Manufacturing process and application of a large-scale gasket metal skeleton without welding technology

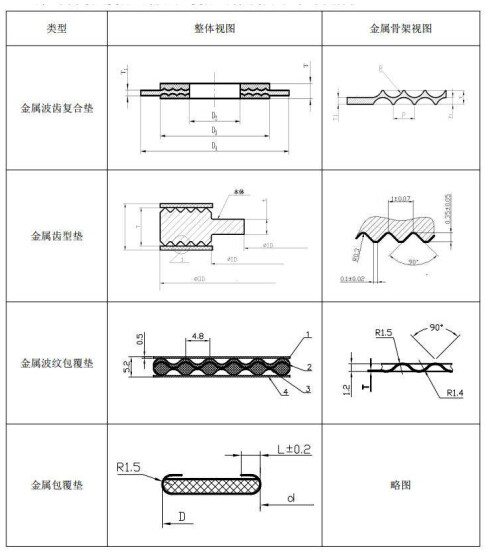

A technology of metal skeleton and manufacturing process, which is applied in metal rolling and other directions, can solve problems such as leakage, welded joint fracture, sealing gasket cannot meet the uniform contact of flange surface, etc., and achieve the effect of short process flow and no welding points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments:

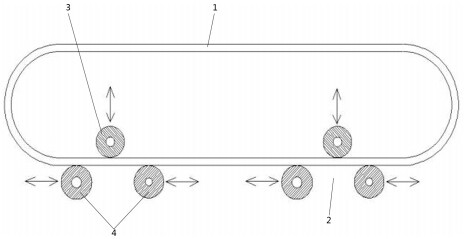

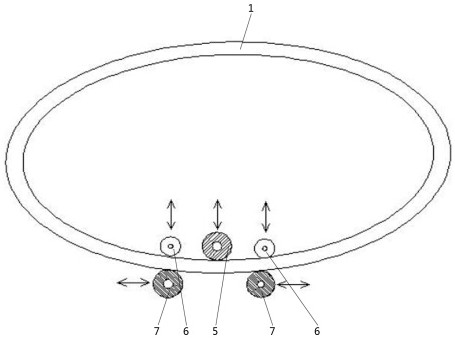

[0036] see Figure 2 to Figure 4 , the present invention provides a large-scale gasket metal skeleton without welding technology manufacturing process, including the following steps:

[0037] 1) Material, according to the thickness of the metal sheet, we adopt different heights of material acquisition. The metal sheet with a thickness of 0-10mm uses a laser cutting machine to take the elliptical ring; the metal sheet with a thickness of 11-25mm uses a flame cutting equipment to take the elliptical ring; For metal plates with a thickness of more than 26mm, use water jet cutting equipment to take elliptical rings.

[0038] 2) Cold simmering and deformation, cold working the elliptical ring to a ring with a specified outer diameter to obtain a ring body;

[0039] 3) High temperature forming, using hot extrusion forming device to heat t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com