Later-period sub-dam stacking and dam face drainage ditch arrangement mode for tailing pond

A technology for drainage ditches and tailings ponds, applied to water supply devices, drainage structures, fillings, etc., can solve problems such as flushing, dam surface ditch, and impact on dam safety, so as to achieve simple implementation process and protect dam safety , the effect of smooth drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

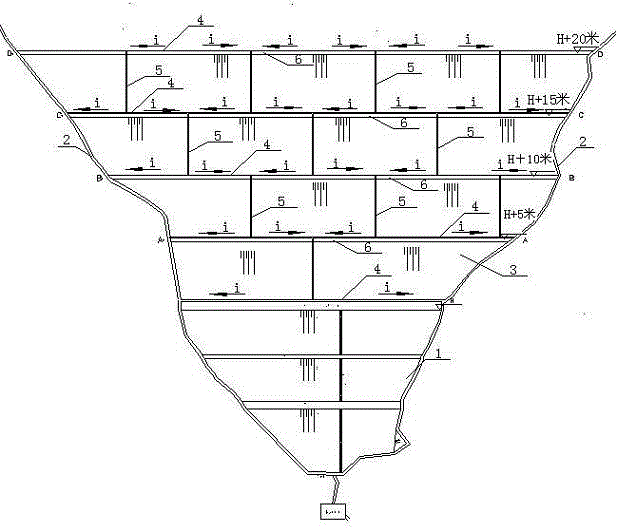

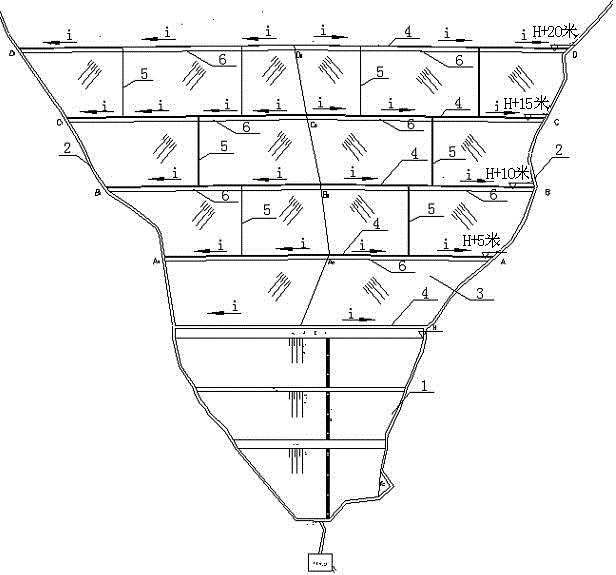

[0014] Such as figure 2 Shown: a method of sub-dam stacking and drainage ditches on the dam surface in the later stage of the tailings pond, which is characterized in that: the tailings pond is used for upstream tailings damming method. The slope of the sub-dam 3 is controlled according to the design slope requirements, while the slope is towards the axis of the initial dam body 1, and at the same time, it is also sloped from the central axis of the accumulation sub-dam to the abutments on both sides. To form two slopes, from the central axis A of the accumulation sub-dam 0 -B 0 -C 0 -D 0 Set slopes to the abutment drainage ditch 2 on both sides and the horseway 6 of the lower sub-dam respectively, and the central axis A 0 -B 0 -C 0 -D 0 The total slope of the dam reaches 4%-9% of the slope requirement of the designed dam surface, and the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com