Eccentric gear connecting rod mechanism

A link mechanism and eccentric wheel technology, applied in electromechanical devices, mechanical equipment, control of mechanical energy, etc., can solve problems such as low transmission efficiency and poor eccentric adjustment ability, and achieve reduced load rate, movement path, and vibration reduction. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

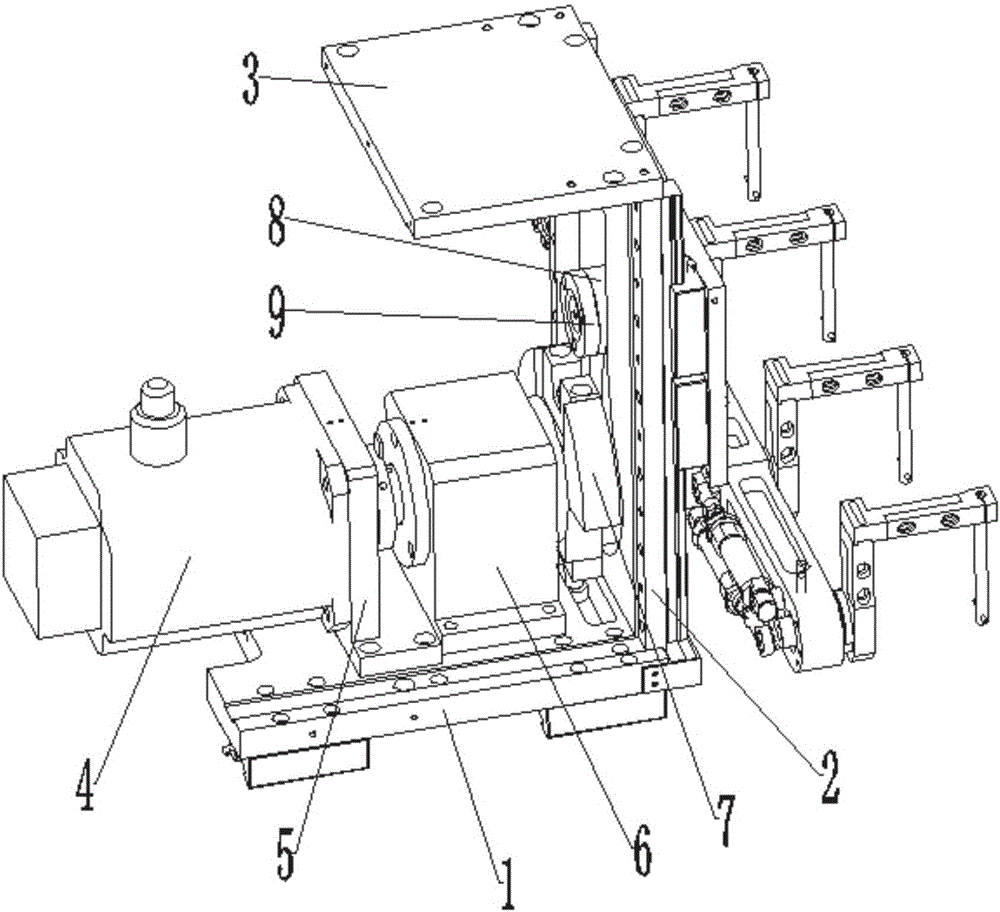

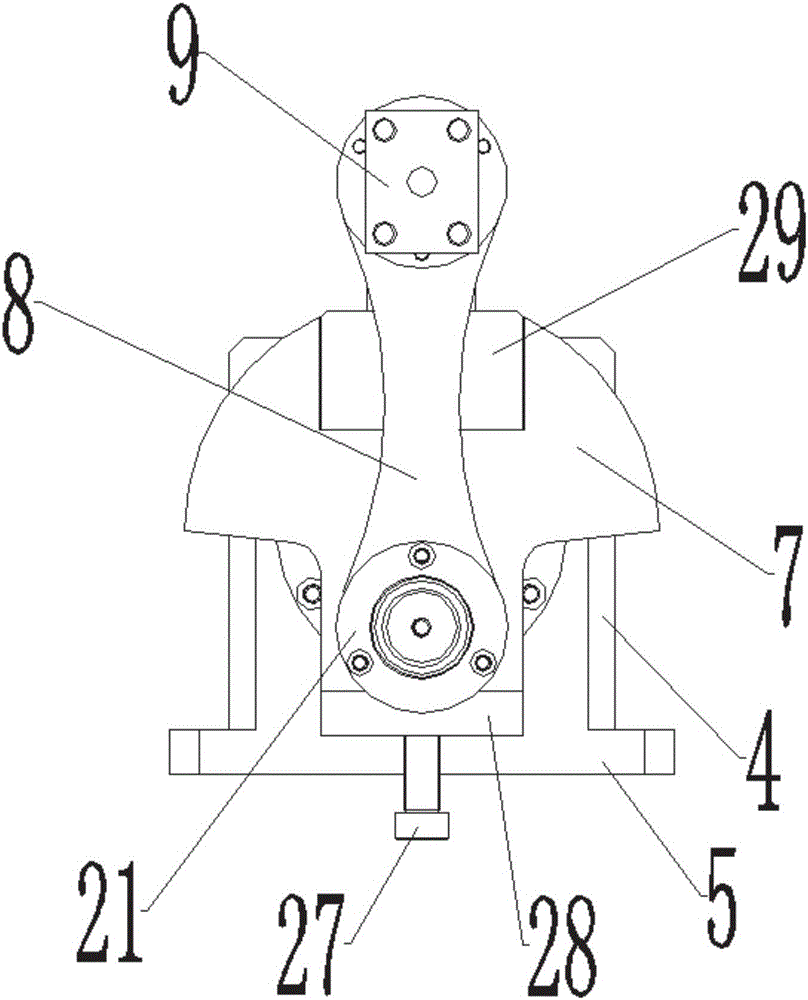

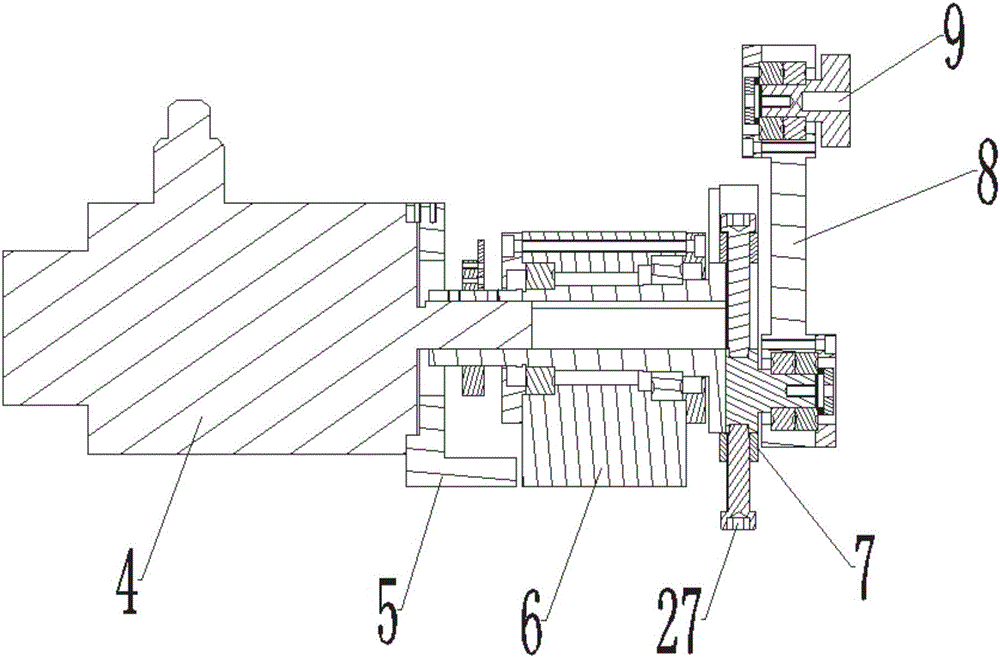

[0018] Such as Figure 1-4 As shown, the eccentric wheel linkage mechanism of the present invention includes a bottom plate 1, a side plate 2 and a top plate 3, the side plate 2 is vertically installed and fixed on one end of the bottom plate 1, the top plate 3 is arranged in parallel, and one end thereof is fixed on the side plate 2 the top of. Different from the prior art, the present invention adopts the connecting rod 8 assembly to realize linear motion, the surface of the base plate 1 is provided with the connecting rod 8 assembly and the drive motor 4 that drives the action of the connecting rod 8 assembly, and the drive motor 4 is arranged laterally , the surface of the base plate 1 is provided with a motor seat 5 for installing and fixing the drive motor 4, the left and right edges of the motor seat 5 are fixed on the surface of the base plate 1 by screws, and the connecting rod 8 assembly consists of an eccentric wheel mounting seat 6, an eccentric wheel 7, The conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com