Solid-liquid separation device under pressure-holding condition of drilling construction mud in pressurized water formation

A construction mud and solid-liquid separation technology, applied in earthwork drilling, wellbore/well components, flushing wellbore, etc., can solve problems such as unstable mud pressure, difficulty in forming mud and formation water and soil pressure balance, sand gushing, etc. To achieve the effect of ensuring normal advancement, reducing soil erosion, and avoiding disturbance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

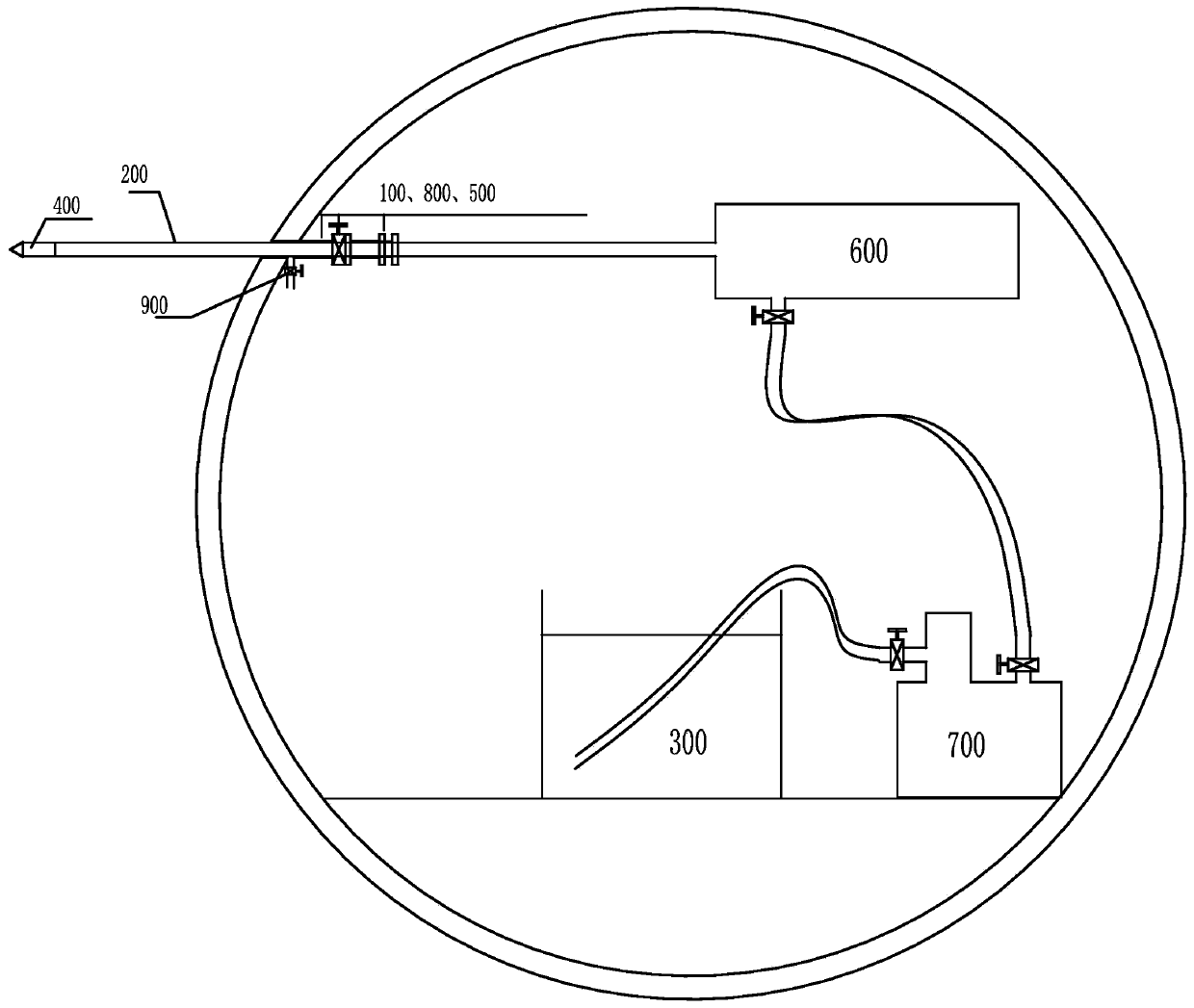

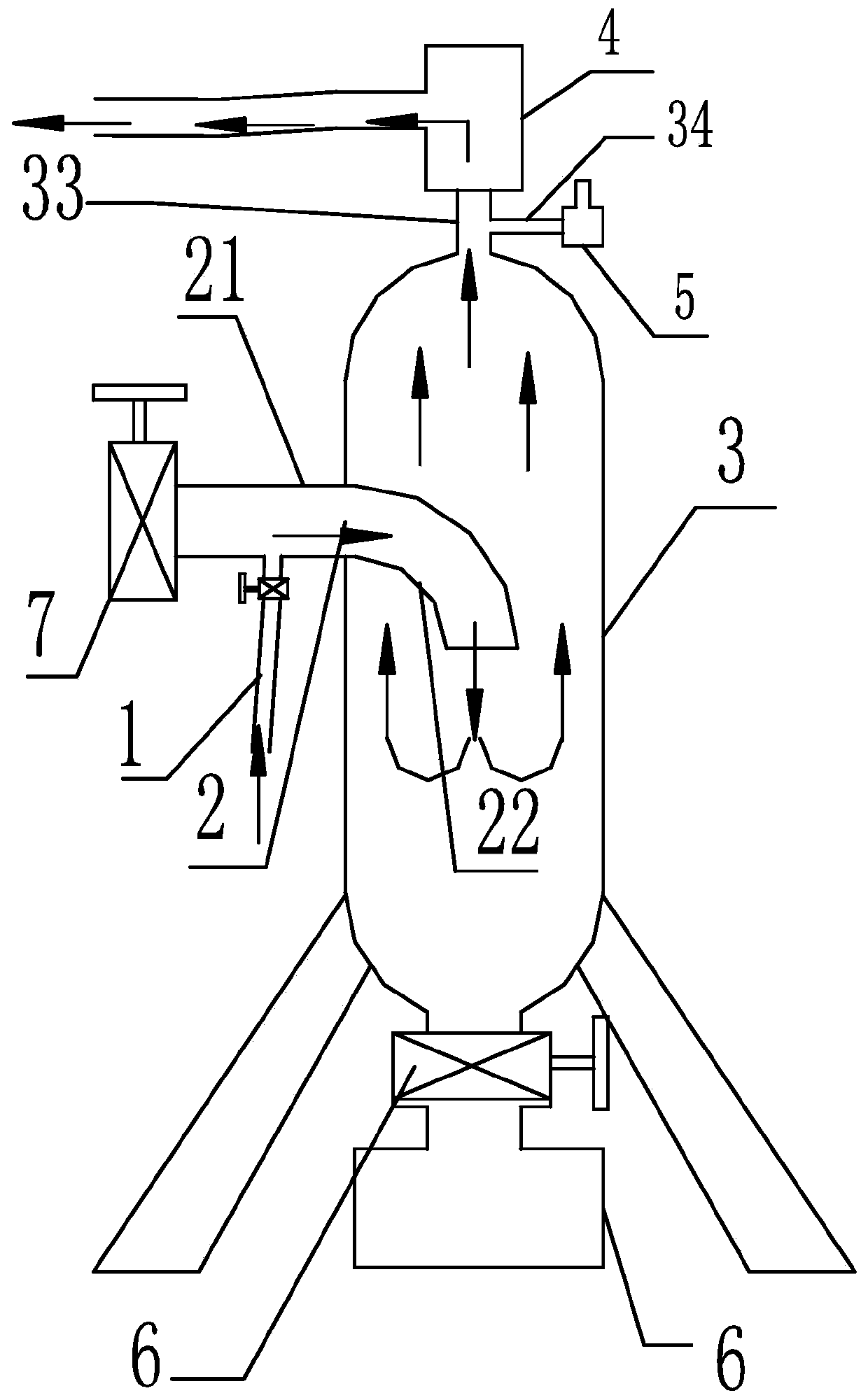

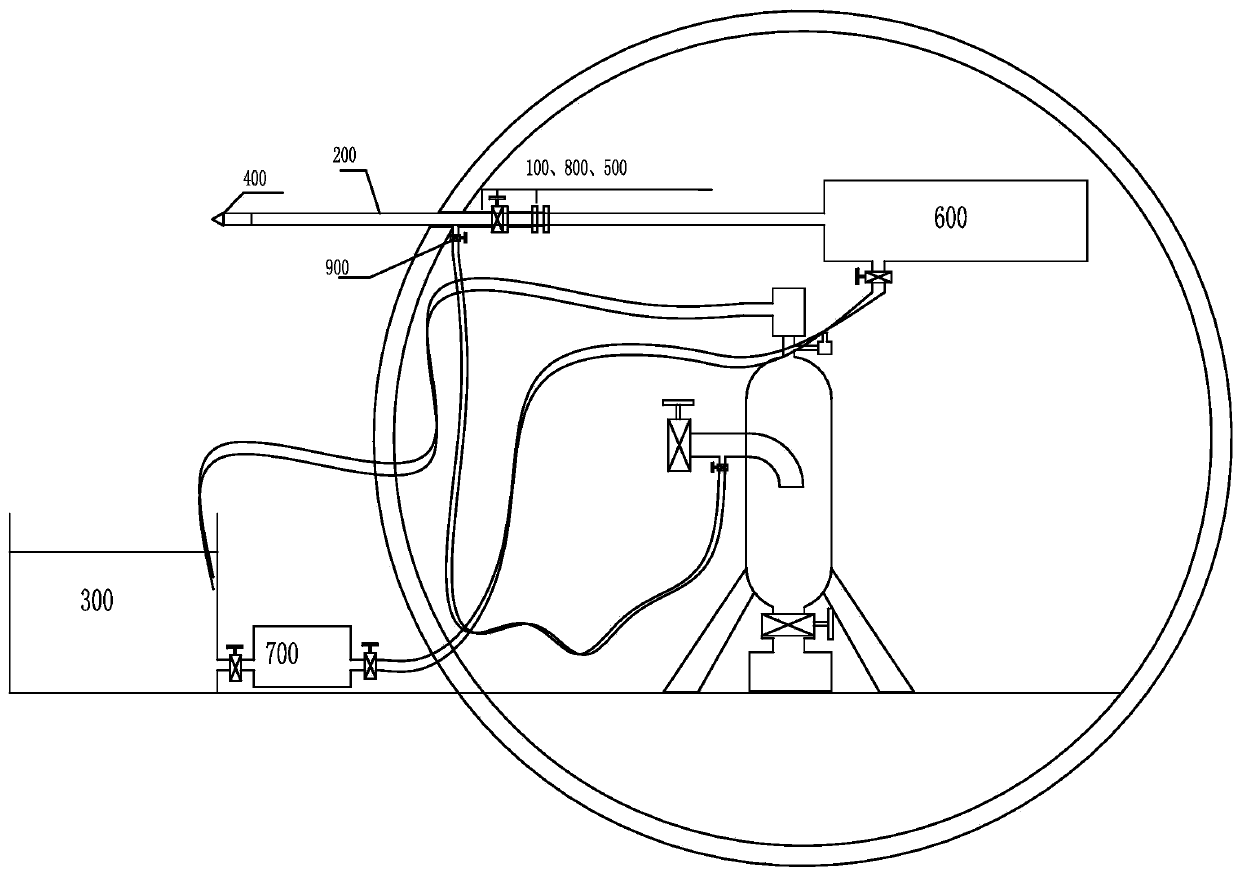

[0028] In order to clearly illustrate the solutions in the present invention, preferred embodiments are given below and detailed descriptions are given in conjunction with the accompanying drawings.

[0029] Such as figure 2 As shown, the solid-liquid separation device in this embodiment includes a first pipeline 1, a second pipeline 2, a slurry tank 3 and an adjustable automatic pressure relief valve 4 under the pressure-holding condition of the drilling construction mud in the pressurized water formation; The inlet of the pipeline 1 is connected with the orifice pipe 100, the outlet of the first pipeline 1 is connected with the inlet of the second pipeline 2; the outlet of the second pipeline 2 is connected with the inlet of the slurry storage tank 3 The adjustable automatic pressure relief valve 4 is installed at the mud outlet on the top of the mud storage tank 3 .

[0030] The drill pipe 200 passes through the pipe hole of the orifice pipe 100 , that is, the first pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com