A kind of cold-rolled steel plate with a yield strength of 500mpa and its preparation method

A technology of yield strength and cold-rolled steel plate, which is applied in the field of cold-rolled steel plate with yield strength of 500MPa and its preparation, can solve the problems of increased movable dislocation density, difficulty in obtaining high yield ratio, and influence on precipitation strengthening effect, etc., to achieve reduction Difficult to control, low cost, guaranteed effect of precipitation strengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

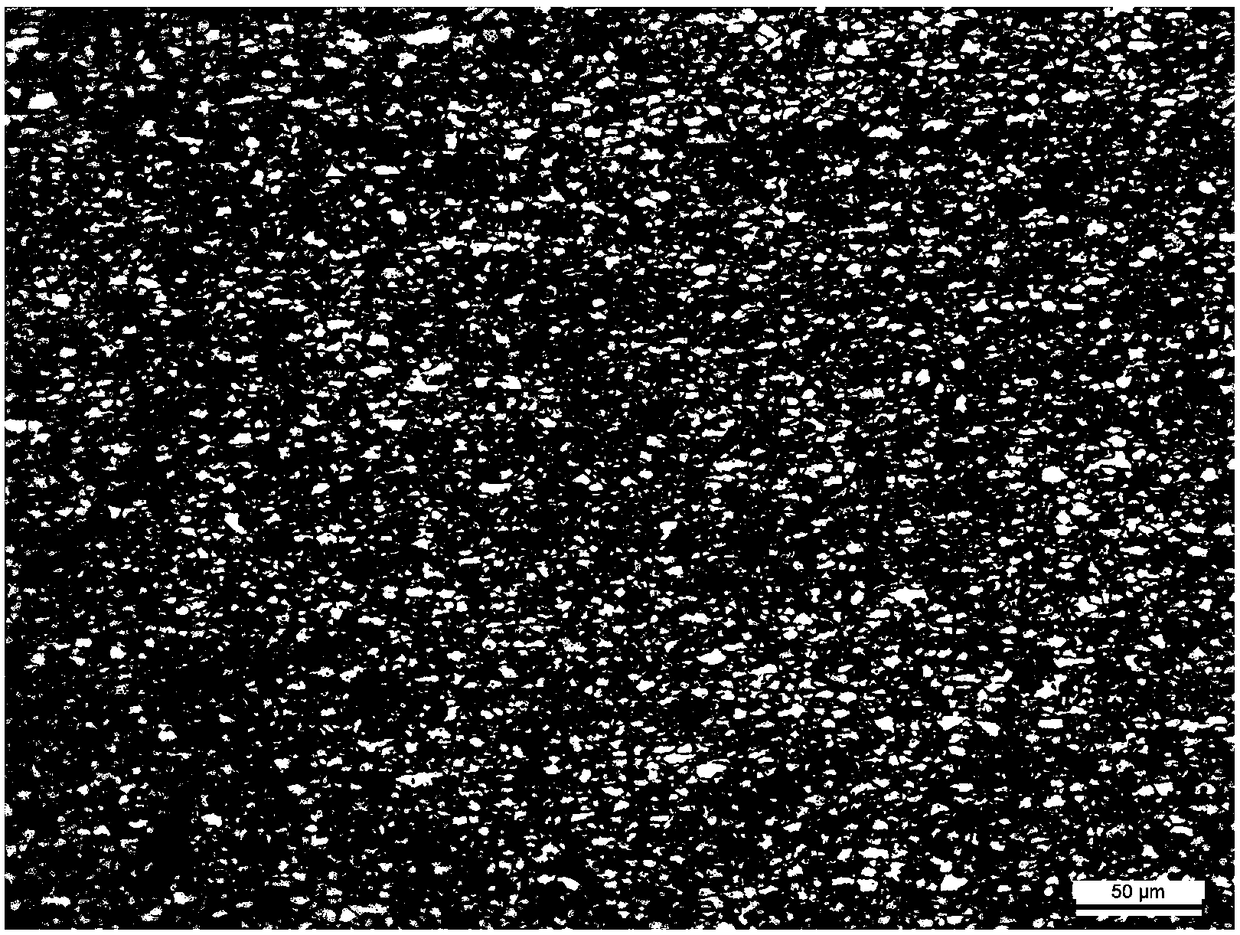

Image

Examples

Embodiment 1

[0052] A cold-rolled steel plate with a yield strength of 500MPa, the composition and mass percentage are: C: 0.07%, Si: 0.03%, Mn: 0.9%, Nb: 0.02%, Ti: 0.04%, and the rest is Fe and unavoidable impurities element; its thickness is 1.5mm.

[0053] The preparation method of above-mentioned yield strength 500MPa grade cold-rolled steel plate, comprises the steps:

[0054] Step 1, smelting and forging:

[0055] According to the chemical composition of the 500MPa yield strength cold-rolled steel plate, the raw materials are selected and mixed, and then smelted into ingots; among them, the yield strength 500MPa grade cold-rolled steel plate has the composition and mass percentage of C: 0.07%, Si: 0.03%, Mn : 0.9%, Nb: 0.02%, Ti: 0.04%, the rest is Fe and unavoidable impurity elements; the ingot is forged into a 40mm thick slab;

[0056] Step 2, hot rolling:

[0057] (1) Heat the forged slab at 1240°C for 2.5 hours;

[0058] (2) Hot-rolling the slab after heat preservation, the ...

Embodiment 2

[0073] A cold-rolled steel plate with a yield strength of 500MPa, the composition and mass percentage are: C: 0.06%, Si: 0.1%, Mn: 0.95%, Nb: 0.03%, Ti: 0.03%, and the rest is Fe and unavoidable impurities element; its thickness is 1.2 mm.

[0074] The preparation method of above-mentioned yield strength 500MPa grade cold-rolled steel plate, comprises the steps:

[0075] Step 1, smelting and forging:

[0076] According to the chemical composition of the 500MPa yield strength cold-rolled steel plate, the raw materials are selected and blended, and then melted into ingots; among them, the yield strength 500MPa grade cold-rolled steel plate, the composition and its mass percentage are: C: 0.06%, Si: 0.1%, Mn: 0.95%, Nb: 0.03%, Ti: 0.03%, the rest is Fe and unavoidable impurity elements; the ingot is forged into a 50mm thick slab;

[0077] Step 2, hot rolling:

[0078] (1) Heat the forged slab at 1250°C for 3 hours;

[0079] (2) Hot-rolling the slab after heat preservation, th...

Embodiment 3

[0094] A cold-rolled steel plate with a yield strength of 500MPa, the composition and mass percentage are: C: 0.09%, Si: 0.03%, Mn: 0.8%, Nb: 0.04%, Ti: 0.02%, and the rest is Fe and unavoidable impurities element; its thickness is 0.5 mm.

[0095] The preparation method of above-mentioned yield strength 500MPa grade cold-rolled steel plate, comprises the steps:

[0096] Step 1, smelting and forging:

[0097] According to the chemical composition of the 500MPa yield strength cold-rolled steel plate, the raw materials are selected and mixed, and then melted into ingots; among them, the yield strength 500MPa grade cold-rolled steel plate, the composition and its mass percentage are: C: 0.09%, Si: 0.03% , Mn: 0.8%, Nb: 0.04%, Ti: 0.02%, the rest is Fe and unavoidable impurity elements; the ingot is forged into a 35mm thick slab;

[0098] Step 2, hot rolling:

[0099] (1) Insulate the forged slab at 1200°C for 3 hours;

[0100] (2) Hot-rolling the slab after heat preservation,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com