Carrier tape coiling device

A technology of winding device and carrier tape, which is applied in the direction of transportation and packaging, thin material handling, and delivery of filamentous materials, etc., can solve the problems of low efficiency, incomplete automation, and high labor intensity of workers, so as to save costs, The effect of reducing the labor intensity of workers and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

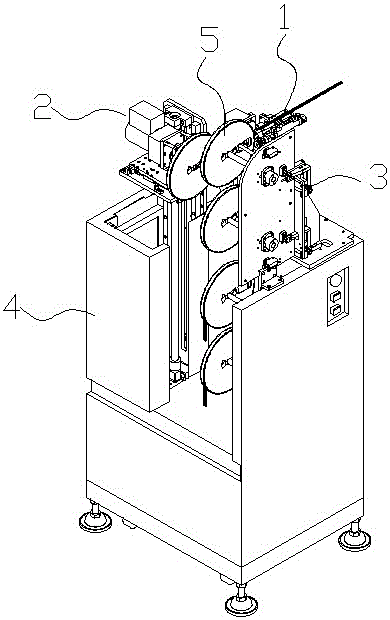

[0033] see Figure 1-Figure 14 , The present invention relates to a carrier tape multi-disc rewinding system, which includes a carrier tape feeding device 1 , a carrier tape rewinding device 2 and a reel storage device 3 . The carrier tape rewinding device 2 is used for rewinding the carrier tape on the carrier tape feeding device 1, and the reel storage device 3 is used for storing the empty reel before rewinding and the full reel after rewinding. The device 1 is used to send the carrier tape head to the empty tray on the carrier tape winding device 2 . The carrier tape winding device 2 and the tray storage device 3 are installed in the same case 4 , and a frame plate 401 arranged longitudinally is arranged in the case 4 .

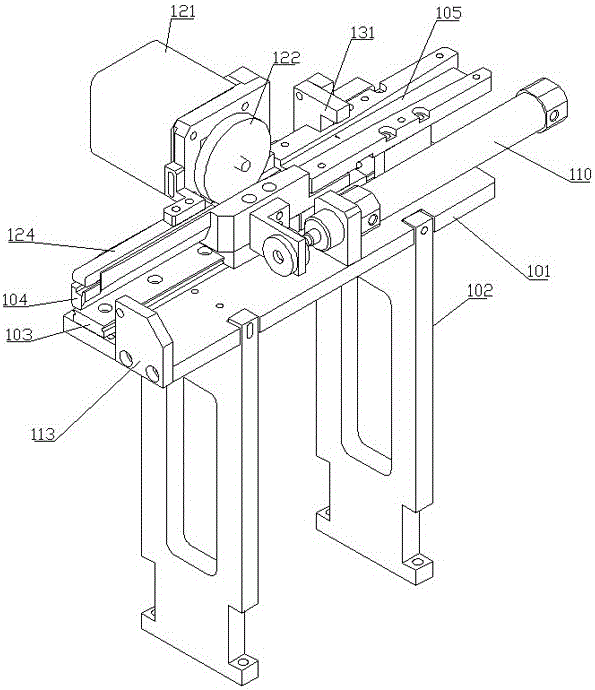

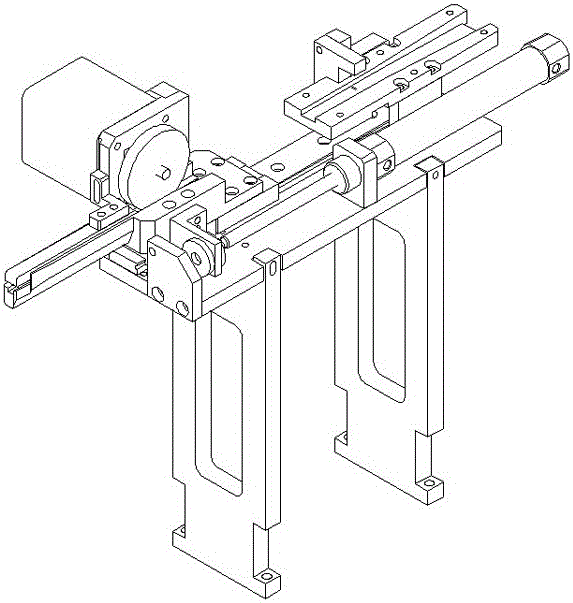

[0034] The carrier tape feeding device 1 includes a track assembly, a feeding assembly and a transmission assembly;

[0035] The track assembly includes a track installation base plate 101, a track installation base plate support foot 102, a moving trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com