Nuclear turbine high-pressure outer cylinder split assembling method

A technology of high-pressure external cylinder and assembly method, which is applied in the direction of mechanical equipment, engine components, machines/engines, etc., and can solve the problems of unit steam leakage, high assembly quality requirements, and insufficient assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

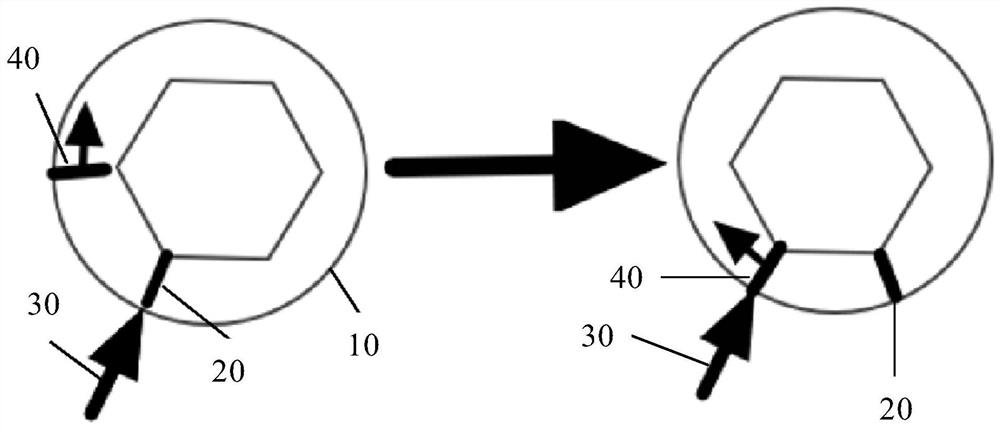

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

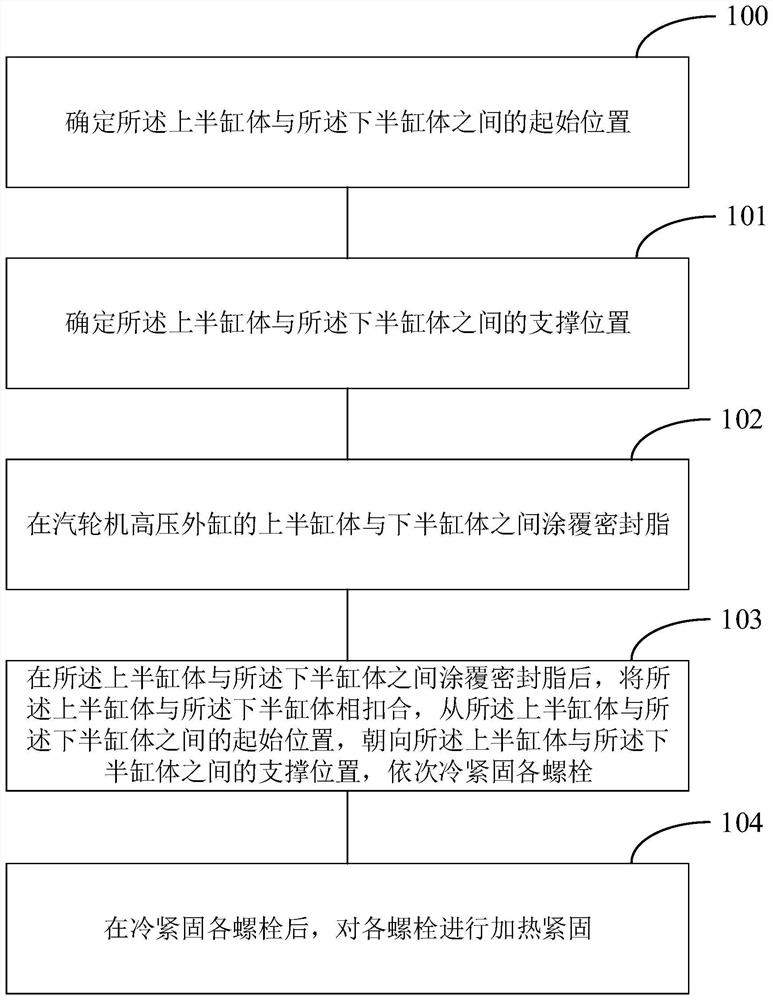

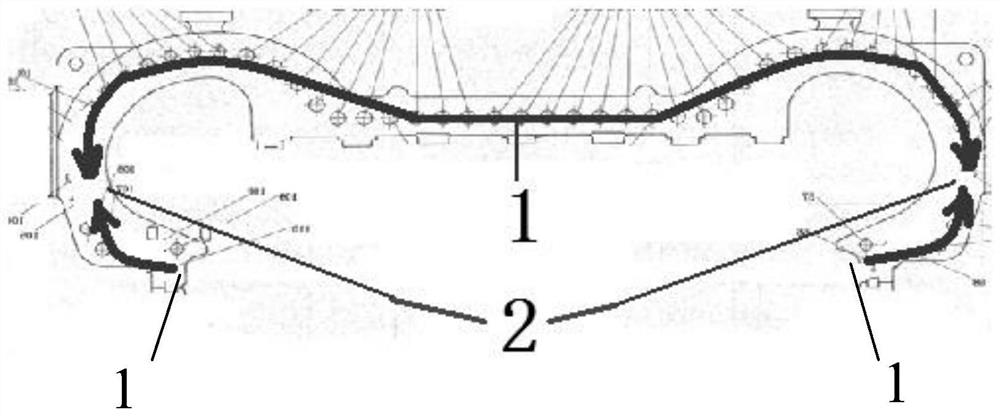

[0029] figure 1 It is a flow chart of a method for assembling facets in a high-pressure outer cylinder of a nuclear power steam turbine according to an exemplary embodiment. Such as figure 1 As shown, the method may include:

[0030] Step 100, determine the initial position between the upper half cylinder and the lower half cylinder, the initial position is that the vertical arc between the upper half cylinder and the lower half cylinder meets the judgment condition s position;

[0031] As an example of this embodiment, in step 100, the sag between the upper half cylinder and the lower half cylinder may be greater than the first sag threshold ( example of the judgment condition) as the starting position; it is also possible to arrange the first N (N is a natural number, another example of the judgment condition) positions of the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com