How to use the on-hook tooling of the piston assembly of the marine low-speed diesel engine

A diesel engine and piston technology is applied in the field of assembly tooling for diesel engine components, which can solve the problems of inconvenient closing and connection, prolonging the installation period of marine low-speed diesel engines, and insecurity, so as to improve assembly efficiency and assembly safety, shorten assembly period, and reduce assembly. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

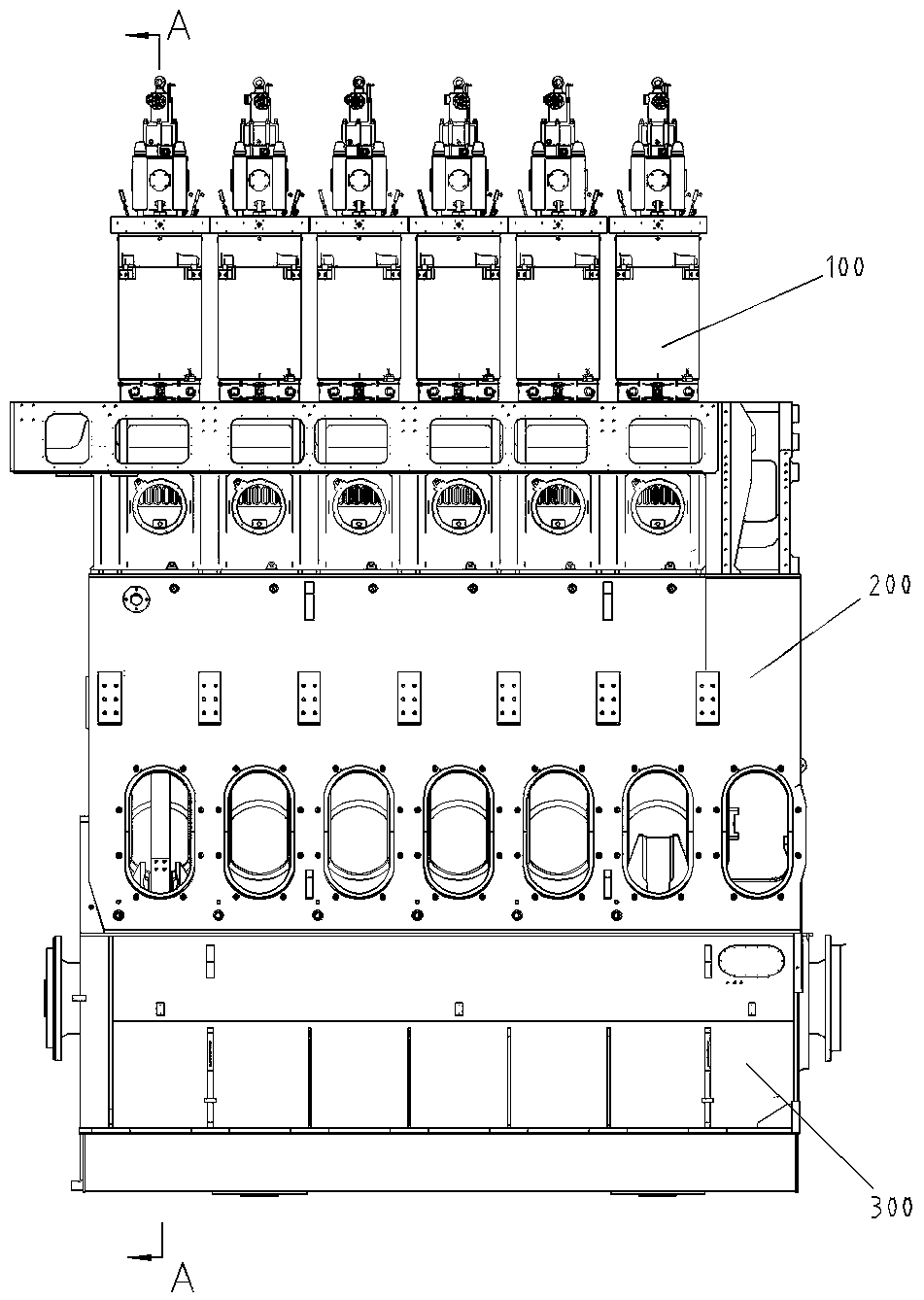

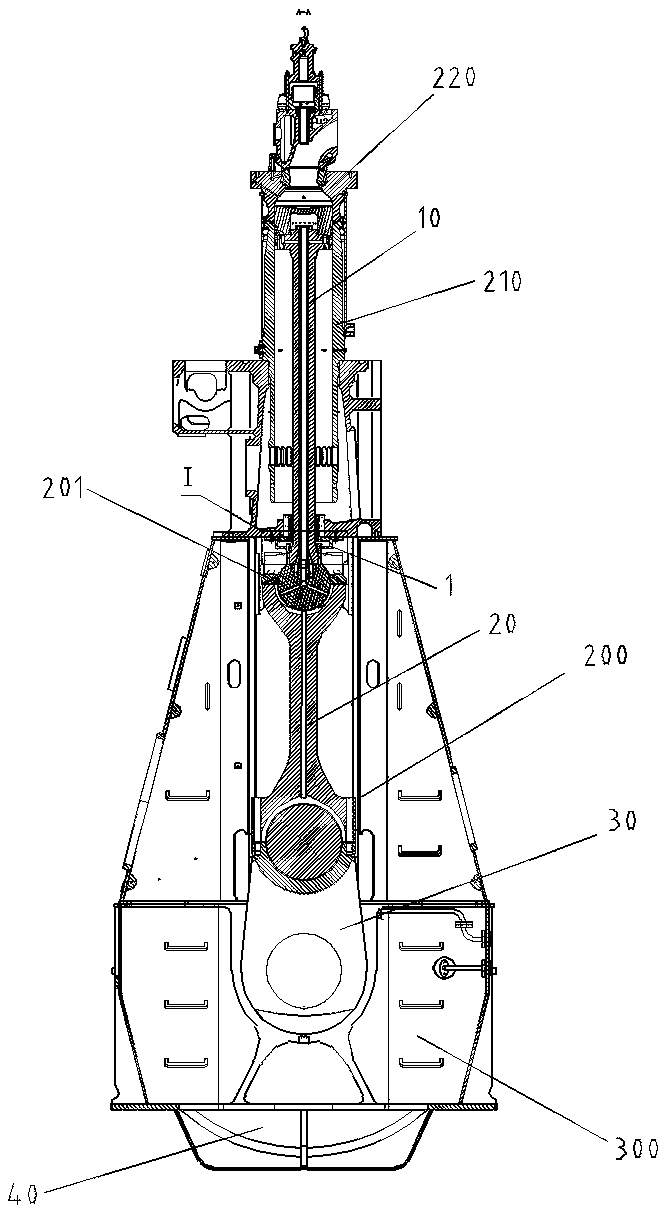

[0028] Below in conjunction with accompanying drawing and the embodiment of MAN B&W 6S40ME-B9.5 type marine low-speed diesel engine, the present invention will be further described.

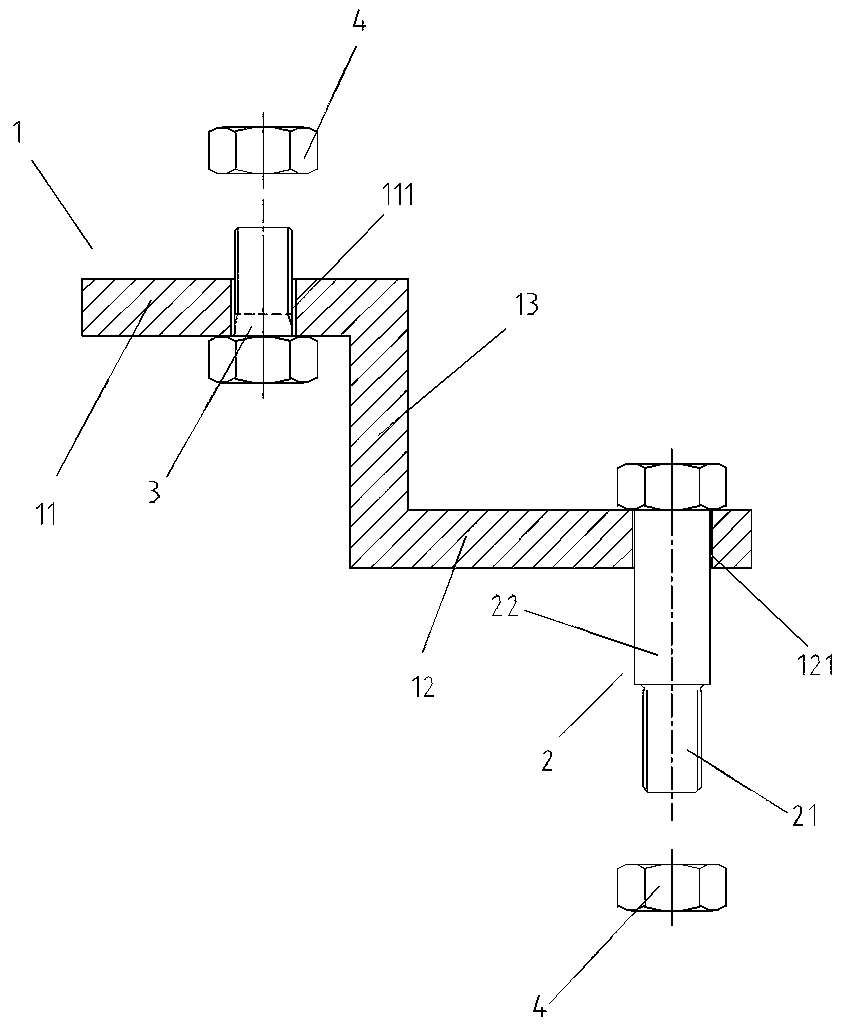

[0029] like image 3 As shown, the device of the present invention includes a bracket 1, a special screw for piston connection 2 and a cylinder block connecting screw 3. The bracket 1 is a welded structural member, which includes an upper horizontal edge 11 and a lower horizontal edge 12 arranged in parallel, and the right end of the upper horizontal edge 11 And lower horizontal edge 12 left ends are welded into Z-shaped by vertical edge 13. An upper connection hole 111 is provided in the middle of the upper horizontal side 11 , and a lower connection hole 121 is provided at the right end of the lower horizontal side 12 . like Figure 4 As shown, when the piston assembly 10 is on-hook, the lower end of the special screw for piston connection 2 passes vertically downward through the lower connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com