Anti-deformation steel component single-face assembling method

An assembly method and technology of steel components, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to meet precision requirements, shrinkage, shrinkage of steel plate size, etc., to save processing steps and correction costs, assembly production efficiency High, flat and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

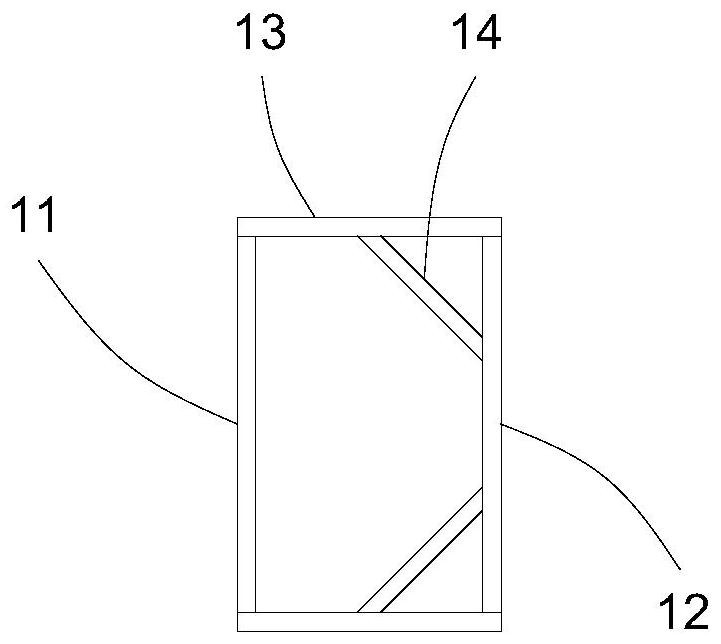

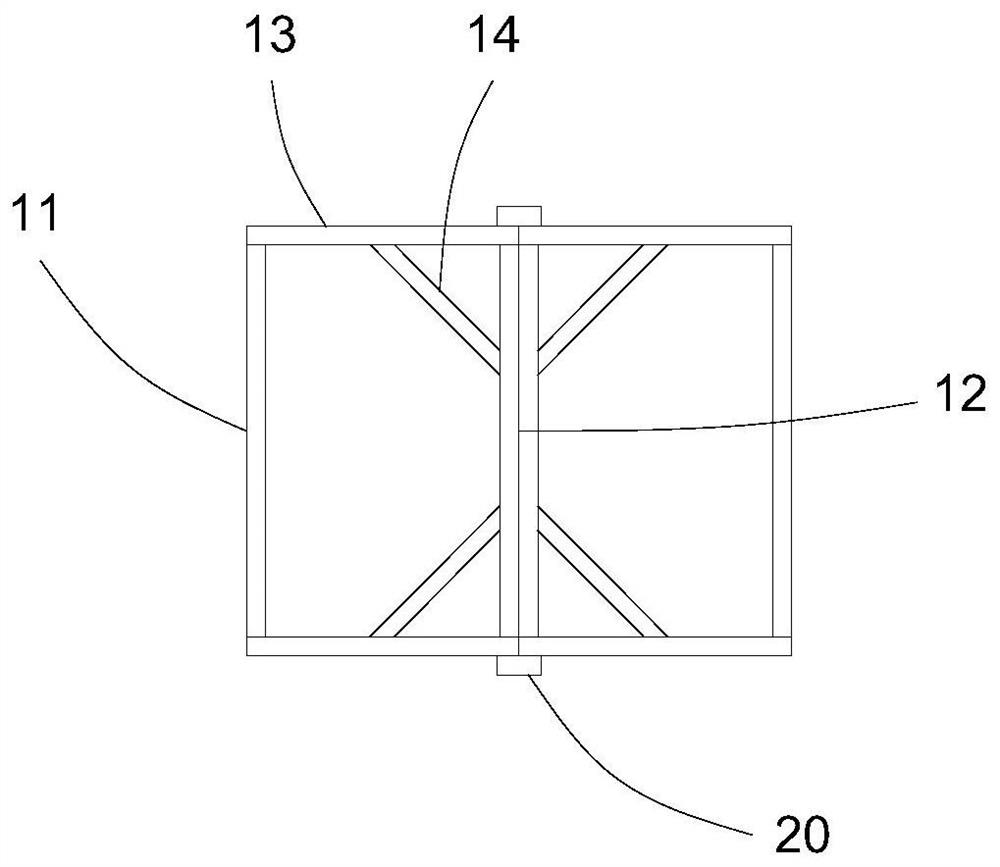

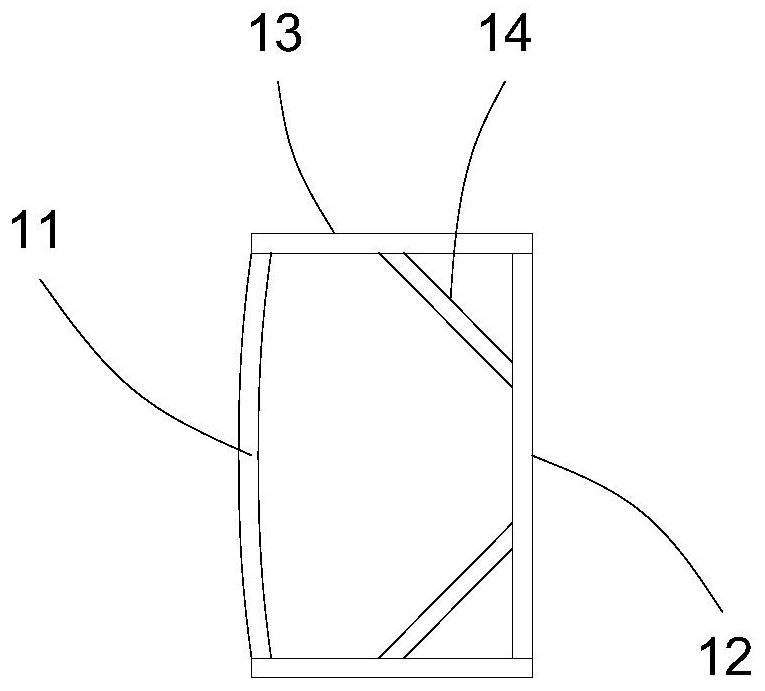

[0025] refer to Figure 1 to Figure 5 .

[0026] The embodiment of the present invention discloses a single-sided assembly method for deformation-resistant steel components, which includes the following steps:

[0027] S1, spare plate, prepare two groups of steel plates, each group of steel plates includes a panel 11, a back plate 12, two side plates 13 and two oblique support plates 14, the shape area of the panel 11 and the back plate 12 is the same, the panels 11, The back plate 12, the side plate 13 and the inclined support plate 14 have the same height, that is, the longitudinal length is equal;

[0028] S2, pre-assembled, pre-assembled two sets of steel plates to obtain two pre-assembled fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com