Electric inflatable concrete formwork sealing device

A concrete formwork, inflatable technology, applied in the connection of formwork/formwork/work frame, the preparation of building components on site, construction, etc., can solve the loss of human life and property, short vibration time, and root formwork sealing It can avoid catastrophic consequences, prevent common root rot, and achieve good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

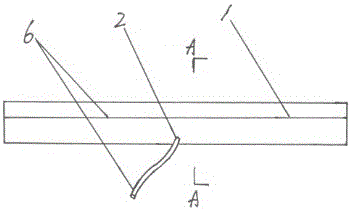

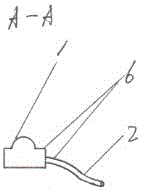

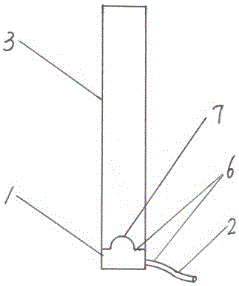

[0011] The invention is attached figure 1 , 2 , 3, and 4, the concrete form sealing structure 6 includes an air bag 1, an air pipe 2, and one end of the air pipe 2 is bonded to the air bag 1; the air bag 1 is a flexible strip, and the top of its section is a semicircular arc The shape and the lower part are rectangular, and the air delivery pipe 2 is a flexible circular strip, one end of which is bonded and communicated with the air bag 1, and the other end is used for inflation.

[0012] The use method and sealing principle of the present invention: the concrete formwork sealing device 6 is designed for the sealing of the wooden formwork 3. First, a section of the formwork sealing device 6 equal to the length of the wooden formwork 3 is intercepted, and the intercepted port is bonded and sealed, and then the wooden formwork is sealed. Formwork 3 ends have semicircle-arc groove 7, and then the semicircle-arc part of this concrete form sealing device 6 is glued in the semicirc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com