Making method of range hood lock catch support drawing installing support

A technology for installing a bracket and a range hood, which is applied in the directions of removing oil fume, heating mode, lighting and heating equipment, etc., can solve the problems of affecting the appearance effect, wasting materials, poor reliability of the bracket, etc., and achieves shortening of production processes, cost reduction, positioning precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the patent of the present invention will be further described.

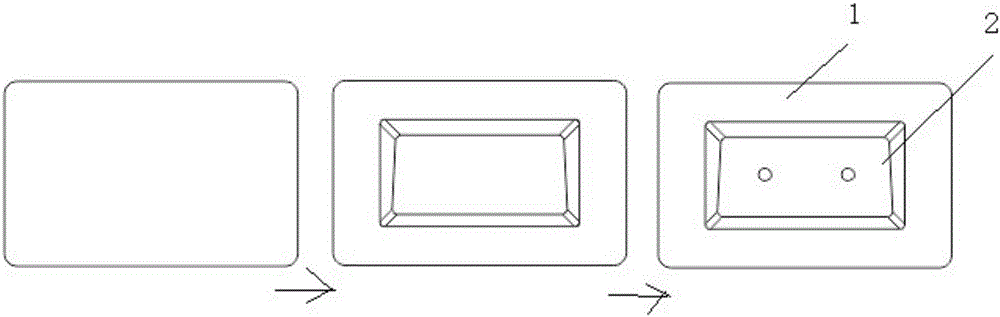

[0021] Such as figure 1 As shown, the range hood lock mounting bracket of the present invention is prepared by the process of body material -->> stretching the bracket boss -->> punching the lock mounting hole.

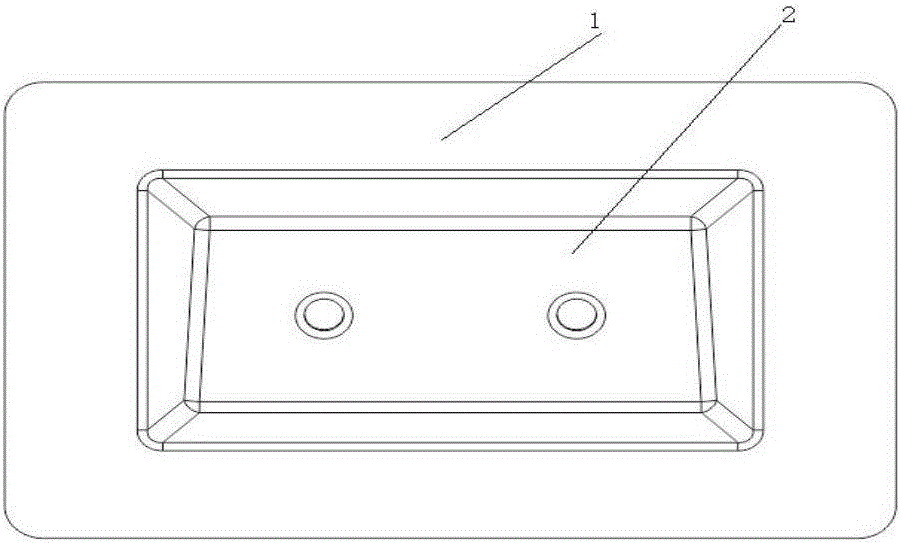

[0022] Such as Figure 2-Figure 8 As shown, the bracket 2 is formed by a boss stretched out from the body 1 of the range hood, on which there are punched holes, the number of which is two, and the lock buckle 3 is fixed on the Punch on.

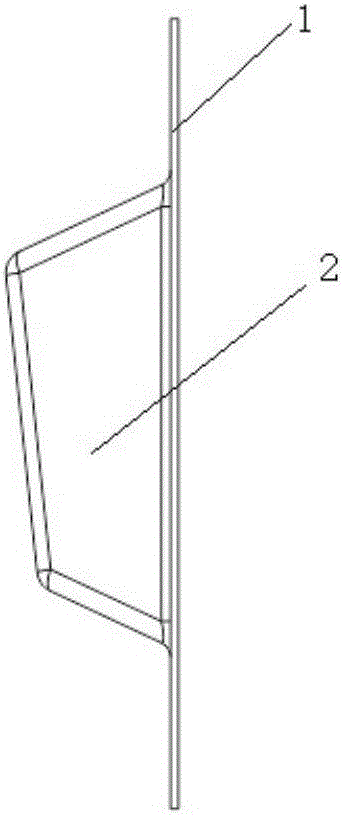

[0023] Such as Figure 9 , Figure 10 As shown, the traditional support is welded in the shape of a few characters, and the positioning of the welded support in the shape of a few characters is difficult, easy to store oil, and waste materials. Compared with the present invention, the present invention has obvious advantages.

[0024] The above is only the preferred embodiment of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com