Suspension tube structure for tube screen of boiler heating surface

A heating surface tube and suspension tube technology, which is applied in the field of boilers, can solve the problems of high precision of tube panel bending, limited welding space, and difficult assembly, etc., so as to save raw materials, reduce assembly difficulty, and reduce total weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

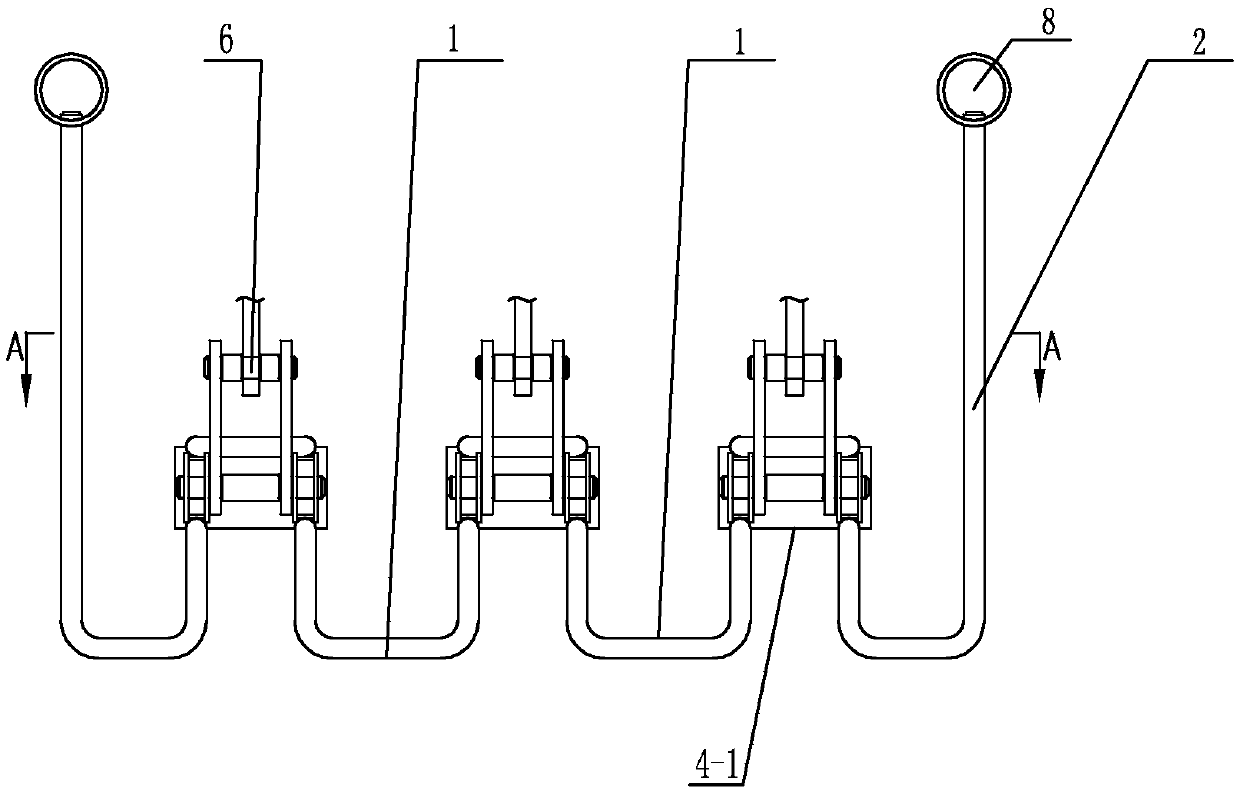

[0026] Specific implementation mode one: combine figure 1 Describe this embodiment, a boiler heating surface tube panel suspension tube structure in this embodiment includes a plurality of U-shaped tubes 1, two suspension tubes 2 and a plurality of suspension units, and a plurality of the suspension units are arranged side by side Two adjacent suspension units are connected by a U-shaped tube 1 , and the two suspension units located at both ends are respectively connected with two suspension tubes 2 . The number of suspension units can be increased or decreased according to the number of longitudinal tube panels.

specific Embodiment approach 2

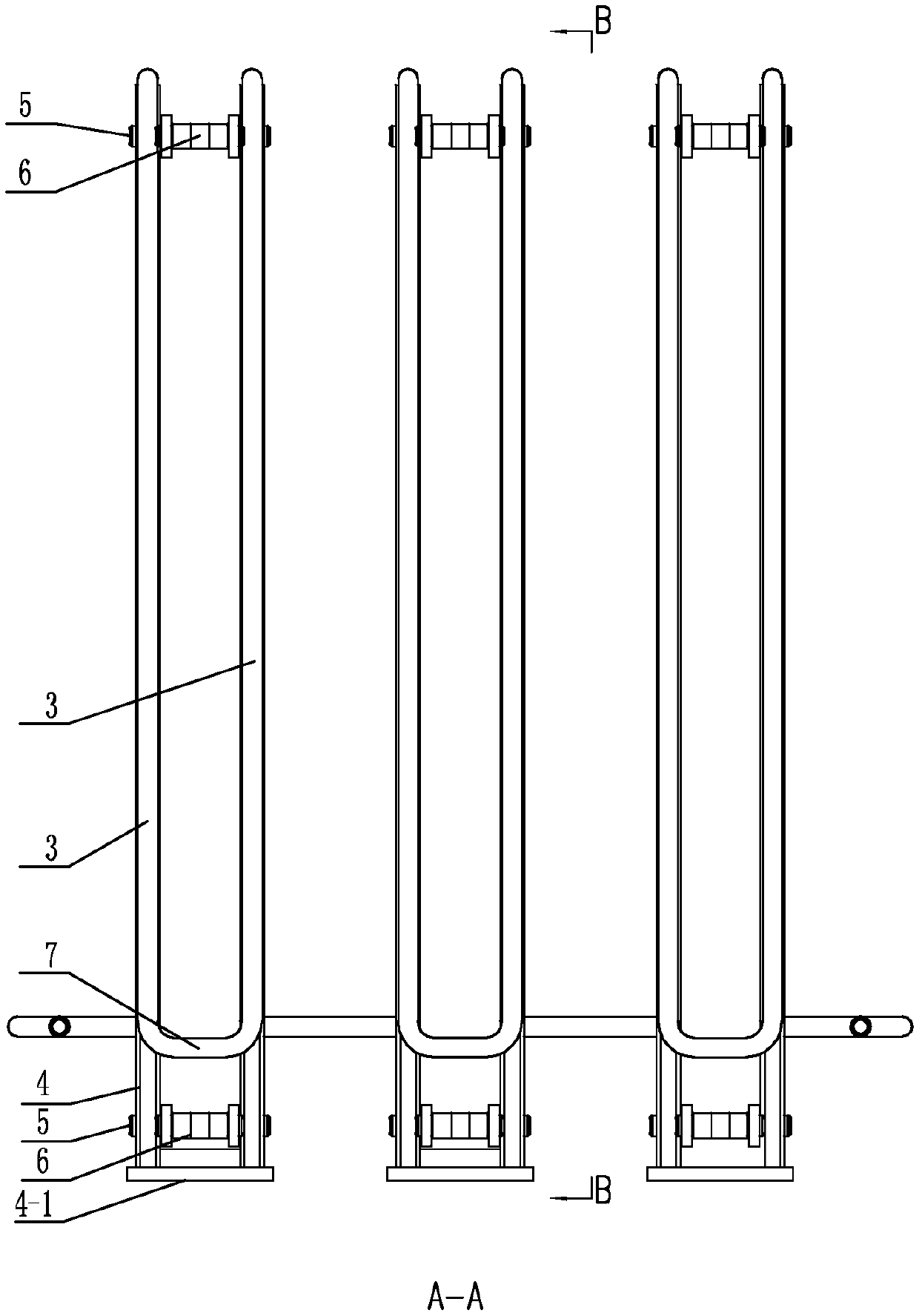

[0027] Specific implementation mode two: combination Figure 2 to Figure 3 Describe this embodiment, a boiler heating surface tube panel suspension pipe structure of this embodiment, each of the suspension units includes two U-shaped suspension pipes 3, two suspension pipe fixing devices 4, two pin shafts 5, The two hanging components 6 and the elbow 7, the two U-shaped hanging pipes 3 are respectively set on the two hanging pipe fixing devices 4, and the ends of the two U-shaped hanging pipes 3 located on the upper surface of the hanging pipe fixing device 4 pass through The elbow 7 is connected, and two pin shafts 5 are arranged side by side in parallel at the front and rear ends of the hanging pipe fixing device, and the two ends of each pin shaft 5 are connected with two hanging pipe fixing devices 4, and the hanging assembly 6 and the pin shaft 5 the middle connection. Other compositions and connections are the same as in the first embodiment.

[0028] The U-shaped hang...

specific Embodiment approach 3

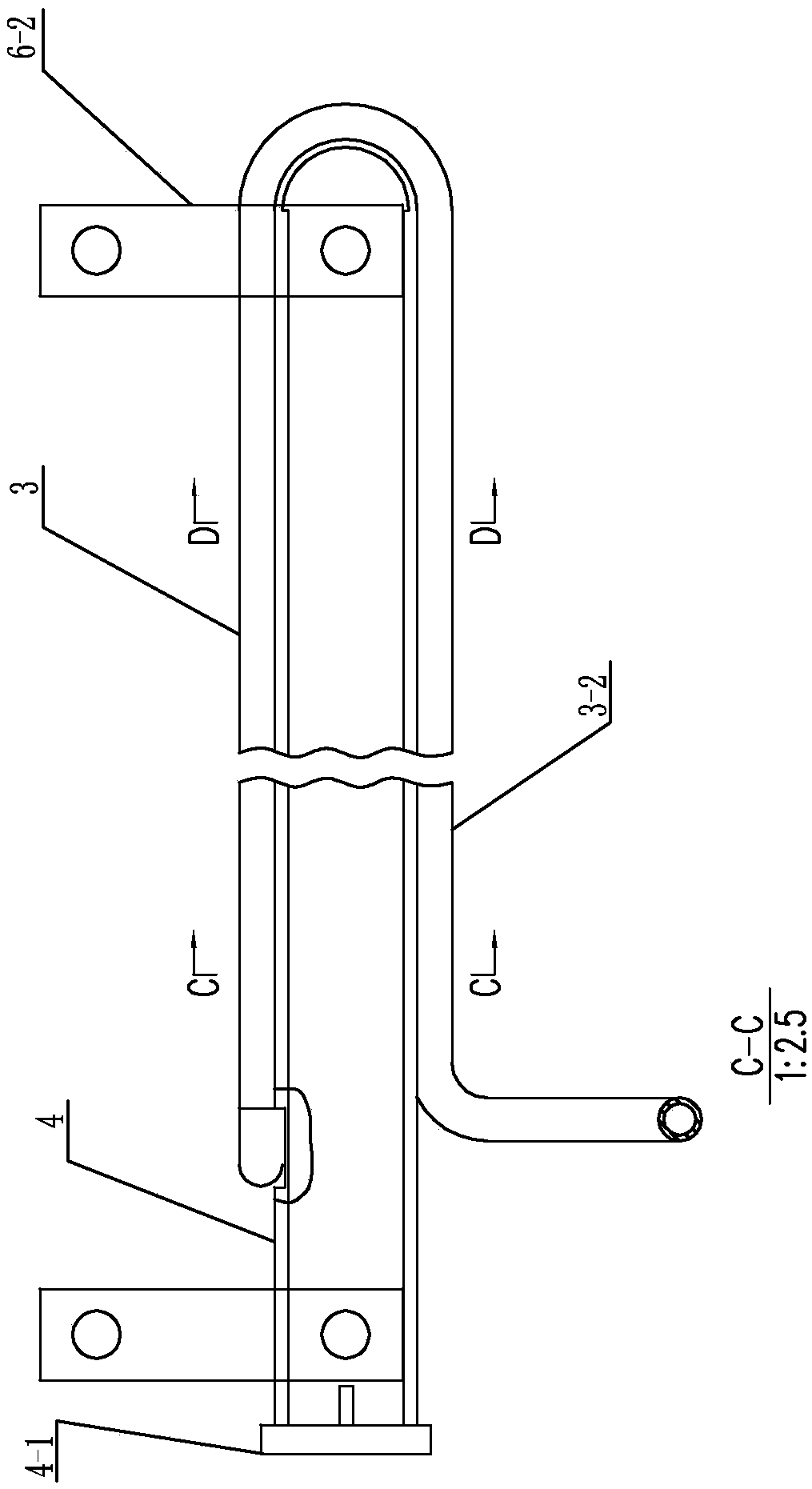

[0029] Specific implementation mode three: combination Figure 4 Describe the present embodiment, the hanging pipe fixing device 4 of the boiler heating surface tube panel hanging pipe structure of the present embodiment is a horizontal plate composed of an upper plate 4-1, a lower plate 4-2 and two side plates 4-3. A square tube with a rectangular cross section. This structure is used for fixing U-shaped hanging pipe 3 . Other compositions and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com