Mono-component polyurethane protective film pressure-sensitive adhesive and synthesis process thereof

A synthesis process and pressure-sensitive adhesive technology, applied in polyurea/polyurethane adhesives, polymer adhesive additives, film/sheet adhesives, etc., to achieve good compatibility and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

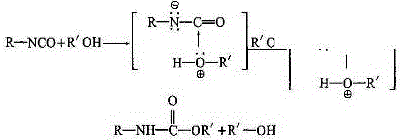

Method used

Image

Examples

Embodiment 1

[0022] A one-component polyurethane protective film pressure-sensitive adhesive in the present invention, said single-component polyurethane protective film pressure-sensitive adhesive is made of the following raw materials in mass fraction:

[0023] Polyether polyol (polyoxyglycerol EP-330N): 56%;

[0024] Catalyst (zinc salt of carboxylate): 0.5%;

[0025] Solvent (butanone): 34%;

[0026] Modified polysiloxane: 0.5%;

[0027] Blocked hexamethylene diisocyanate: 9%.

[0028] The synthesis process of the single-component polyurethane protective film pressure-sensitive adhesive described in the present invention specifically includes the following steps: the weighed polyether polyol, catalyst, solvent, modified polysiloxane, closed polyhexaethylene Methyl diisocyanate was added into the stirring tank according to the above ratio, stirred evenly under normal temperature drying, and sealed and packaged to obtain a pressure-sensitive adhesive. When using, the pressure-sensitiv...

Embodiment 2

[0030] A one-component polyurethane protective film pressure-sensitive adhesive in the present invention, said single-component polyurethane protective film pressure-sensitive adhesive is made of the following raw materials in mass fraction:

[0031] Polyester polyol (polypropylene adipate): 60%;

[0032] Catalyst (zinc salt of carboxylate): 0.5%;

[0033] Solvent (butanone): 27%;

[0034] Modified polysiloxane: 0.5%;

[0035] Blocked hexamethylene diisocyanate: 12%.

[0036] The synthesis process of the single-component polyurethane protective film pressure-sensitive adhesive described in the present invention specifically includes the following steps: the weighed polyether polyol, catalyst, solvent, modified polysiloxane, closed polyhexaethylene Methyl diisocyanate was added into the stirring tank according to the above ratio, stirred evenly under normal temperature drying, and sealed and packaged to obtain a pressure-sensitive adhesive. When using, the pressure-sensitive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com