Boiler wind supplying mechanism with small wind catchers

An air bucket and air supply technology, which is applied in the direction of combustion air/fuel supply, valve configuration, combustion method, etc., can solve the problems of inability to adjust the air coefficient reasonably, affecting the full combustion of fuel, and incapable of full combustion of fuel, etc. The uniformity of the horizontal air distribution of the grate, the use effect is not affected, and the sealing effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings. The following embodiments are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

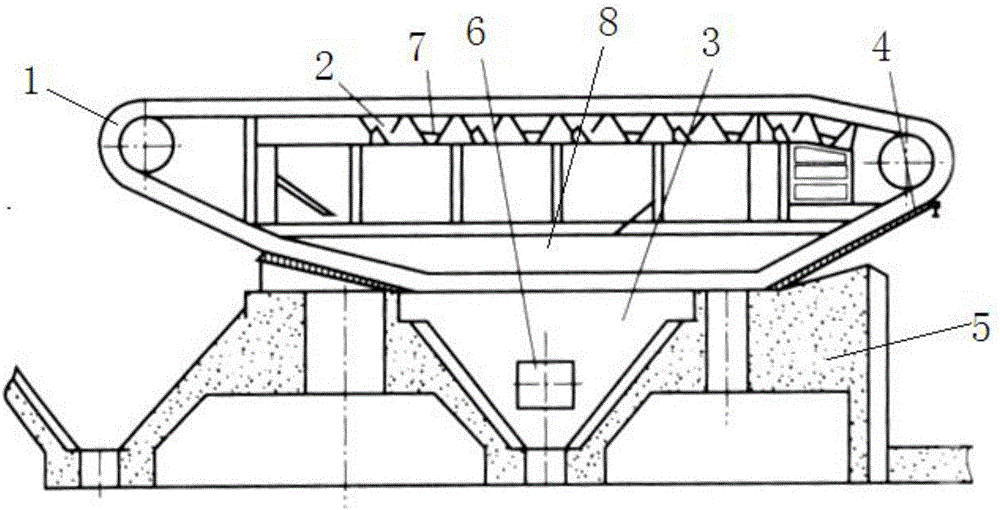

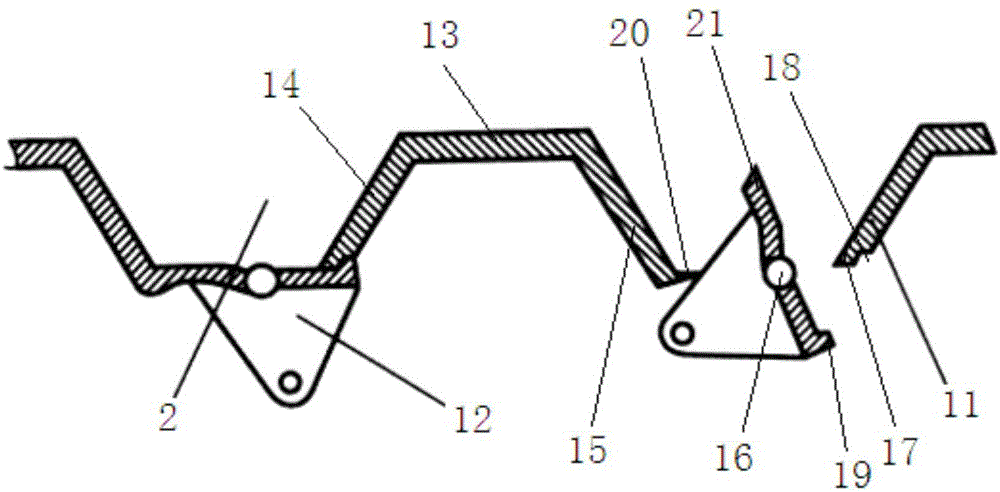

[0020] As shown in Figure 1-2, a boiler air supply mechanism with a small air hopper includes an air supply body 1, a small air hopper 2, a large air silo 3, and a sealing member 4. The air supply body is provided on the grate 5 1. One end of the air supply body 1 is provided with a large wind bin 3 located in the grate, and the large wind bin 3 has an inverted horn shape. An air inlet 6 is provided at the top of the large wind warehouse 3, and five groups of small wind buckets 2 are longitudinally provided at the other end of the air supply body 1, and each group of small wind buckets is provided with 10 small wind buckets 2, and each An air-regulating door 7 is provided on the air hopper 2, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com