ap1000 nuclear power dome assembled tire frame

A technology of dome and nuclear power, applied in construction, building structure, processing of building materials, etc., can solve the problems of long construction time, large space occupation, complex design structure, etc., achieve large construction space, easy operation, and improve assembly accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0018] Tire frame installation process: tire frame foundation installation and leveling—measurement and setting out on the foundation—column unit installation—column support connection.

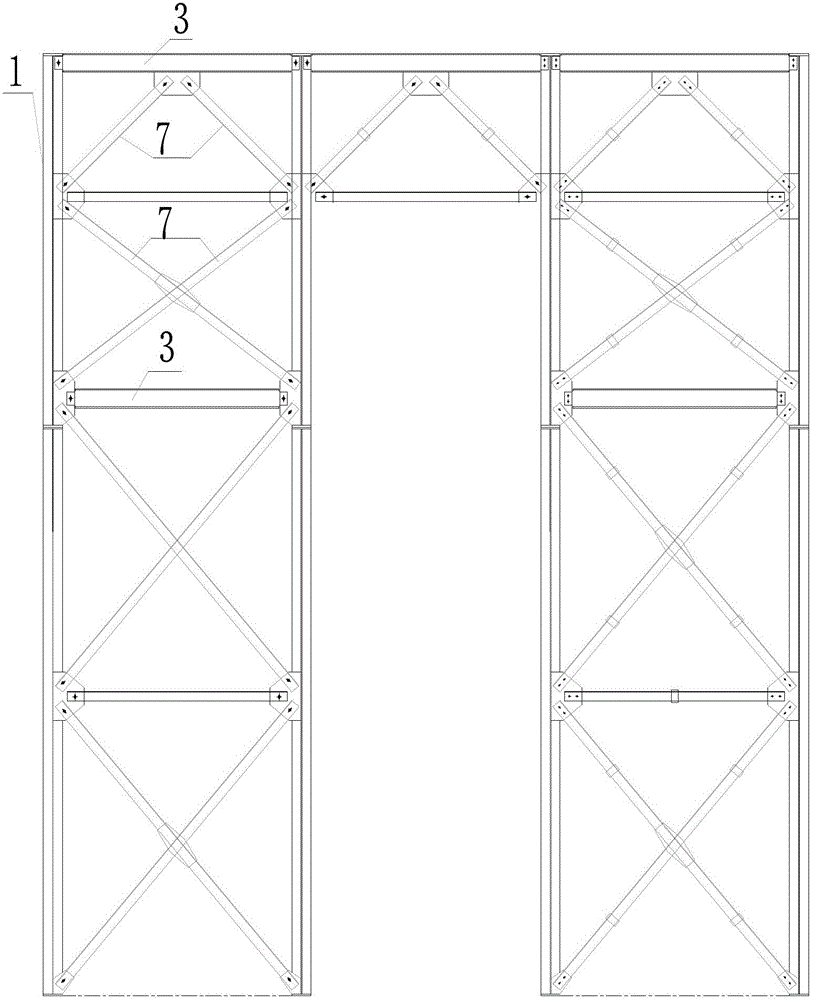

[0019] Outer ring unit implementation mode: the outer ring columns 1 arranged along the entire circumference are connected with the outer ring beam steel 3 and diagonal braces 7 by bolts to form a stable truss structure, such as figure 2 shown.

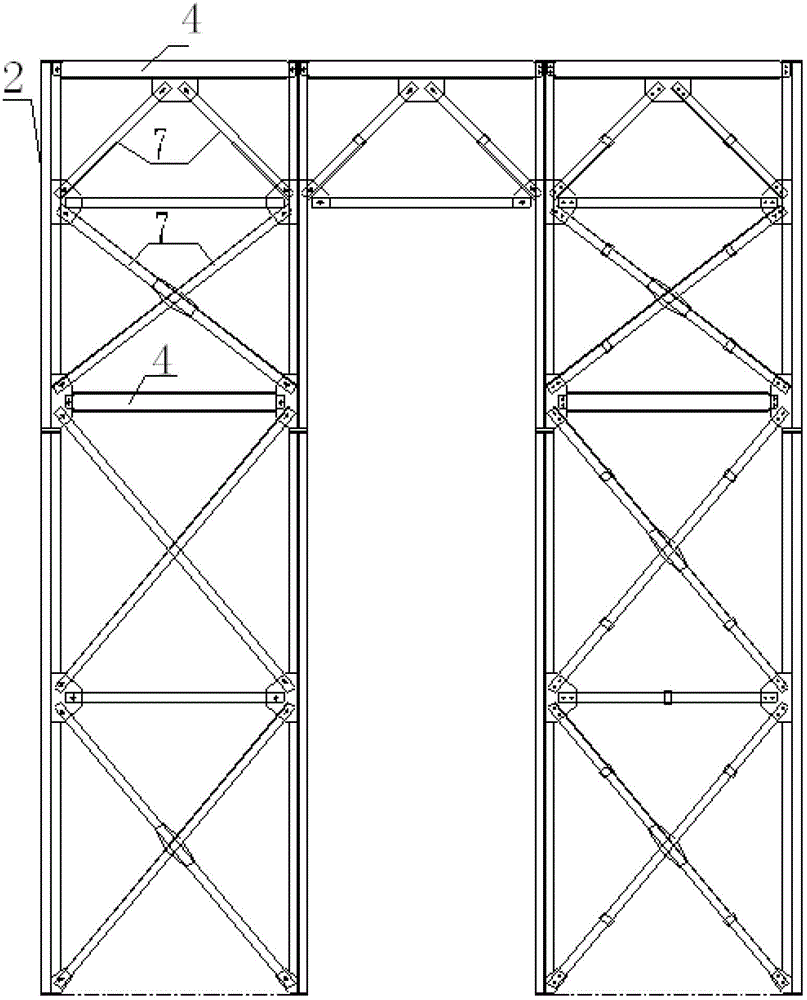

[0020] Inner ring unit implementation mode: the inner ring columns 2 arranged along the entire circumference are connected with the inner ring beam steel 4 and diagonal braces 7 by bolts to form a stable truss structure, such as image 3 shown.

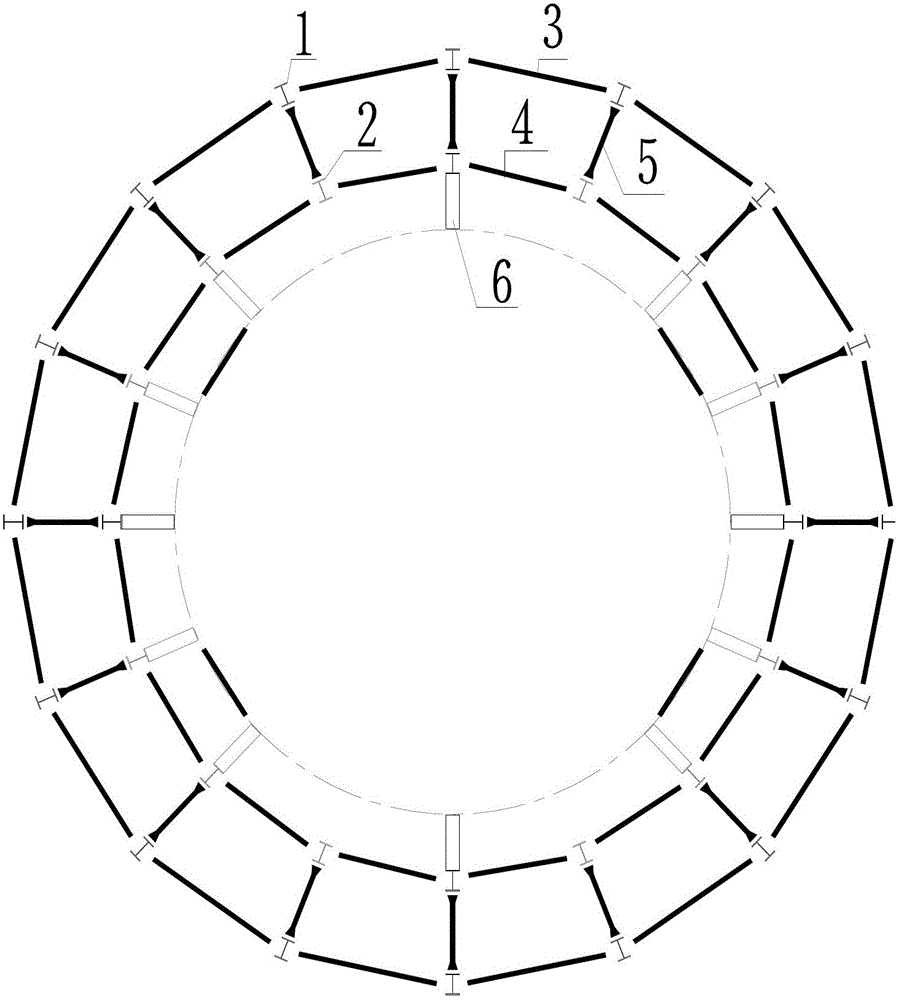

[0021] Implementation mode between the inner and outer rings: The corresponding positions of the outer ring column 1 and the inner ring column 2 are connected by bolts wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com