A shield machine disc-shaped hob tool changing mechanical arm end effector

A technology of end effector and disc hob, which is applied to manipulators, program-controlled manipulators, mining equipment, etc., can solve problems such as danger, achieve the effects of convenient operation, improve construction efficiency, and reduce construction risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

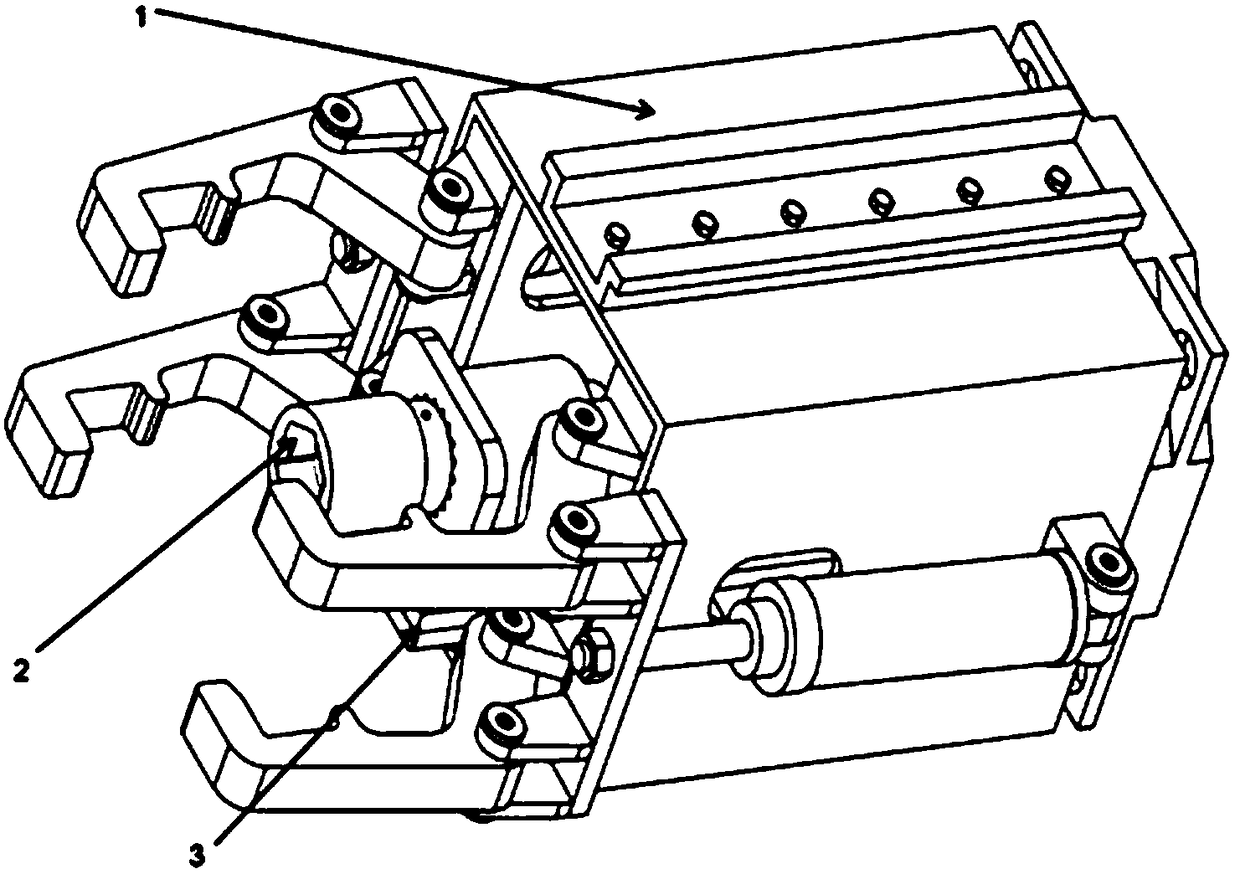

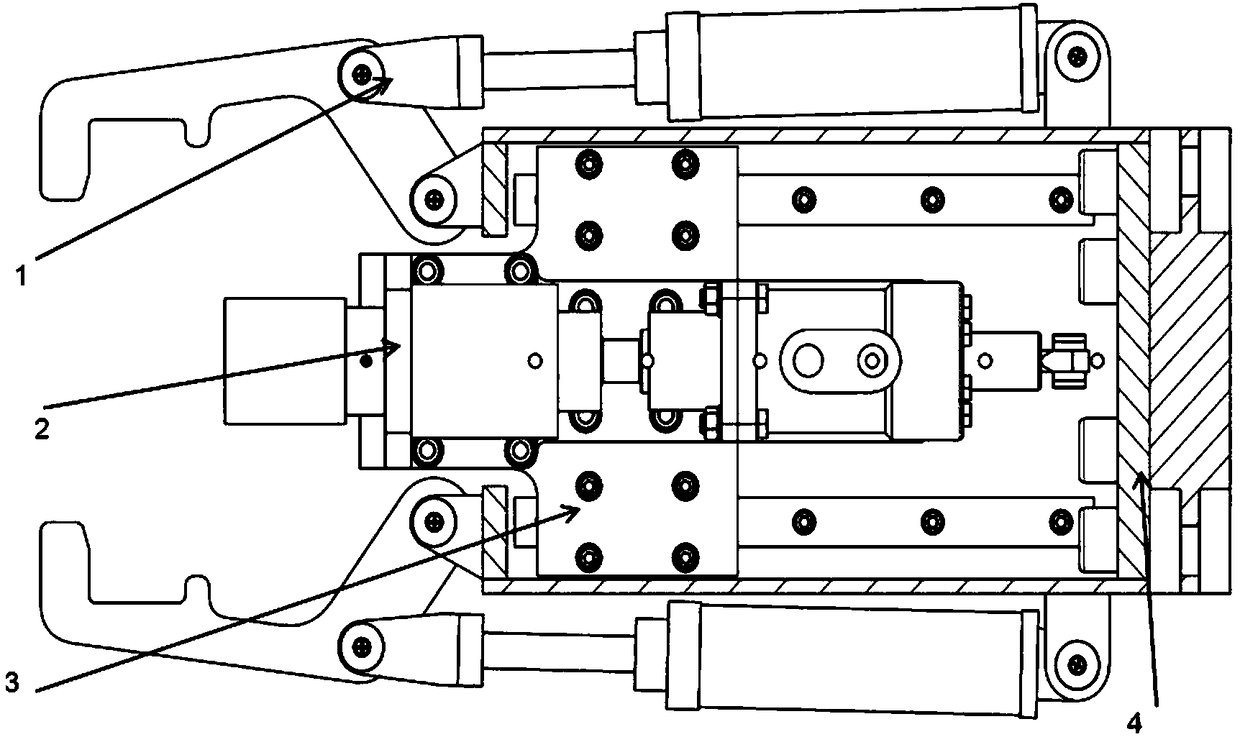

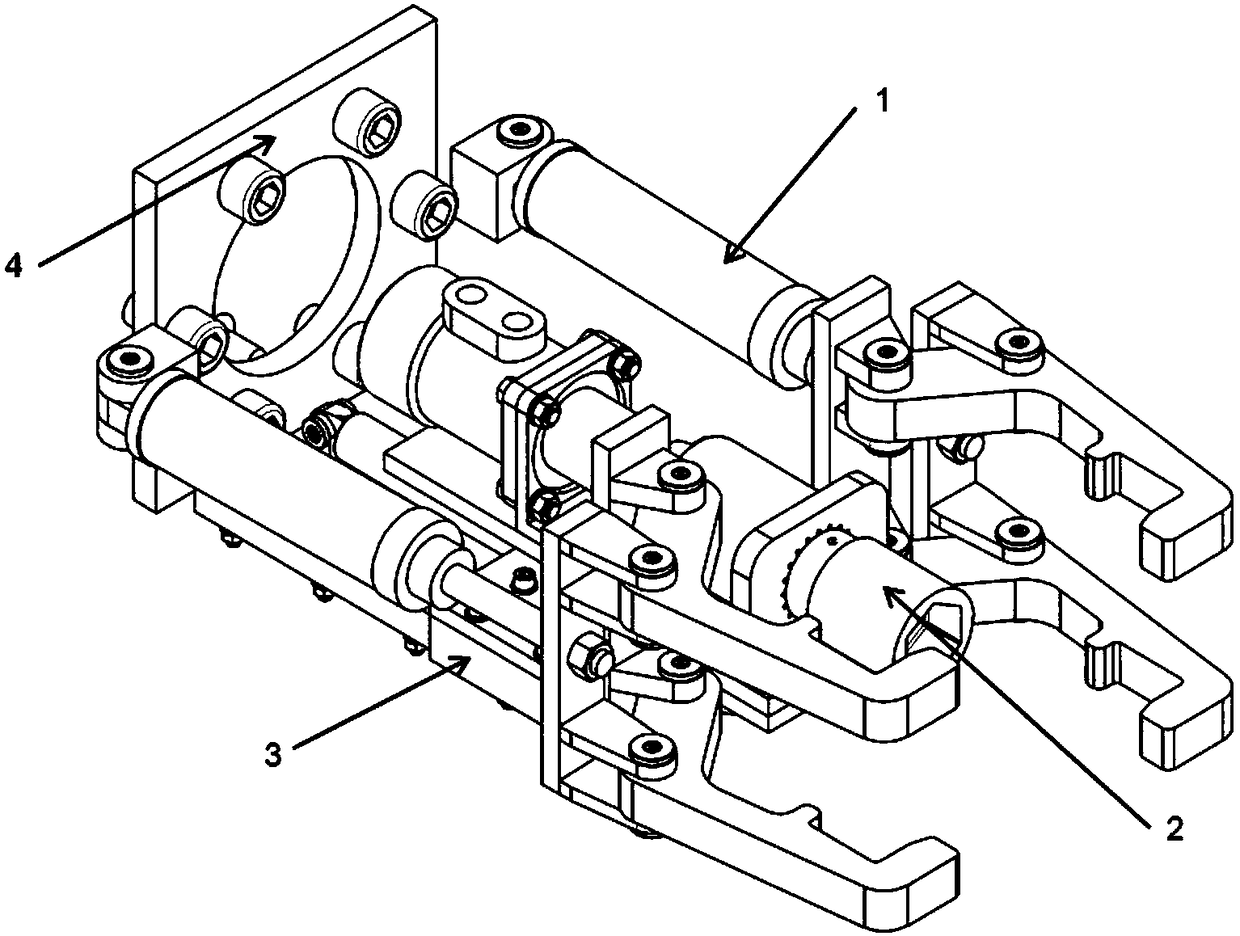

[0039] Such as Figure 1-Figure 8 The end effector of a disc-shaped hob tool changing mechanical arm of a shield machine is shown, including an end effector main body module 1, a bolt disassembly and fixing module 2 and an axial movement module 3;

[0040] The bolt disassembly and fixing module 2 is fixed on the axial movement module 3 by bolts, and the axial movement module 3 is connected to the main body module 1 of the end effector by bolts, and the whole actuator can be connected with the mechanical arm through quick change.

[0041] The end effector body module 1 includes a quick change mounting plate 4, a quick change tool side 5, an end effector hanger 6, an end effector frame 7, a pin shaft b8, a finger earring a9, a pin shaft a10, a finger 11, a finger Mounting plate 12, finger drive plate 13, finger earring b14, hydraulic cylinder a15, hydraulic cylinder earring a16 and hydraulic cylinder pin a17;

[0042] The fingers are respectively connected to the finger earring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com