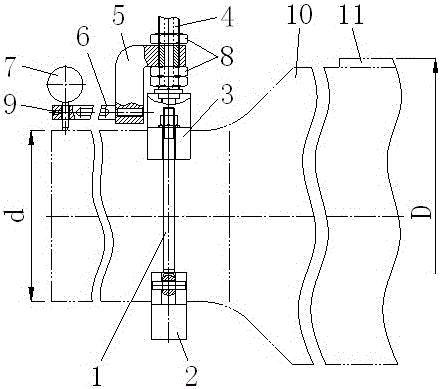

Reducer Alignment Device

ActiveCN104493958BHigh adjustment accuracyImprove regulation efficiencyCeramic shaping apparatusReducerEngineering

The invention relates to a speed reducer alignment device, in particular to a speed reducer alignment device for mounting a speed reducer on a brick extruder. The speed reducer alignment device comprises a stand, a speed reduction motor and a transmission case, wherein the speed reduction motor and the transmission case are arranged on the stand through anchor bolt components; each anchor bolt component comprises a bolt, a nut, a screw seat and a stud; a threaded hole is formed in the center of each screw seat; the studs are screwed into the threaded holes of the screw seats in a threaded fit way; through holes are formed in the centers of the studs; the bolts are arranged in the through holes in a penetration way; cap parts of the bolts are arranged at the bottoms of the screw seats; the nuts are screwed to threaded sections of the bolts. According to the speed reducer alignment device, the speed reduction motor can be rapidly aligned with the transmission case, the speed reducer alignment device is high in regulation accuracy and efficiency, and the assembling period is shortened.

Owner:GONGLI MACHINE CO LTD

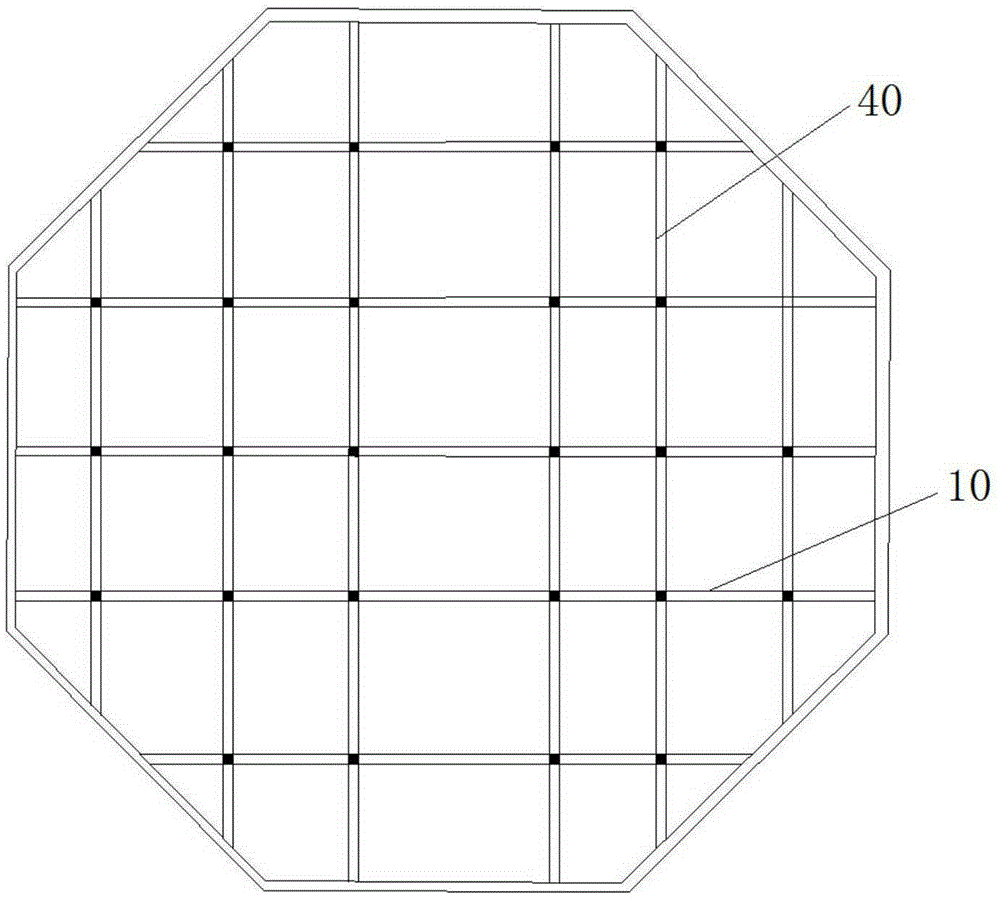

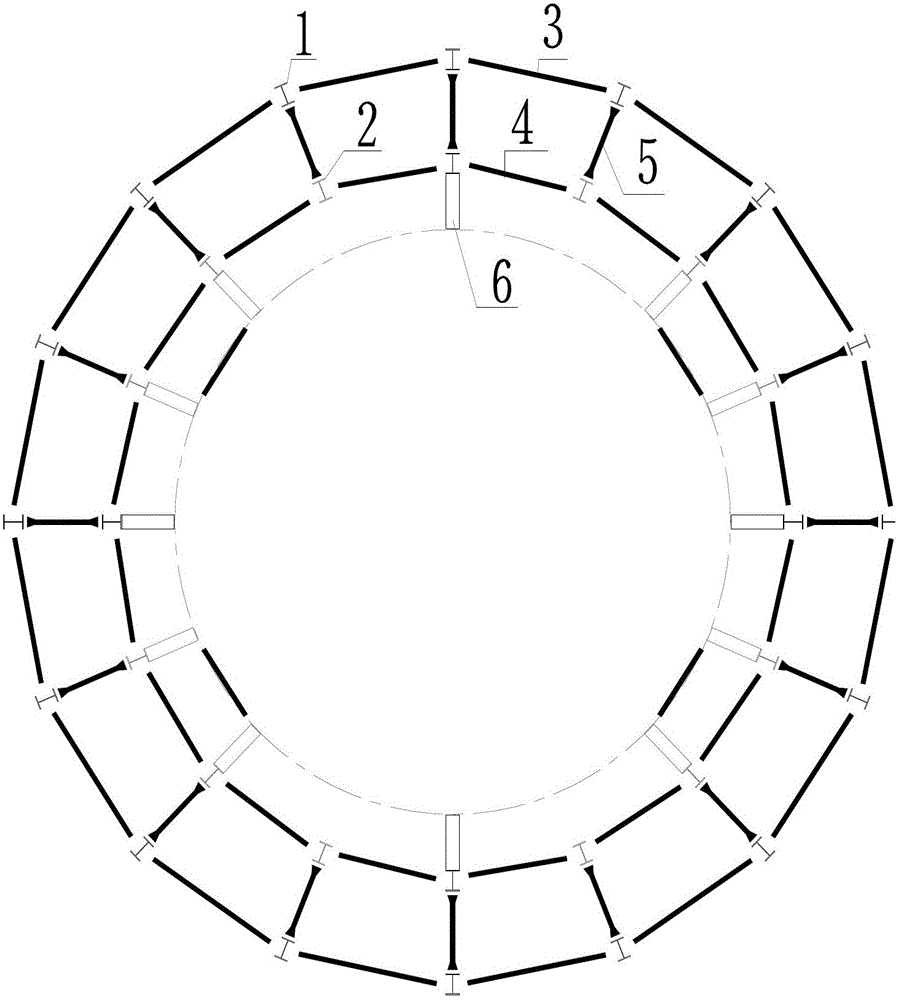

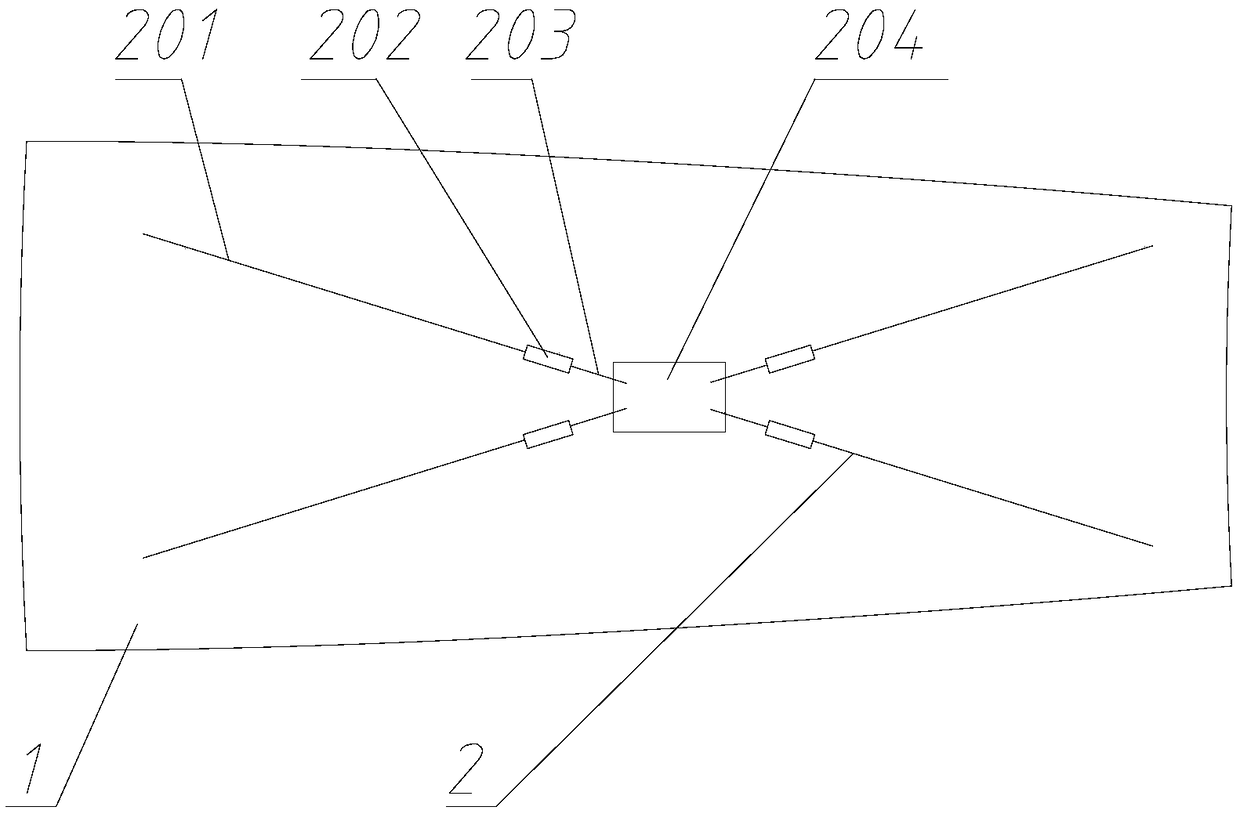

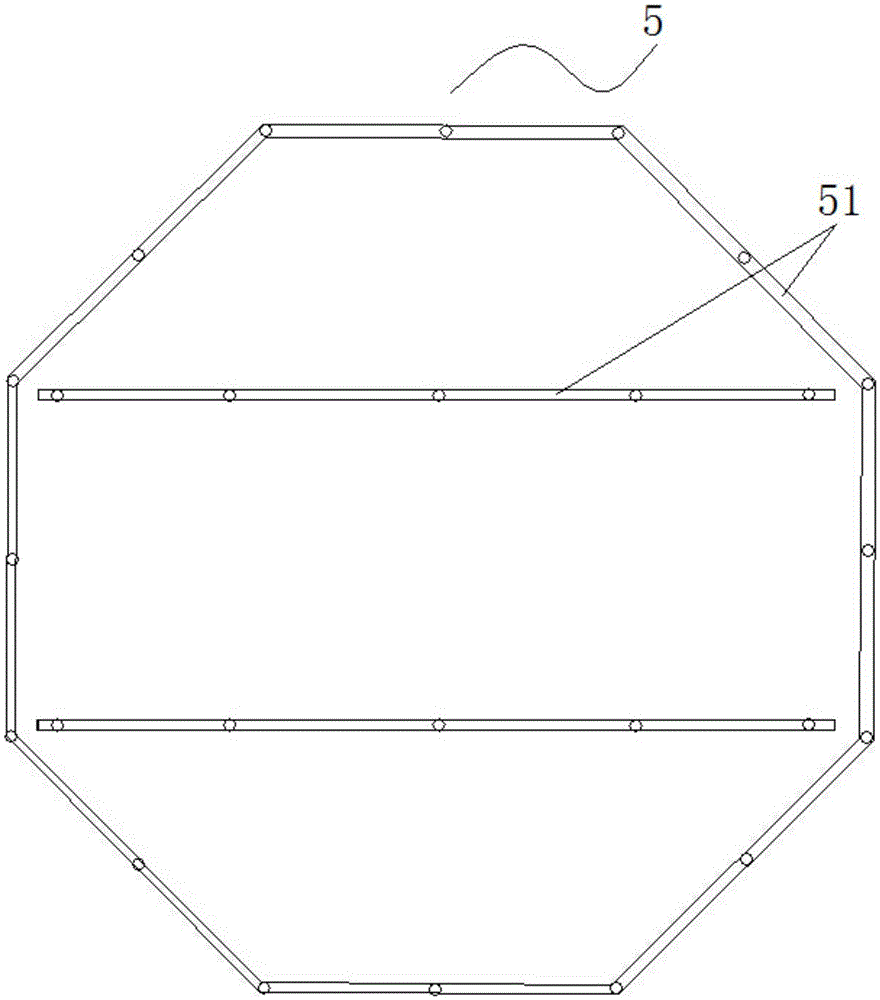

ap1000 nuclear power dome assembled tire frame

ActiveCN104141390BShorten the construction periodImprove assembly accuracyBuilding material handlingNuclear powerCorbel

The invention relates to an AP1000 nuclear power dome assembled tire frame, which includes an inner column supporting the ring beam of the dome arranged along the entire circumference, an outer column supporting one end of the dome radial beam arranged along the entire circumference, and supporting the dome radial beam Concrete foundations along the entire perimeter at the other end. The inner ring column and the outer ring column are composed of two sections along the axial direction. After the dome body is assembled, the upper half of the inner ring column and the outer ring column are dismantled, and the lower half of the inner ring column and the outer ring column are passed through the supporting cow. Leg connections; supporting corbels connect to dome modules. The invention uses less material, is easy to operate, and is connected by structural bolts, which is easy to be disassembled and transported. The tire frame structure and the lower opening of the dome have a large space, which can be used for transporting and installing internal module materials; it can effectively shorten the assembly period of the mold and the construction period of the dome, and improve the assembly accuracy of the dome.

Owner:CHINA NUCLEAR IND 24 CONSTR

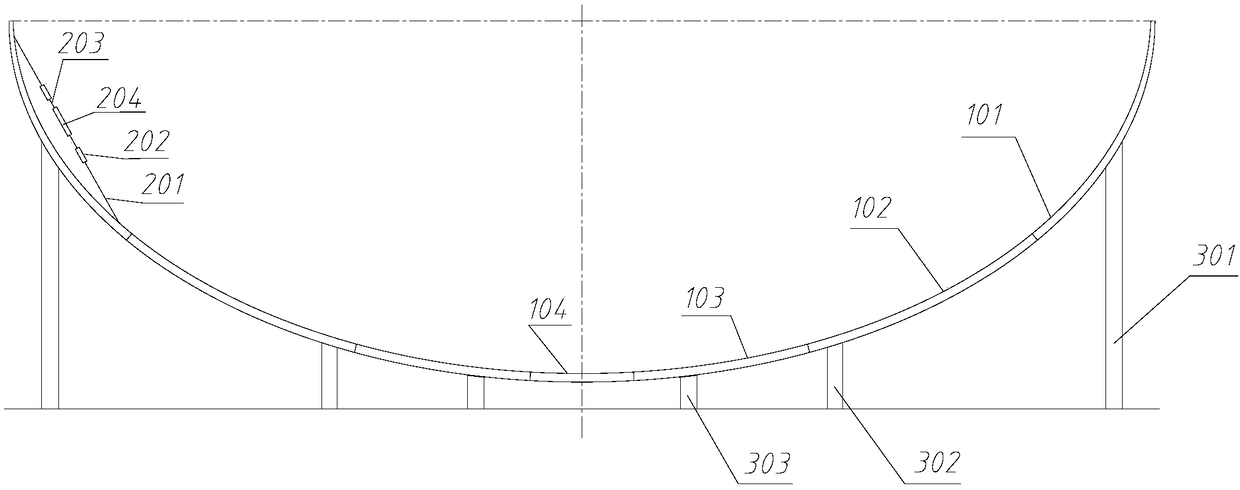

Ellipsoidal head flap single plate adjusting piece, assembling device and method thereof

InactiveCN109226991ASimple structureQuickly adjust shape and sizeWelding/cutting auxillary devicesAuxillary welding devicesSingle plateEngineering

The invention discloses an ellipsoidal head flap single plate adjusting piece, an assembling device and a method thereof. The ellipsoidal head flap single plate adjusting piece comprises a central plate arranged at the upper end of the ellipsoidal head flap and a plurality of branches extending to the edge of the ellipsoidal head flap along the central plate, wherein each branch comprises an adjusting body with adjustable length, the curved surface shape of the ellipsoidal head flap is adjusted by utilizing the length change of the adjusting body; according to the invention, the shape and sizeof the ellipsoidal head flap can be quickly adjusted, and the process complexity and investment cost in the assembling process can be reduced.

Owner:SHANDONG NUCLEAR POWER EQUIP MFG

Anti-deformation steel component single-face assembling method

ActiveCN112355501ADimensions will not changeAccuracy requirements metWelding apparatusStructural engineeringMechanical engineering

The invention provides an anti-deformation steel component single-face assembling method. The anti-deformation steel component single-face assembling method comprises the following steps that plates are prepared; pre-splicing is conducted, specifically, two side plates are spliced at the two ends of a back plate, inclined supporting plates are spliced between the back plate and the side plates, the joints of the inclined supporting plates and the side plates are welded, and a face plate is spliced at an opening to obtain a pre-spliced frame; back connection positioning is conducted, specifically, the back plates are tightly attached to each other to splice two pre-spliced frames, positioning is conducted through a clamping piece, the joints of the face plates and the side plates are welded, the face plates protrude towards the sides away from the back plates after cooling forming, and transition frames are obtained; component forming is conducted, specifically, the two transition frames are separated, and the joints of the back plates and the side plates are welded; and a transverse piece is welded, specifically, a transverse supporting piece is assembled to one side of the face plate, the joint is welded, and the front plate returns to be flat after cooling forming. According to the anti-deformation steel component single-face assembling method, in the welding and assembling process, deformation and reverse deformation actions can be achieved, it can be guaranteed that the surface of the finally-obtained steel component is straight and reliable, and machining steps and correction cost can be effectively saved.

Owner:GUANGDONG GRAND GREENBUILT TECH CO LTD

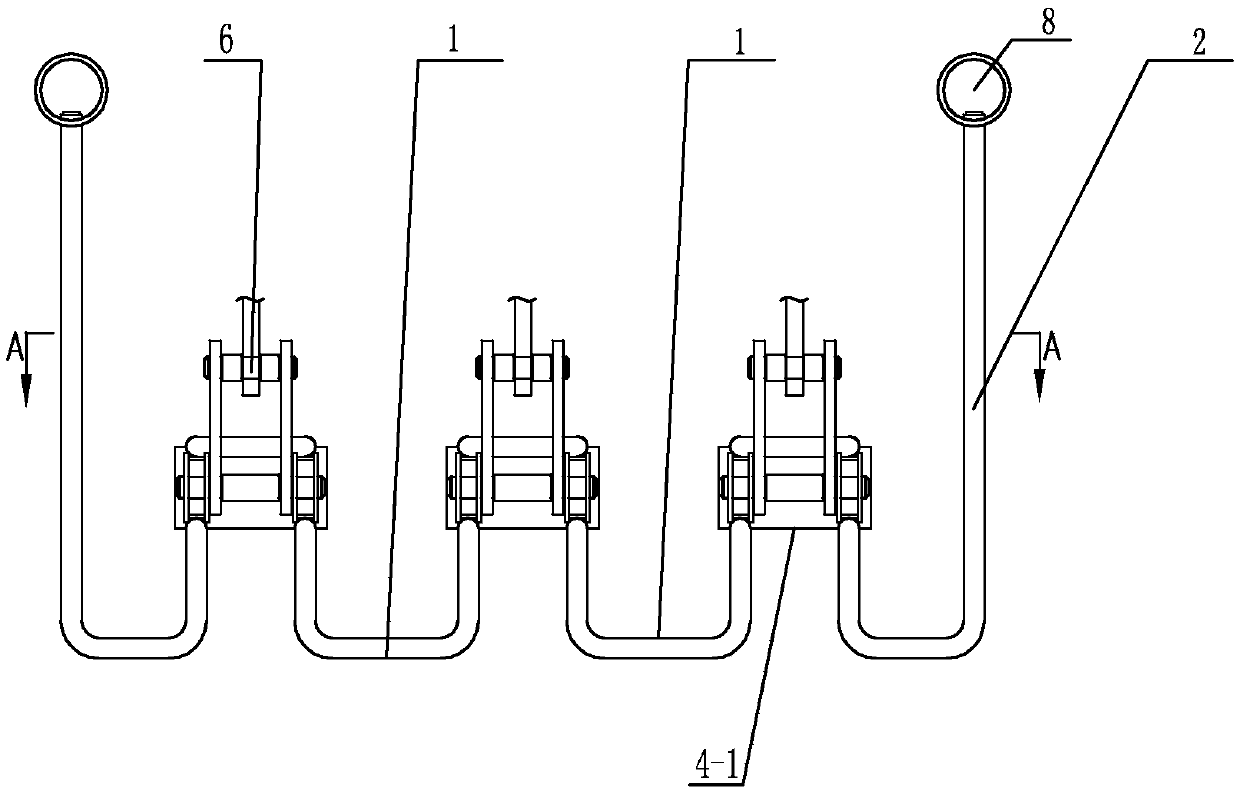

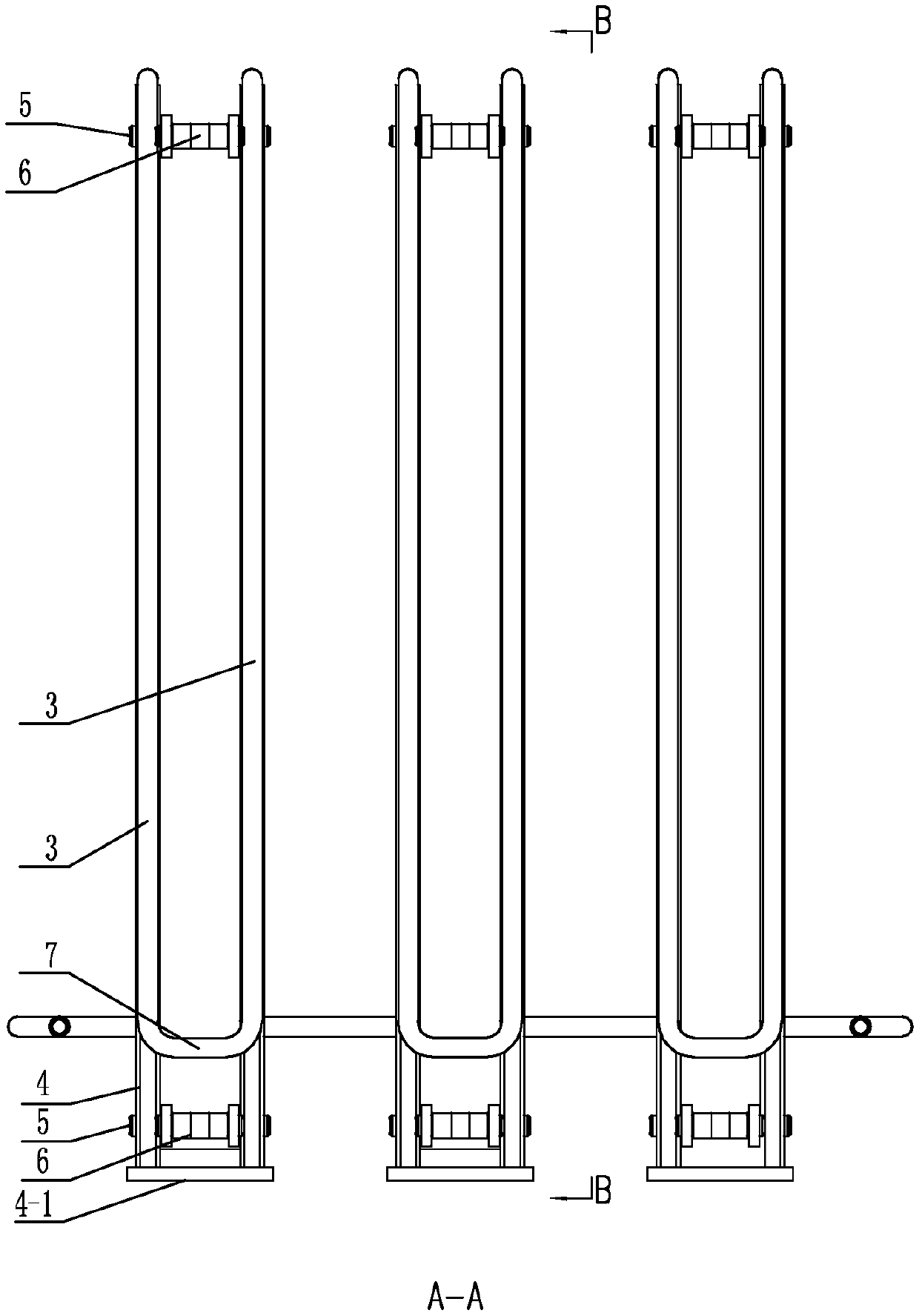

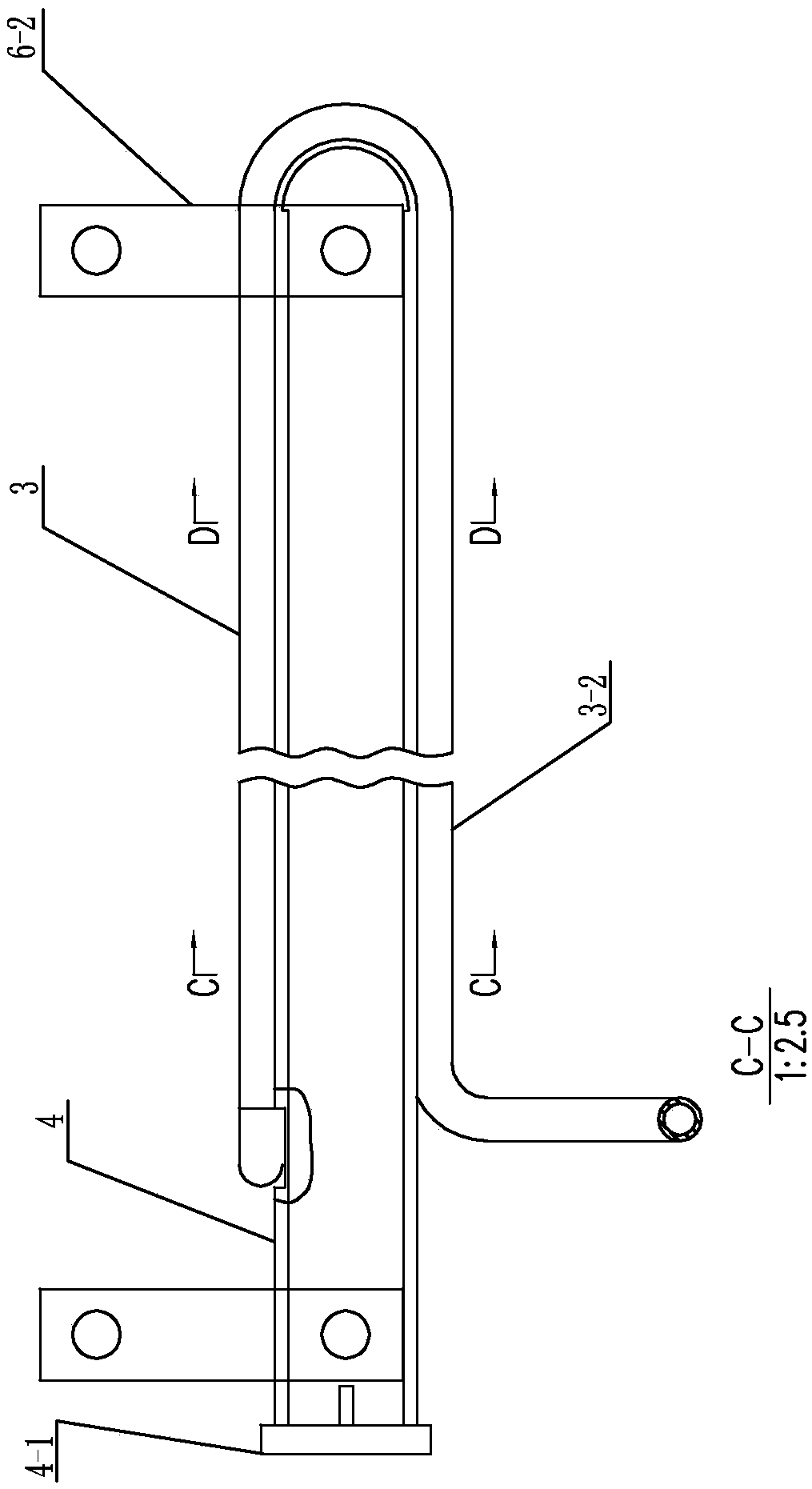

Suspension tube structure for tube screen of boiler heating surface

PendingCN109099411AReduce consumptionIncrease the heating areaFluid heatersBoiler supporting/setting arrangementsEngineering

Provided is a suspension tube structure for a tube screen of a boiler heating surface. With a suspension tube to replace a suspension beam structure to not only play the role of a suspension beam butalso increase the area of heating surface, the suspension tube structure for the tube screen of the boiler heating surface provides improvement in two different directions, wherein one is to effectively increase the area of the heating surface and improve heat exchange rate with the overall structure and the number of tube screens not changed, and the other is to increase the heating area of the suspension tube and reduces the number of the tube screens passing through the suspension tube with the heat exchange rate of the heating surface not affected to greatly reduce the difficulty of assembly. The suspension tube structure for the tube screen of the boiler heating surface comprises multiple U-shaped tubes, two hanging tubes and multiple suspension units, wherein the multiple suspensionunits are arranged side by side, adjacent suspension units are connected through one U-shaped tube, and the two suspension units located on both ends are respectively connected with the two hanging tubes. The suspension tube structure for the tube screen of the boiler heating surface is applied to the technical field of boilers.

Owner:哈尔滨哈锅锅炉容器工程有限责任公司

Speed reducer alignment device

ActiveCN104493958AHigh adjustment accuracyImprove regulation efficiencyCeramic shaping apparatusBrickElectric machinery

The invention relates to a speed reducer alignment device, in particular to a speed reducer alignment device for mounting a speed reducer on a brick extruder. The speed reducer alignment device comprises a stand, a speed reduction motor and a transmission case, wherein the speed reduction motor and the transmission case are arranged on the stand through anchor bolt components; each anchor bolt component comprises a bolt, a nut, a screw seat and a stud; a threaded hole is formed in the center of each screw seat; the studs are screwed into the threaded holes of the screw seats in a threaded fit way; through holes are formed in the centers of the studs; the bolts are arranged in the through holes in a penetration way; cap parts of the bolts are arranged at the bottoms of the screw seats; the nuts are screwed to threaded sections of the bolts. According to the speed reducer alignment device, the speed reduction motor can be rapidly aligned with the transmission case, the speed reducer alignment device is high in regulation accuracy and efficiency, and the assembling period is shortened.

Owner:GONGLI MACHINE CO LTD

Horizontal Machining Center

ActiveCN105234682BImprove stabilityEasy dischargeMachine tool componentsLarge fixed membersEngineeringMachining

Owner:JINGYIHENGZHUN TIANJIN CNC EQUIP CO LTD

Intelligent measurement construction method for positioning long arch ribs of railway

ActiveCN103821088BShorten the assembly periodEliminate high-altitude safety risksBridge erection/assemblyRailway tunnelMeasurement point

The invention provides an intelligent measurement construction method for positioning arch ribs of a long railway tunnel. During arch rib positioning, the intelligent measurement construction method includes: (1) determining a coordinate conversion parameter, (2) determining a coordinate conversion formula, (3) editing a software source code and an instrument interface source code, (4) testing software and applying if the software is qualified, (5) pasting light-reflecting pieces at four corners designed for the arch rib to serve as positioning measurement points for the arch rib, (6) performing assembling measurement for the first section of the arch rib, and (7) performing intelligent positioning measurement for the next section of the arch rib till all positioning assembling of the arch ribs are finished. The intelligent measurement construction method is applied to 180 meters of continuous beam arch rib assembling in the Nanfei river bridge of the HeFu railway, safety risk during constructional measurement is reduced, arch rib positioning efficiency is improved greatly, and cost is saved.

Owner:THE FOURTH ENG CO LTD OF CTCE GRP

Large-section inclined shaft open channel segment construction method and high-strength combined form board thereof

PendingCN111577330AEnsure stabilityClosed in timeUnderground chambersDrainageArchitectural engineeringRebar

The invention belongs to the technical field of inclined shaft construction, and discloses a large-section inclined shaft open channel segment construction method and a high-strength combined form board thereof. The combined form board comprise an inner form board and an outer form board mounted on the outer side of the inner form board, arc binding steel reinforcing ribs are mounted between the inner form board and the outer form board, the inner form board is formed through splicing of multiple combined form board bodies, each combined form board body is composed of four supporting legs andnine combined arch plates, the outer form board comprises a steel plate strip and a 9mm plate, the steel plate strip is fixedly connected to the inner form board through the 9mm plate and a lengthening bolt, due to use of the high-strength whole form board, in the construction application, the economic benefits are extremely obvious, the conditions that a traditional splicing form board in vertical self-closed framework is slow in concrete pouring speed, the surface soil segment is slow in construction proceed, and staggered forming is poor can be solved, the form board deforming capacity is enhanced, the service life of the form board is prolonged, the construction safety and stability can be improved, and the construction efficiency and the construction proceed can be improved.

Owner:PINGMEI SHENMA CONSTR ENG GROUP

Top layer supporting system for helipad

InactiveCN106836029AEfficient assemblyEasy to assembleHelicopter landing platformSupporting systemEngineering

The invention discloses a support system for the top floor of a helipad, which comprises a plurality of sets of trusses arranged in parallel and a connecting frame vertically arranged between two adjacent trusses; the trusses and the connecting frames are connected by a reinforcing device; An oblique connection frame is also connected between the two oblique pairs of reinforcing devices. The helipad top support system of the present invention is assembled with reinforcement devices, and the trusses, connecting frames and oblique connecting frames form a triangular structure, which not only improves the safety and stability of the structure, avoids corrosion and cracks caused by welding and assembly stress, but also is fast and efficient , shorten the assembly period. In addition, the setting of the drainage unit can timely drain the accumulated water on the apron deck and reduce the load bearing of the apron deck in rainy days. On the premise of ensuring a safe and reliable structure, the helipad top support system of the present invention is simple and quick to assemble, and has strong practicality and market promotion value.

Owner:台澳铝业(台山)有限公司

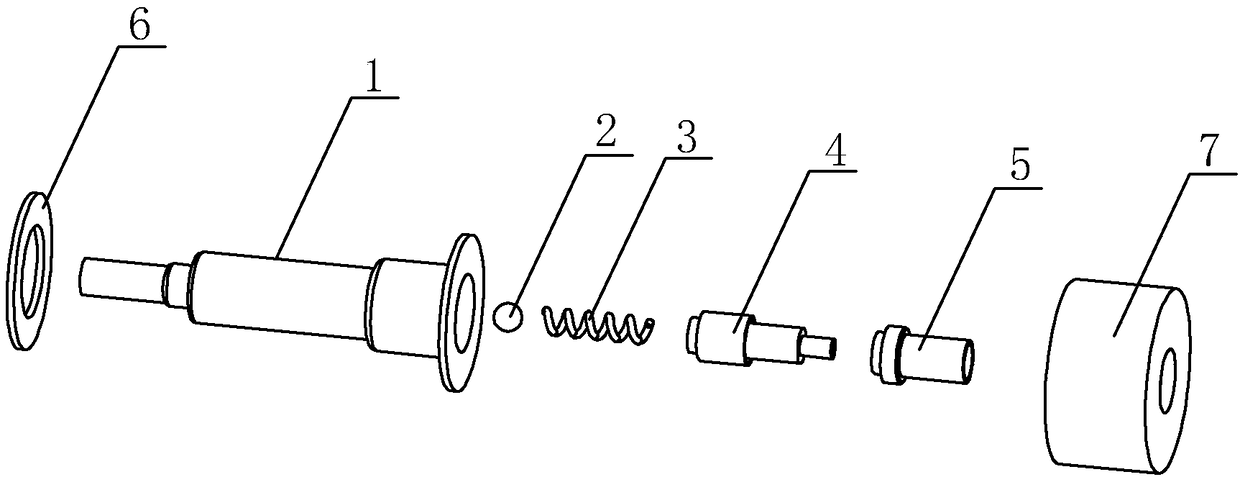

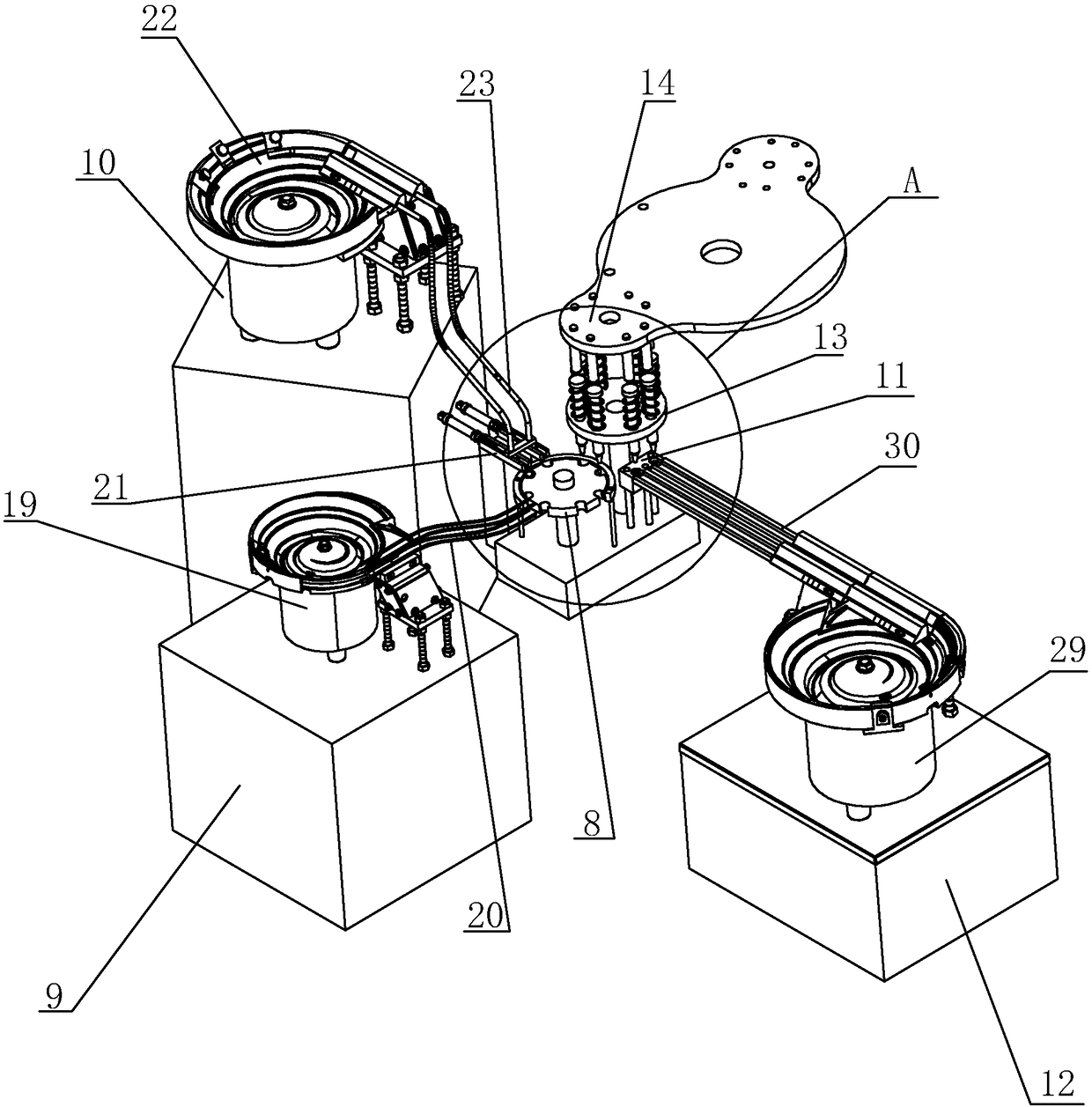

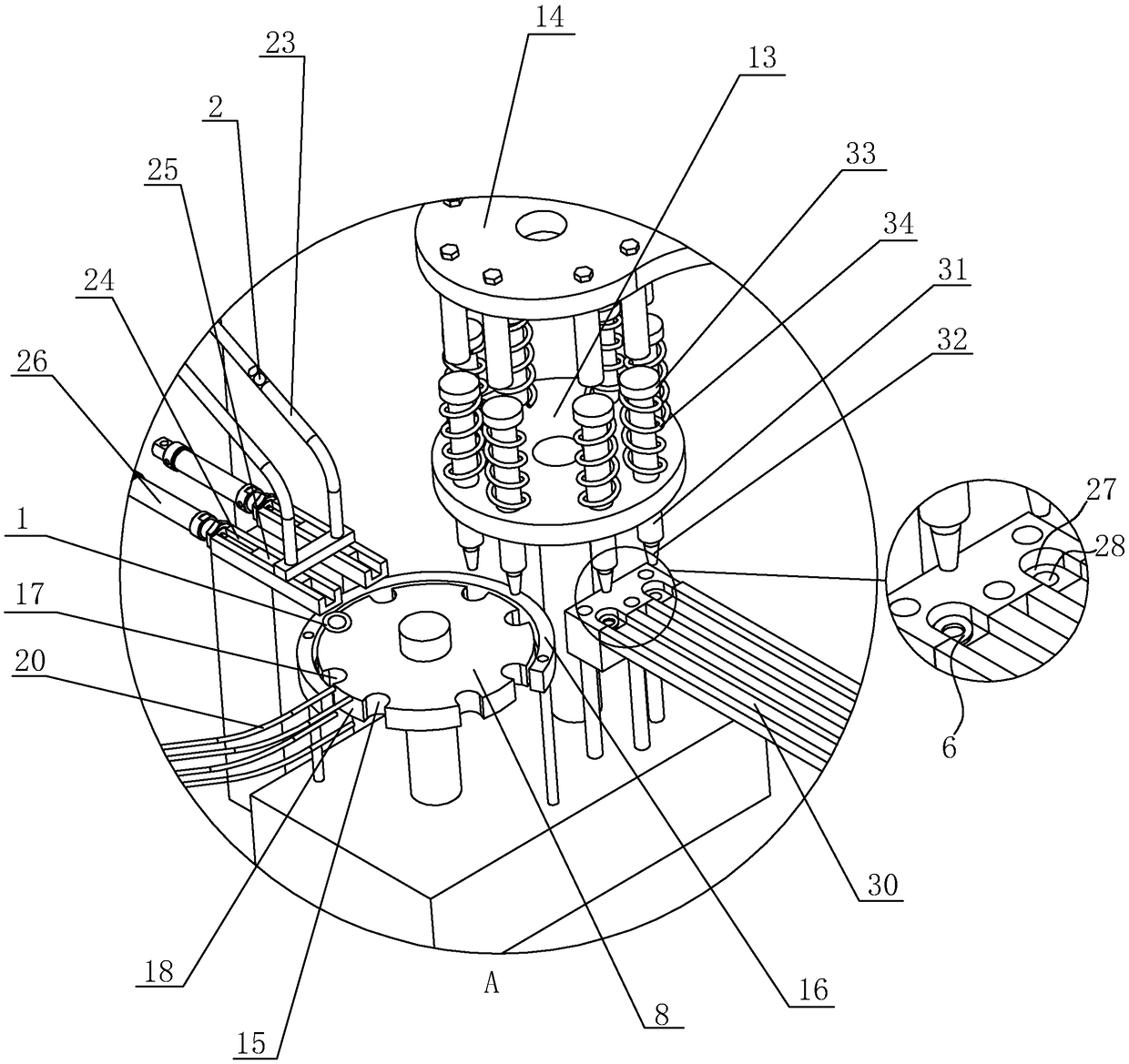

A lotion pump automatic assembly machine

InactiveCN106743378BShorten the assembly periodImprove assembly efficiencyAssembly machinesMetal working apparatusEngineeringLotion

Owner:余姚市翔盛塑业有限公司

A measuring tool and measuring method for measuring the diameter of the circumscribed circle of the revolving circle of the reamer roller

ActiveCN103776343BReduce labor intensityLarge measuring rangeMechanical diameter measurementsDesign standardEngineering

The invention discloses a measuring tool and a measuring method for measuring the diameter of the circumscribed circle of the revolving wheel of an eye marker. The measuring tool includes a lower V-shaped iron (2) and an upper V-shaped iron (3) connected by bolts (1); a support rod (4) is provided in the center of the top surface of the upper V-shaped iron, and the support rod is provided with a A measuring seat (5) for axial movement on the rod, at least two positioning nuts (8) are arranged on the supporting rod; a measuring rod (6) is arranged on the measuring seat, and a measuring instrument (7) is arranged on the measuring rod. The invention uses a set of measuring tools to realize the measurement of multiple specifications of series products, replacing hundreds of existing ring gauges. The measurement benchmark coincides with the design benchmark to ensure the coaxiality between the circumcircle of the roller's revolution and the main body, and the measurement accuracy can reach 0.05 mm, which improves the reliability of product quality. The measurement process of the three-roller eye marker in the present invention is simple, accurate, labor-saving and time-saving, and is also applicable to the measurement of the larger diameter of the circumscribed circle of revolution of other planetary rollers.

Owner:GUIZHOU GAOFENG GASOLINEEUM MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com