Circularly-heating electric water heater with thermal compensation function

A circulating heating and electric water heater technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of accelerating the aging and decline of electric heating tubes, affecting the life of electric heating tubes, and unable to eliminate leakage problems, etc., to achieve The effect of thermal compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

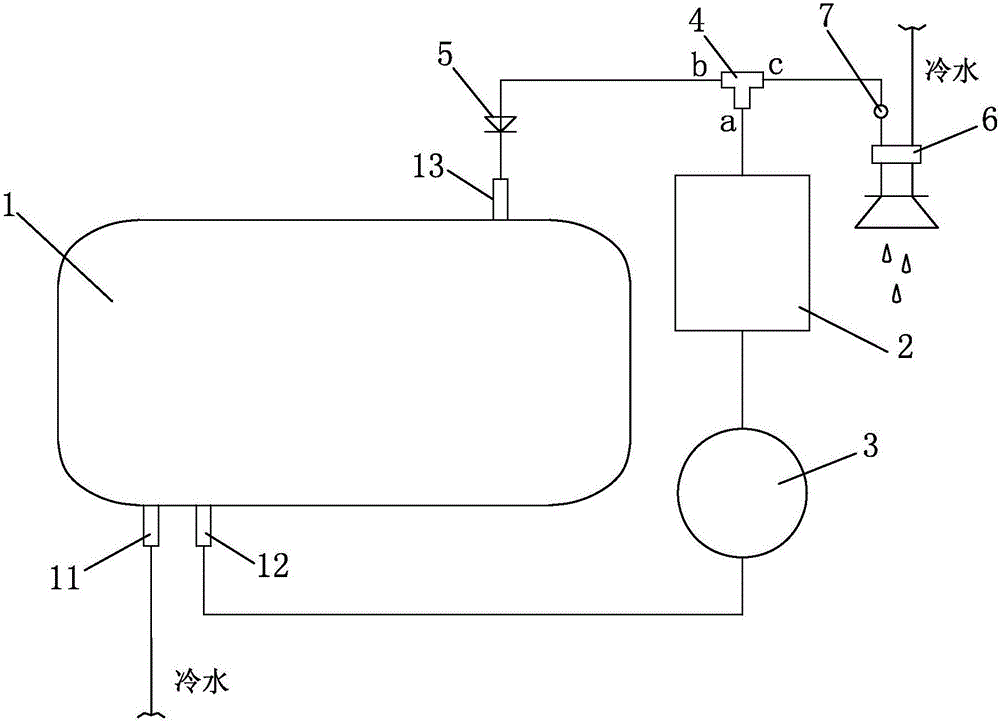

[0020] see figure 1 , the circulating heating electric water heater with thermal compensation function, comprising a water tank 1, an external circulation heating assembly and a three-way valve 4, the water tank 1 is provided with a cold water inlet 11 for replenishing water for the water tank 1, and an external circulation outlet 12 And the outer circulation water inlet 13, the outer circulation water outlet 12, the outer circulation heating assembly, the three-way valve 4 and the outer circulation water inlet 13 are sequentially connected to form an outer circulation heating circuit, wherein the water inlet a of the three-way valve 4 and the first The water outlet b is connected between the outer circulation heating assembly and the outer circulation water inlet 13, and the second water outlet c of the three-way valve 4 is a hot water outlet, which can be directly connected to the hot water inlet end of the outlet water mixing valve 6, and the outlet water mixing The cold wa...

no. 2 example

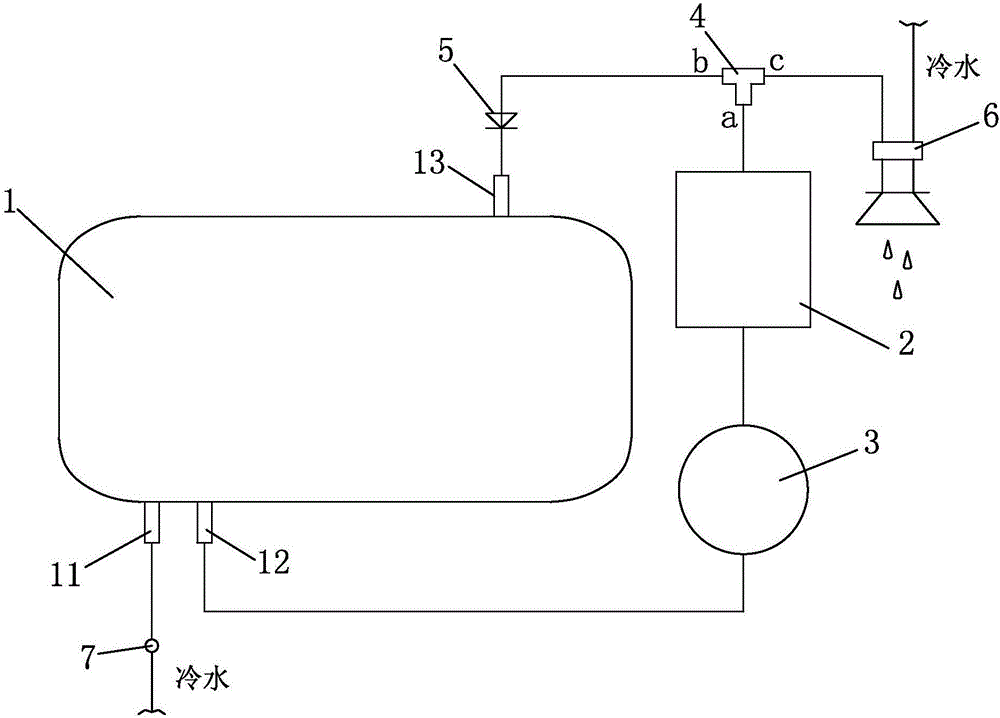

[0032] see figure 2 , the electric water heater of circulating heating with thermal compensation function is provided with a flow sensor 7 at the cold water inlet 11, which also enables the electric water heater to accurately judge whether it is in a hot water outlet state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com