Turbine assembling method, turbine assembling auxiliary system, and recording medium

一种涡轮机组、辅助系统的技术,应用在机器/发动机、通用控制系统、控制/调节系统等方向,能够解决降低静止体精度、影响涡轮机的定期检查作业期间、螺栓大等问题,达到缩短组装期间的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach >

[0027] (structure)

[0028] 1. Turbine

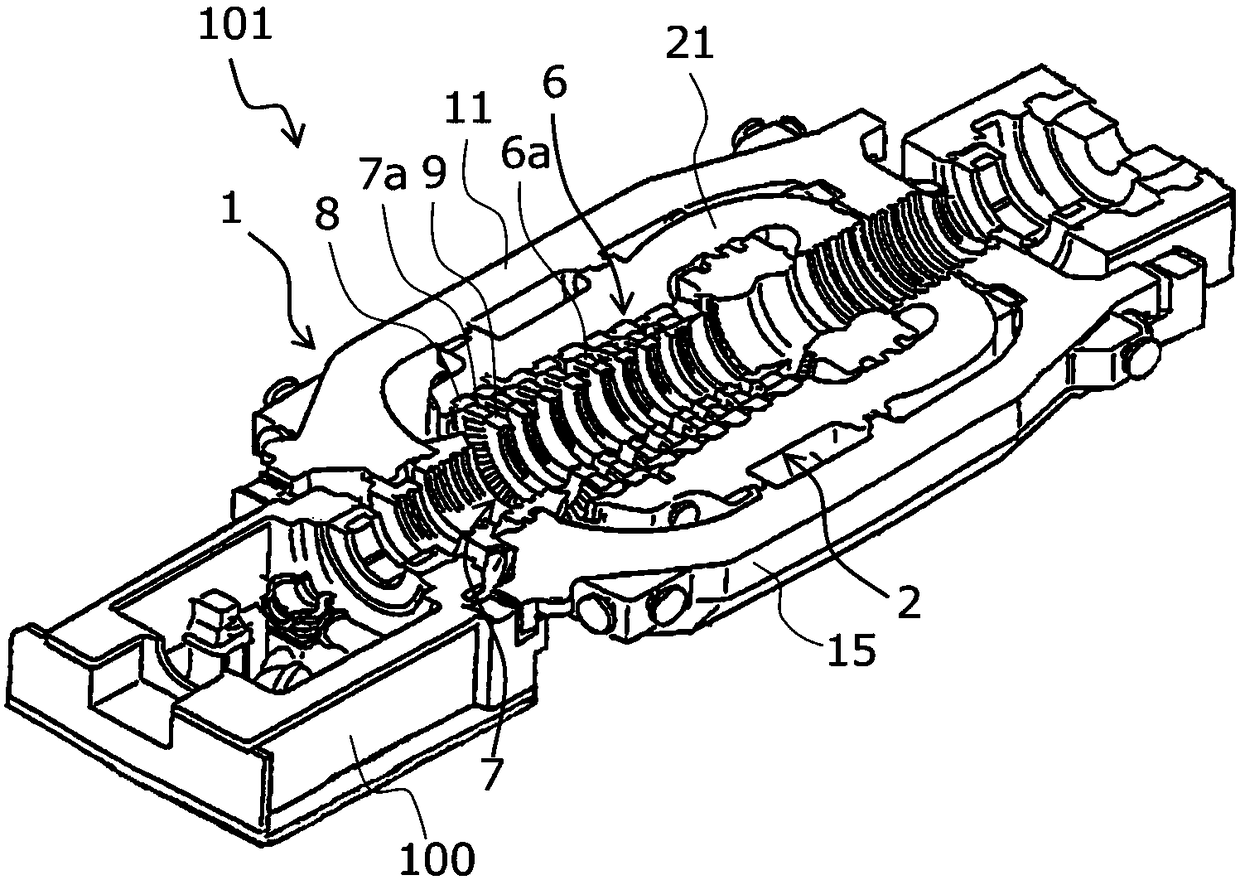

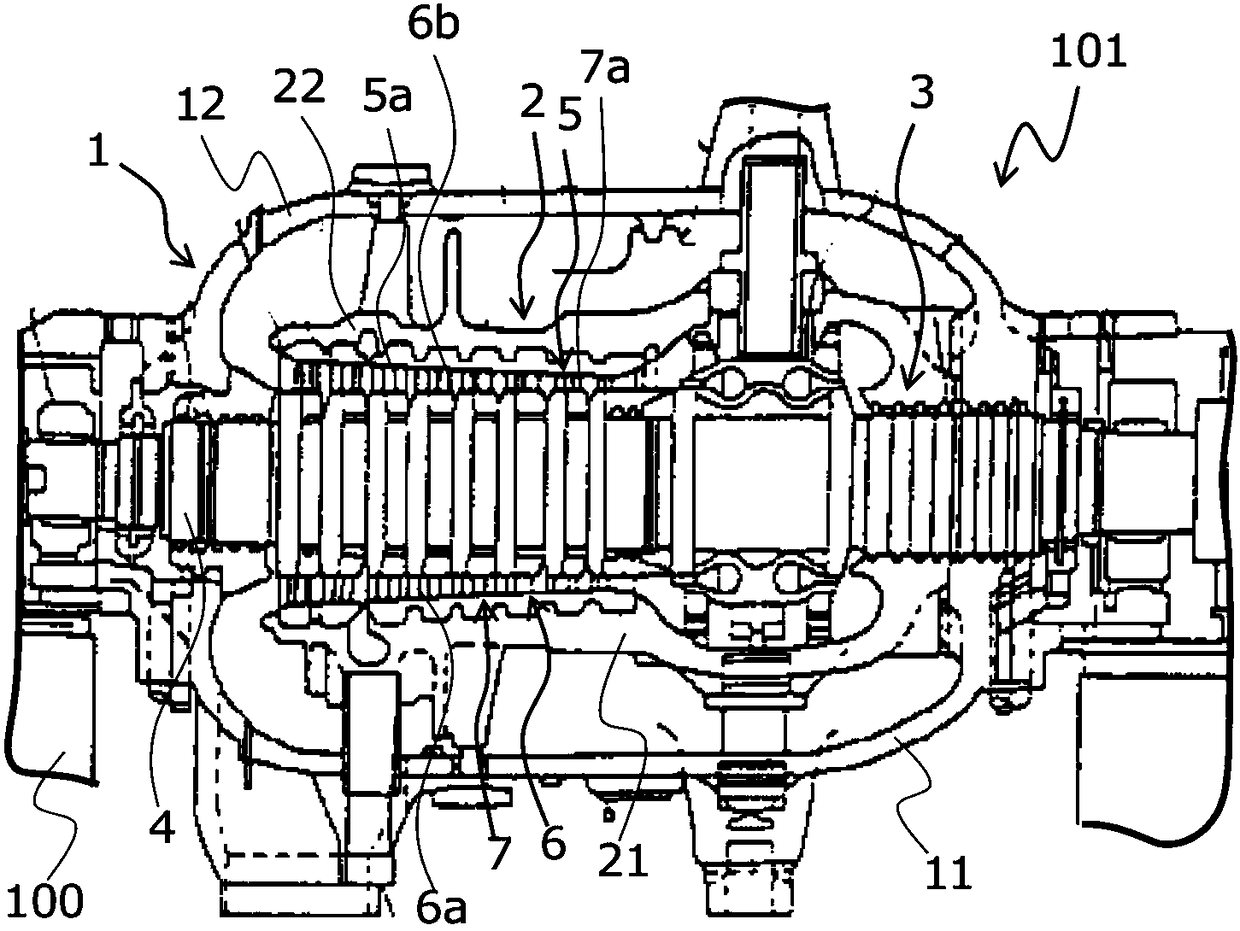

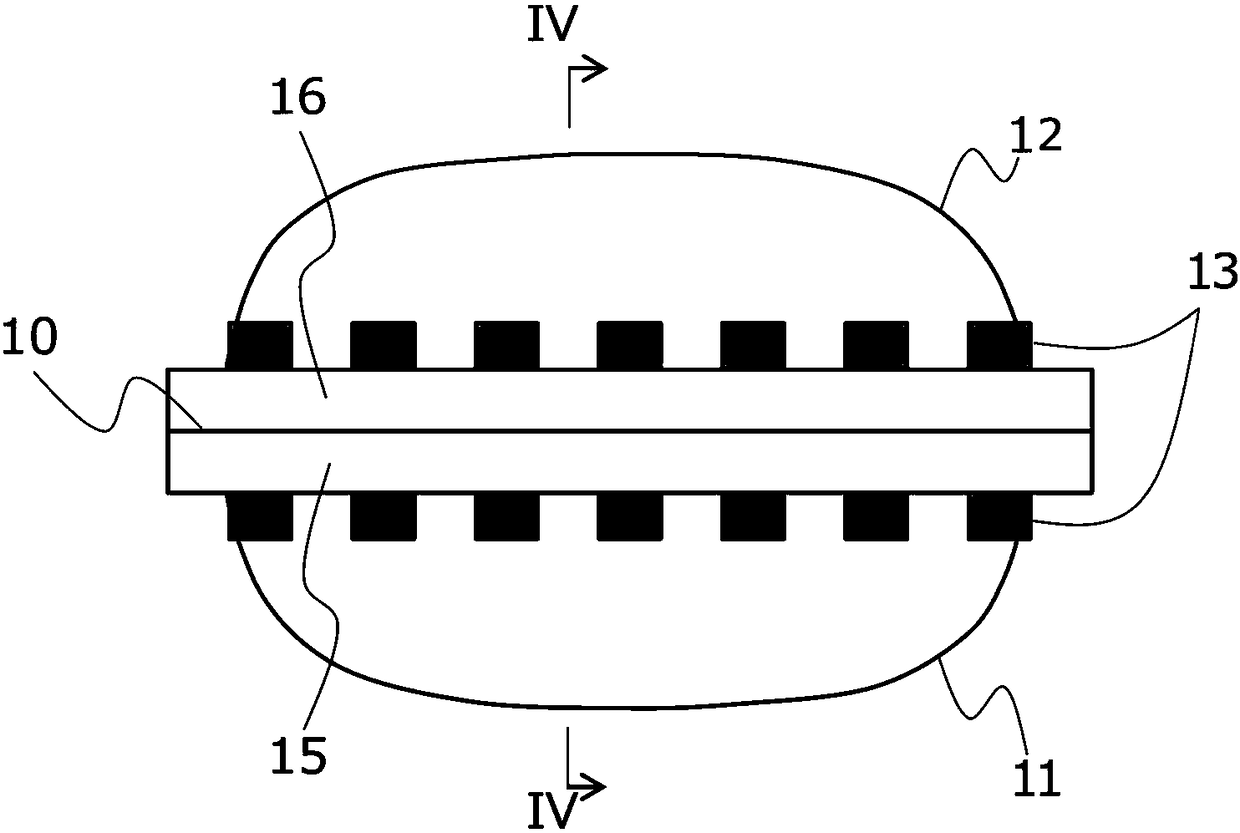

[0029] figure 1 is a perspective view showing the lower half of a steam turbine to which the assembly method according to this embodiment can be applied, figure 2 is a longitudinal sectional view showing a steam turbine to which the assembly method according to this embodiment can be applied, image 3 It is a side view showing the outer chamber of the steam turbine to which the assembly method according to this embodiment can be applied, Figure 4 yes image 3 The arrow profile of the arrow IV-IV line.

[0030] Such as figure 1 , 2 As shown, a steam turbine 101 according to this embodiment includes an outer cabin 1 supported by a frame 100 , an inner cabin 2 housed inside the outer cabin 1 , and a turbine rotor 3 enclosed in the inner cabin 2 . The load of the turbine rotor 3 is supported, for example, by a stand 100 .

[0031] Such as Figure 1~4 As shown, the outer cabin 1 is divided up and down by a horizontal plane (a plan...

no. 2 Embodiment approach >

[0104] Figure 9 It is a flowchart showing the flow of the assembly method according to this embodiment. exist Figure 9 in, right with Figure 6 In the shown flowcharts, the same steps are attached with the same symbols, and explanations thereof are appropriately omitted. Hereinafter, the assembly method according to this embodiment will be described.

[0105] The turbine assembly method according to the present embodiment is different from the turbine assembly method according to the first embodiment in that it further includes step P0. In addition, it is the same as the method of assembling the turbine according to the first embodiment.

[0106] · Step P0

[0107] The measurement data of the shapes of the upper half cabin and the lower half cabin during manufacture are acquired, and the acquired measurement data of the shapes of the upper half cabin and the lower half cabin during manufacture are reflected in the turbine model. Specifically, the flow of obtaining the ...

no. 3 Embodiment approach >

[0113] Figure 10 It is a flowchart showing the flow of the assembly method according to this embodiment. exist Figure 10 in, right with Figure 9 In the shown flowcharts, the same steps are attached with the same symbols, and explanations thereof are appropriately omitted. Hereinafter, the assembly method according to this embodiment will be described.

[0114] This embodiment is suitable for installation of steam turbines at the time of construction of a power plant equipped with steam turbines. Specifically, the assembling method according to the present embodiment differs from the assembling method according to the second embodiment in that step B1a is provided instead of step B1, and step P1a is provided instead of step P1. In addition, it is the same as the assembly method concerning 2nd Embodiment.

[0115] · Step B1a

[0116] The lower half of the outer compartment 11, the lower half of the inner compartment 21 and the bearings are provided. Specifically, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com