Sleeper structure and construction method for bonding old and new concrete on ballastless track

A new and old concrete, ballastless track technology, applied in the track, track laying, track maintenance, etc., can solve the problems of increased concrete shrinkage, impact on mechanical performance and durability, increase in cracks between ballast bed and concrete, and achieve simple structure, Significant economic benefits, increase the bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention relates to a sleeper structure and a construction method for bonding new and old concrete of ballastless track, and the structure of the sleeper for bonding new and old concrete of ballastless track is as follows:

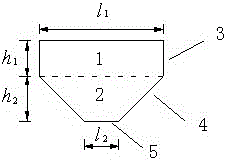

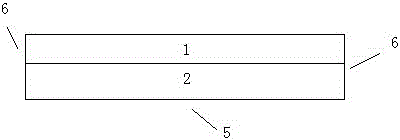

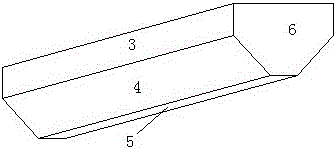

[0017] (1) The sleeper used for ballastless track crack control can be divided into upper and lower parts on the cross section, such as figure 1 As shown, the upper part 1 is a rectangle, and the length of the rectangle is l 1 , the height is h 1 ; That is, the sleeper side 3 of this part does not slope, but adopts a vertical side. The lower part 2 is an isosceles trapezoid with the upper side longer and the lower side shorter, that is, the lower part of the sleeper adopts the form 4 of inward slope, and the slope adopts 1:1. The length of the upper side of the isosceles trapezoid is l 1 , the length of the lower side is l 2 .

[0018] (2) The transverse length of the bottom surface 5 of the sleeper l 2 Controlled at 8~10cm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com