Construction method and application of recombinant mold capable of increasing yield of citric acid

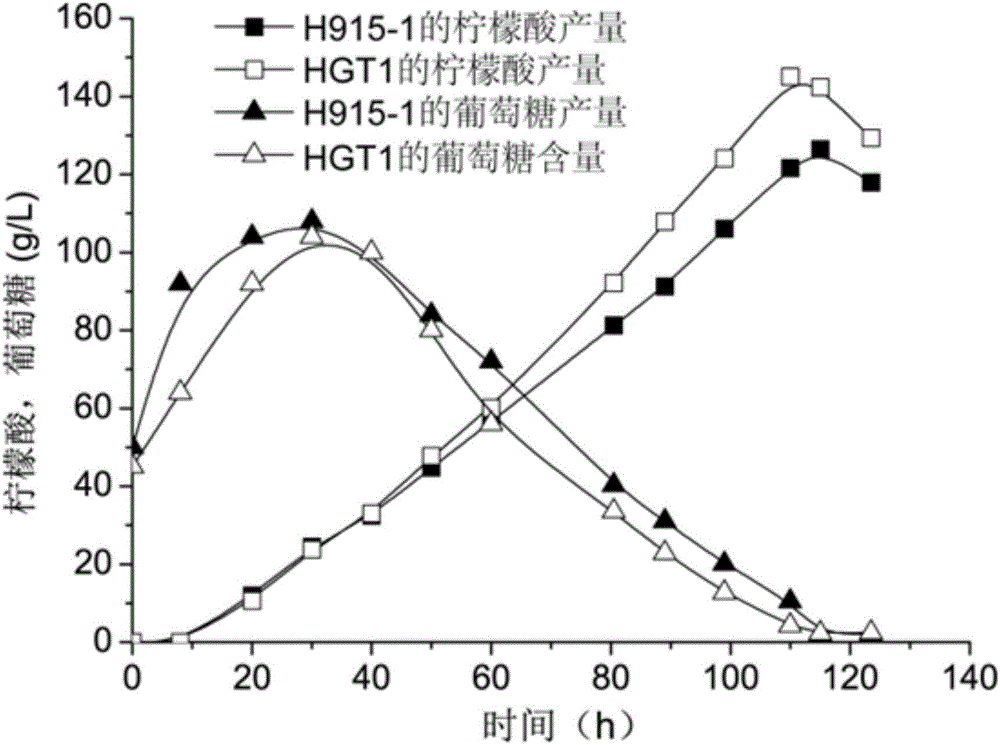

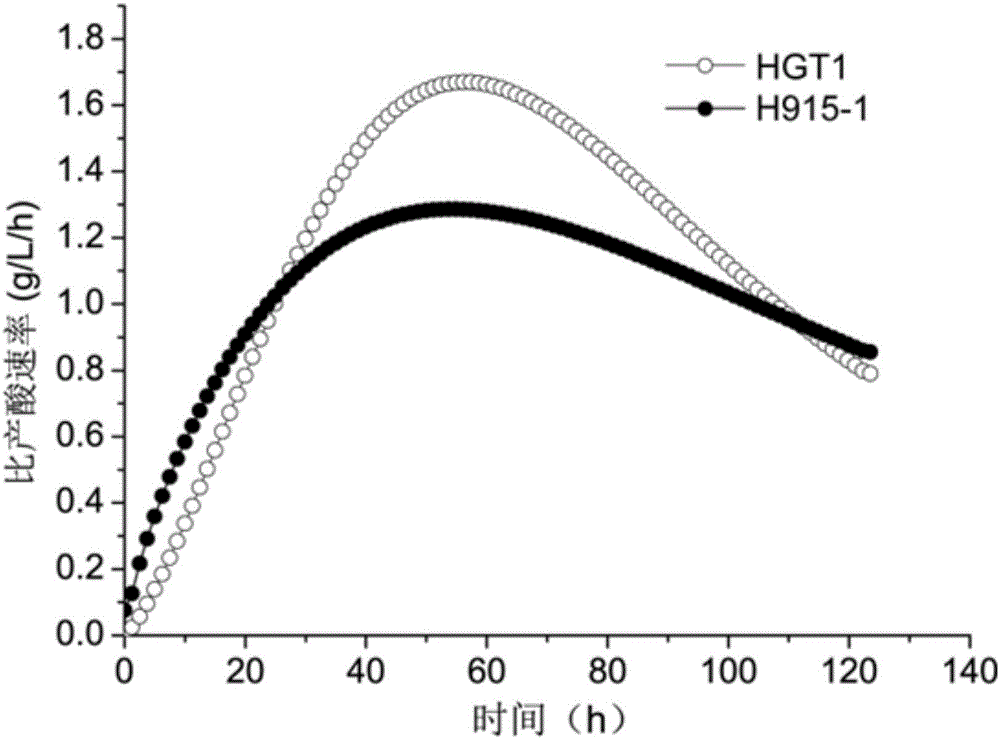

A technology for increasing production and constructing methods, which is applied in the field of bioengineering to achieve the effects of increasing production, shortening fermentation cycle, and increasing citric acid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1 Extraction of Aspergillus niger RNA

[0044] Inoculate Aspergillus niger spores into citric acid fermentation medium, culture at 250r / min at 35°C for 48 hours, collect the balls with mirocloth filter cloth, wash them with sterile ultrapure water for 3 times, drain the water and quickly place them in liquid nitrogen freezing. The tissue was thoroughly ground by grinding with liquid nitrogen, and the total RNA of Aspergillus niger was extracted using the QIAGEN RNeasy Plant Mini Kit kit. The RNA was reverse-transcribed into cDNA with TAKARA PrimeScript RT reagent Kit with gDNA Eraser.

Embodiment 2

[0045] Example 2 Extraction of Aspergillus niger Genomic DNA

[0046] Aspergillus niger spores were inoculated into ME liquid medium (3% malt extract, 0.5% tryptone), cultured at 250r / min at 35°C for 48h, the balls were collected with a mirocloth filter cloth, and washed with sterile ultrapure water for 3 After drying, the water was quickly frozen in liquid nitrogen. The tissue was thoroughly ground by grinding with liquid nitrogen, and the genome of filamentous fungi was extracted using DNeasy Plant MiniKit from QIAGEN.

Embodiment 3

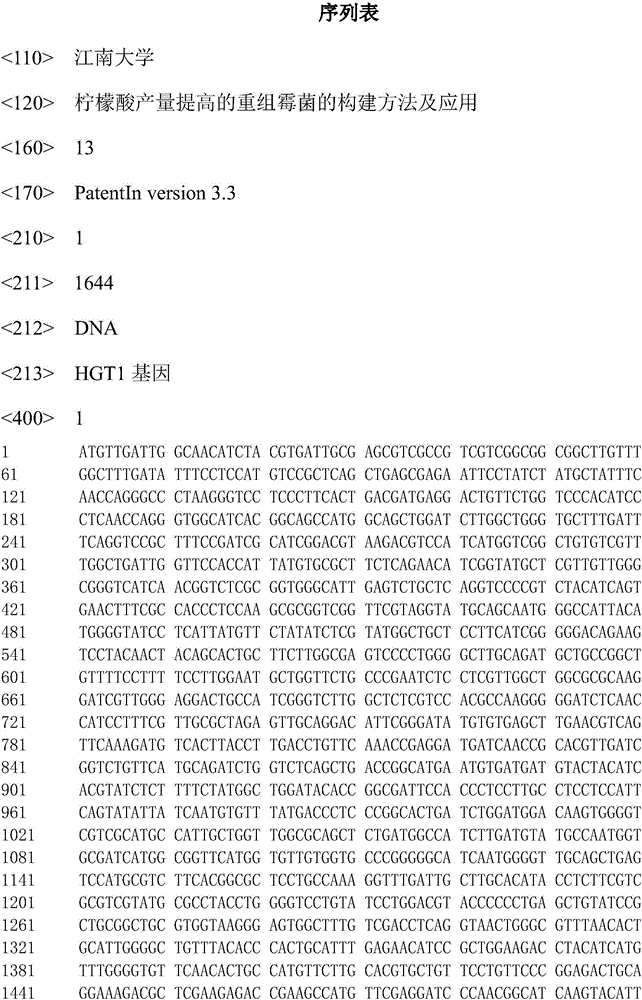

[0047] Example 3 Construction of HGT1 protein expression cassette and hygromycin resistance expression cassette

[0048] Use primers trp-F (sequence shown in SEQ ID NO.6) and trp-R (sequence shown in SEQ ID NO.7) to amplify the trp terminator with pAN7-1 as a template, and the upstream and downstream sequences contain Pst I and The Hin dIII digestion site was connected to pMD19 for sequencing, and then digested with these two restriction endonucleases, and the sequence was connected to the same digested pUC19 to obtain pUC19-trp.

[0049]Use primers Pgpd-F (sequence shown in SEQ ID NO.8) and Pgpd-R (sequence shown in SEQ ID NO.9) to amplify the PgpdA promoter from pAN7-1, and the sequence contains Eco RI and Kpn I at both ends Restriction site, after digestion, the sequence was connected to pUC19-trp that was also digested to obtain pUC-PgpdA-trp.

[0050] Utilize primer HGT1-F (sequence as shown in SEQ ID NO.10) and HGT1-R (sequence as shown in SEQ ID NO.11) to amplify HGT1 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap