Detachable cotton catching beater

A cotton grabbing and detachable technology, which is applied in the field of detachable cotton grabbing and beaters, can solve the problems of difficult installation, increased production cost, difficult maintenance, etc., and achieves convenient maintenance and cleaning, convenient installation and disassembly, and low failure rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

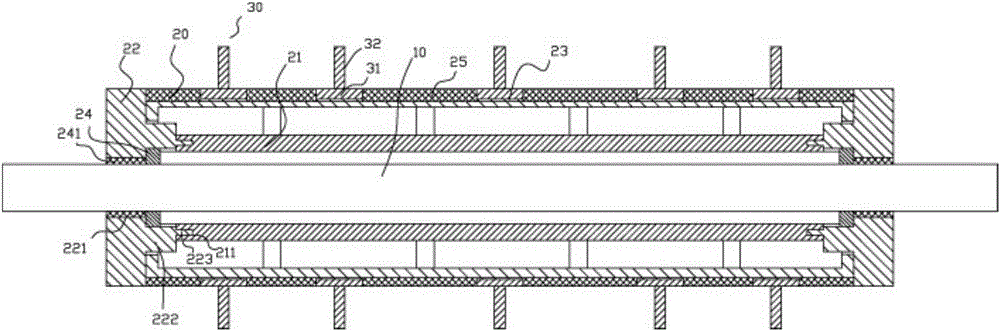

[0019] Example: see figure 1 As shown, a detachable cotton picker includes a mandrel 10, a cylindrical frame body 20 and a plurality of blades 30, the mandrel 10 is inserted in the cylindrical frame body 20, and the inside of the cylindrical frame body 20 There is an intermediate shaft sleeve 21, and the mandrel 10 is inserted into the intermediate shaft sleeve 21. The middle part of the mandrel 10 is a spline shaft part, and the spline protrusion of the spline shaft part is inserted on the inner side wall of the intermediate shaft sleeve 21. In the spline groove, two end caps 22 are located on both sides of the cylindrical frame body 20, and the two end caps 22 are fixedly connected to the two end faces of the cylindrical frame body 20 by bolts, and the two ends of the mandrel 10 protrude from the corresponding The middle part of the end cover 22 has a through hole 221;

[0020] There are a plurality of spline connection protrusions 23 on the outer wall of the cylindrical fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com