Fixing device and method of steel billet in stuffy slag pit

A fixing device and fixing method technology, applied in the direction of recycling technology, etc., can solve the problems of affecting the service life of the slag pit, high cost, affecting the progress of the project, etc., achieving good practicability and economic benefits, reducing complexity, and saving production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

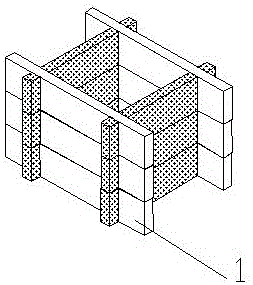

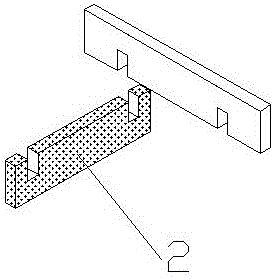

[0030] Embodiment 1: as image 3 As shown, two slots 3 are arranged on the billet unit 2, and the two slots are arranged on the same surface, which can facilitate plugging. Such as Figure 4 As shown, the steel billet fixing unit 1 is formed by inserting a single billet A21 and a single billet B22.

Embodiment 2

[0031] Embodiment 2: as Figure 5 As shown, two slots 3 are provided on the steel billet unit C23, and the slots 3 are respectively provided on the upper surface and the lower surface, which can ensure the tight connection between the steel billet units 2. It is connected as Figure 6 shown.

Embodiment 3

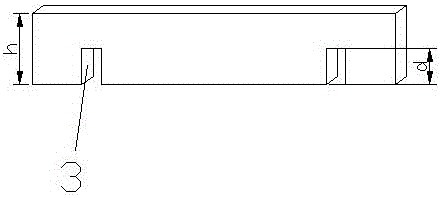

[0032] Embodiment 3: On the basis of Embodiments 1 and 2, the ratio of the groove depth d of the slot 3 to the height h of the single billet 2 is 1:2, which can ensure the upper surface of the single billet 2 that cooperates with each other and the lower surface can be on the same plane respectively, so as to prevent the steel billet fixing unit 1 from swaying and causing safety accidents due to scattered support points during use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com