Semi-closed mud pressure maintaining and circulation technique in confined water stratum drilling construction

A confined water, semi-closed technology, applied in earth-moving drilling, wellbore/well components, flushing wellbore, etc., can solve the problems of unstable mud pressure, sand gushing, difficulty in forming the balance between mud and formation water and soil pressure, etc. Achieve the effect of ensuring normal propulsion, avoiding disturbance effects, and reducing soil erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to clearly illustrate the scheme of the present invention, preferred embodiments are given below and described in detail with reference to the accompanying drawings.

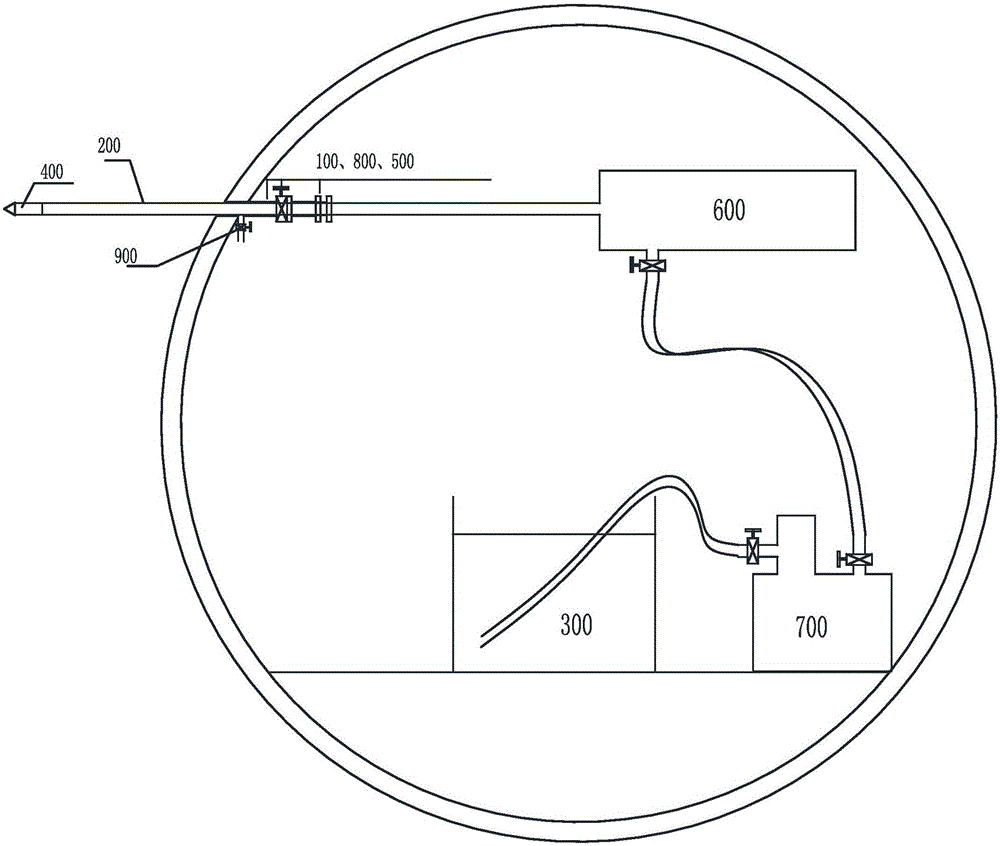

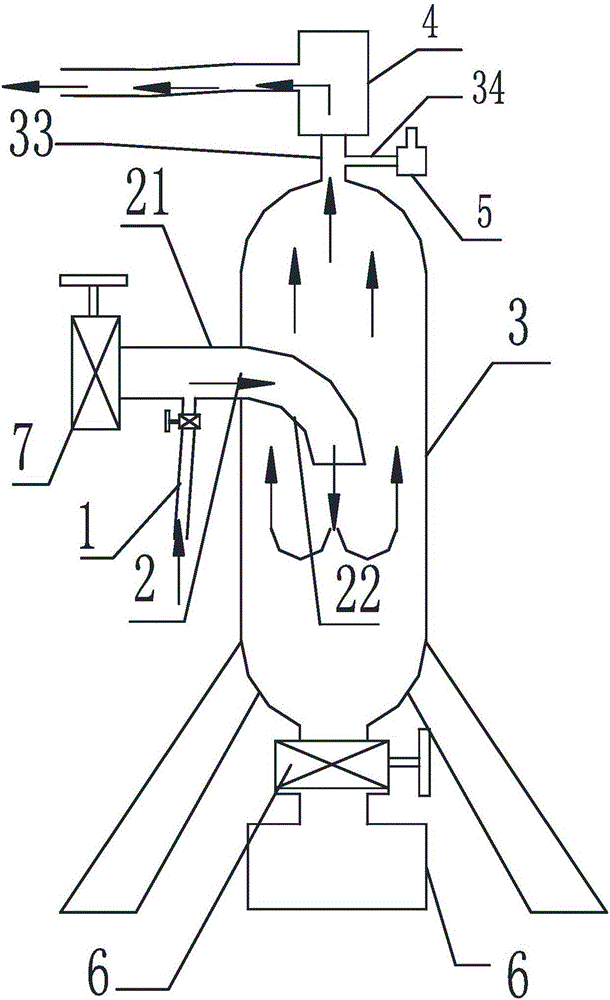

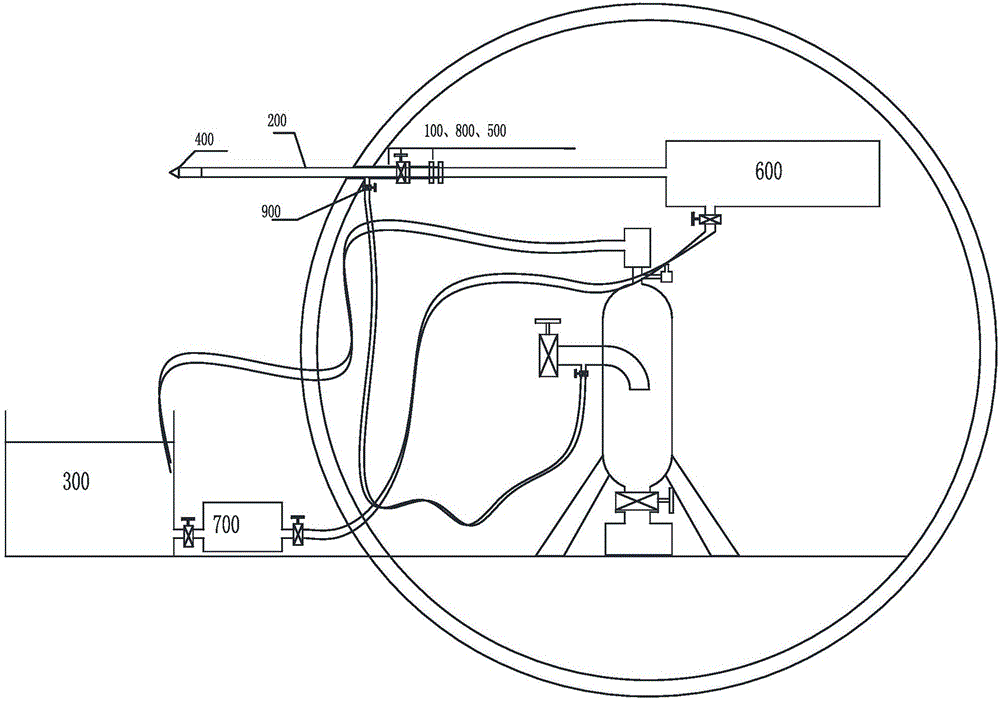

[0035] Such as image 3 As shown, the semi-closed mud pressure-maintaining circulation process for borehole construction in confined water strata in this embodiment includes the following steps:

[0036] (A) Install drilling rig 600, mud tank 300, mud pump 700, orifice sealing device and solid-liquid separation device respectively;

[0037] (B) Connect the mud outlet of the mud pool 300 with the mud inlet of the mud pump 700, and connect the mud outlet of the mud pump 700 with the mud inlet of the drilling rig 600;

[0038] (C) The mud inlet of the solid-liquid separator is in communication with the mud outlet of the orifice sealing device, and the mud outlet of the solid-liquid separator is in communication with the mud inlet of the mud tank 300;

[0039] (D) The pressure threshold in the solid-liquid se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com