Simple installation type bale plucking beater

The utility model relates to a cotton gripper and a simple technology, which is applied in the field of simple installation type cotton gripper and can solve the problems of installation difficulty, increase production cost, affect production efficiency, etc., and achieve the effects of convenient maintenance and cleaning, convenient installation and disassembly, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

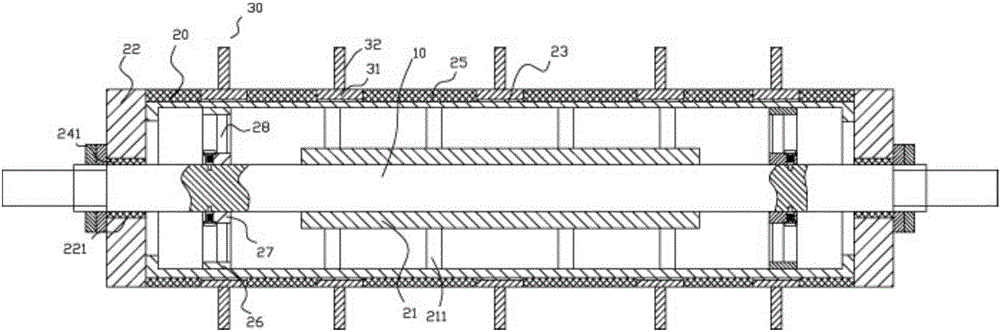

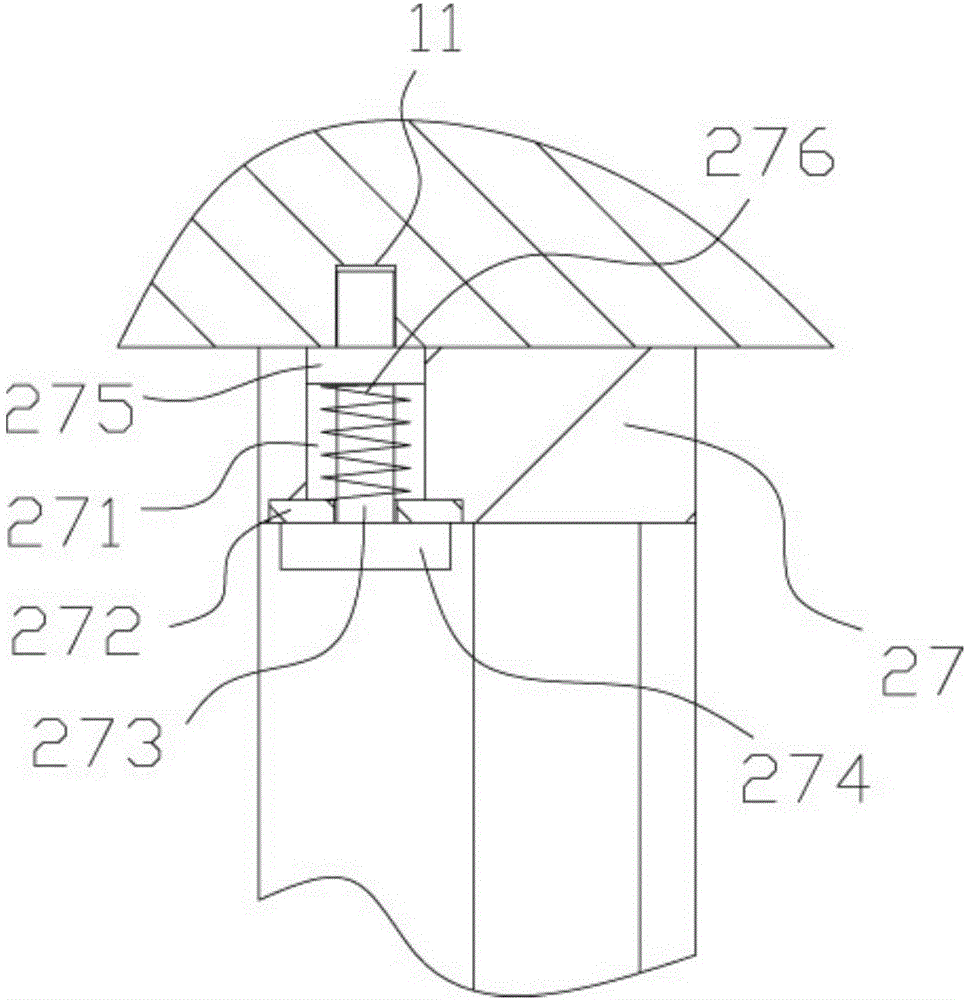

[0020] Example: see Figure 1 to Figure 2 As shown, a simple and easy-to-install cotton picker includes a mandrel 10, a cylindrical frame body 20 and a plurality of blades 30, the mandrel 10 is inserted in the cylindrical frame body 20, and the inside of the cylindrical frame body 20 There is an intermediate shaft sleeve 21, the mandrel 10 is inserted into the intermediate shaft sleeve 21, a plurality of support rods 211 are fixed on the outer wall of the intermediate shaft sleeve 21, and the other ends of the support rods 211 are fixed on the inner side wall of the cylindrical frame body 20 Above, two end caps 22 are located on both sides of the cylindrical frame body 20, and the two end caps 22 are fixedly connected to the two end faces of the cylindrical frame body 20 by bolts, and the two ends of the mandrel 10 protrude from the corresponding end caps. 22 has a through hole 221 in the middle;

[0021] Annular rings 26 are fixed on the inner walls of both ends of the cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com