Template detection device

A template detection and rack technology, which is used in measurement devices, optical testing of flaws/defects, and material analysis by optical means, can solve the problems of observer fatigue, affect physical health, and reduce work efficiency, and achieve convenient observation, The effect of reducing fatigue and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

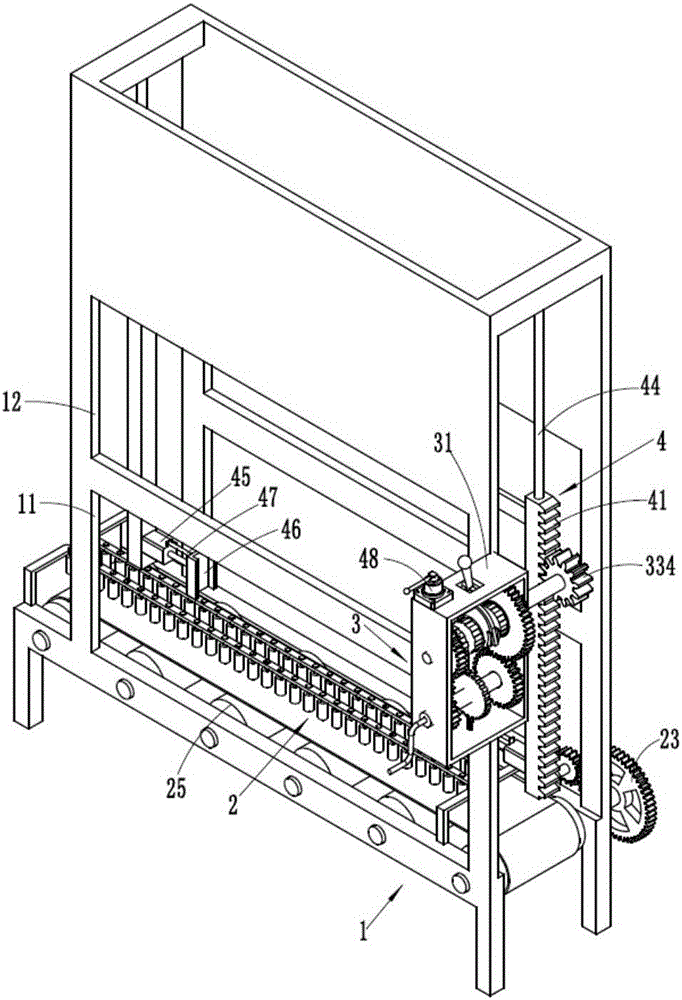

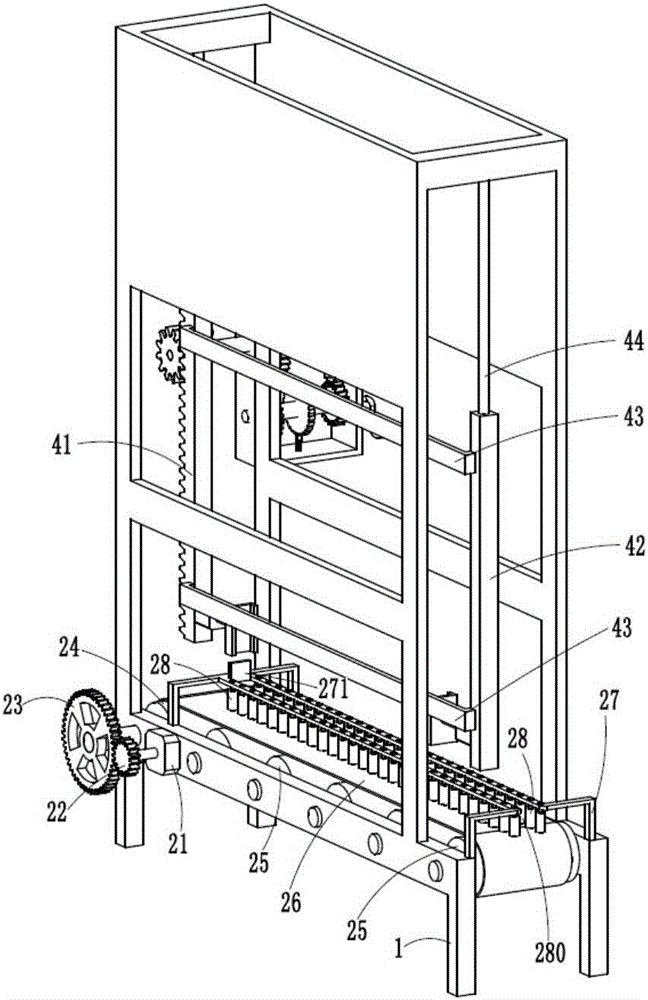

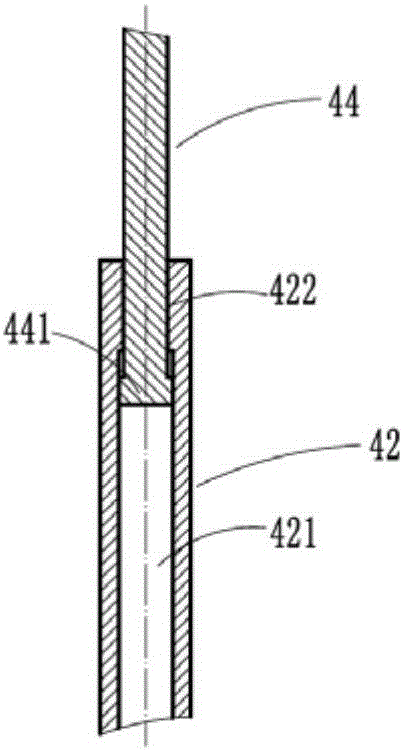

[0031] Examples, see as Figure 1 to Figure 7 As shown, a template detection device includes a frame 1, a lateral movement mechanism 2, a longitudinal movement mechanism 4 and a drive mechanism 3. The lateral movement mechanism 2 is installed at the bottom of the frame 1, and the longitudinal movement mechanism 4 is installed at the frame. Inside 1 , the second bracket 31 of the drive mechanism 3 is fixed on the right side of the frame 1 , and the lift drive gear 334 of the drive mechanism 3 meshes with the lift rack 41 of the longitudinal movement mechanism 4 .

[0032] More specifically, the lateral movement mechanism 2 includes a drive motor 21 fixed on the frame 1, the output shaft of the drive motor 21 is fixedly connected with a drive pinion 22, the drive pinion 22 meshes with the large gear 23, and the large gear 23 It is fixed on the extension shaft of the rear end of the conveying roller 24. The left end of the conveying roller 24 is provided with a plurality of suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com