Duplex cyclone pneumatic slag taker special for metallic magnesium

A metal magnesium, compound technology, applied in the direction of metal processing equipment, mechanical cleaning, charge manipulation, etc., can solve problems such as low efficiency, and achieve the effect of improving work efficiency and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

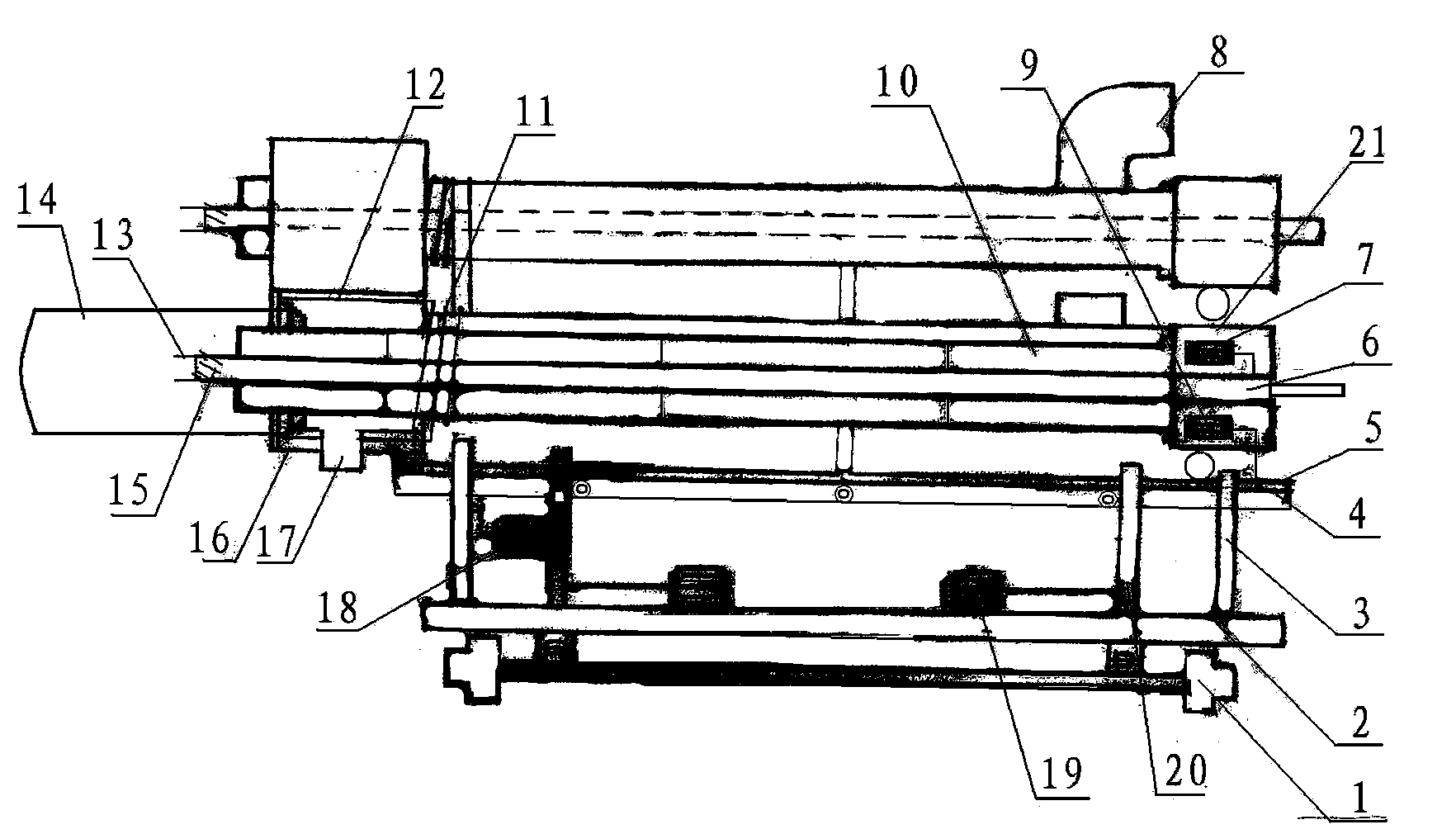

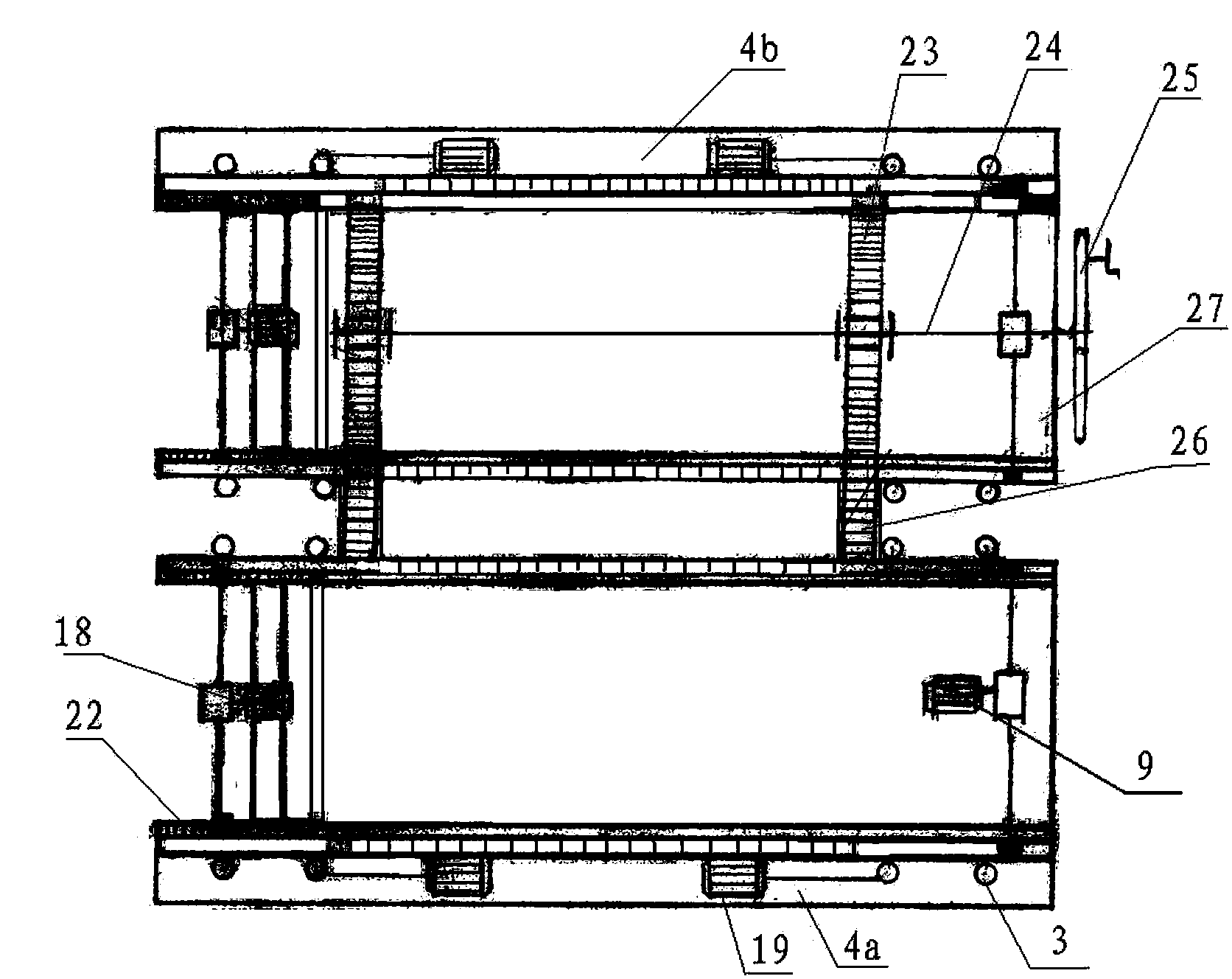

[0011] As shown in the figure, a compound swirling pneumatic slag removal machine dedicated to metal magnesium, the structure includes: walking wheel 1, machine base 2, lifting motor 19, lifting platform 4, such as figure 2 As shown, there are two lifting platforms 4, which are respectively left lifting platform 4a and right lifting platform 4b; see figure 1 , where the left lifting platform 4a is provided with a track 5, on which is a walking frame 21, on which the walking frame 21 is equipped with a Roots wind working tube 10, a compressed air working tube 6, a Roots wind working tube 10 and a compressed air working tube 6 Socketing, a traveling motor 9 and a rotating motor 7 are installed in the traveling frame 21. The traveling motor 9 drives the Roots wind working tube 10 to move, and the rotating motor 7 drives the compressed air working tube 6 to rotate; the front end of the compressed air working tube 6 is a stirring head 13. Rotating blades 15 are arranged on the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com