Color film substrate and preparation method thereof and display panel and display

A color film substrate and display panel technology, which is applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of angular difference, affecting the display effect, and uneven thickness of the liquid crystal cell of the display panel, so as to avoid angular difference and light leakage , optimize the display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

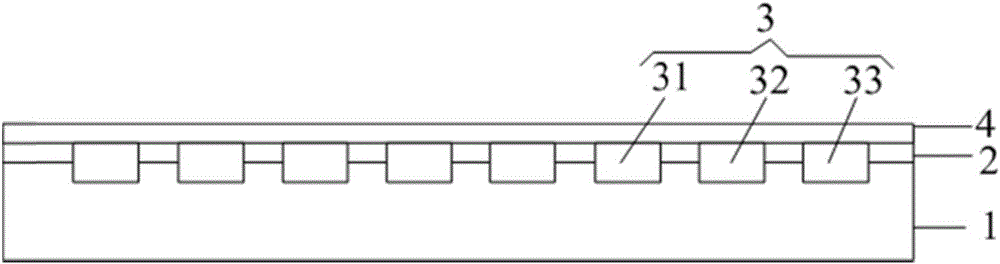

[0024] Meanwhile, according to the second aspect of the present invention, a method for preparing a color filter substrate is also provided, the method comprising the following steps: S1, forming a black matrix with a desired pattern on a base substrate; S2, using the black matrix The matrix is a mask to etch the base substrate, and a corresponding pixel groove is formed at the opening of the base substrate corresponding to the black matrix pattern; S3, filling the pixel groove and the opening of the black matrix pattern, forming a pixel unit whose upper surface is flush with the upper surface of the black matrix; and S4 , forming a conductive layer on the surface of the black matrix and the pixel unit.

[0025] The preparation method of the above-mentioned color filter substrate provided by the present invention is simple in process, easy to implement, and suitable for large-scale production. The method uses the black matrix as a mask to etch the base substrate to form pixe...

Embodiment 1

[0042] Preparation of color filter substrate:

[0043] S1. Use glass with a thickness of 0.5 mm (an AN100 model product from AGC Company) as a base substrate;

[0044] S2, prepare a black matrix photoresist with a solid content of 15wt% (a product of the BK-6180SL model from TOK Company); coat the black matrix photoresist on the base substrate to form a thickness of 10 μm The black matrix photoresist layer, the substrate substrate coated with the black matrix photoresist layer is placed in exposure equipment (commercially available from Japan DNK company RZ-1300IXF / C model), at 23 ° C, 40MJ / cm 2 Intensity, exposure for 15s, forming a black matrix precursor with a black matrix pattern, drying at 230 ° C for 30 minutes, forming a black matrix (thickness is 1.5μm);

[0045] S3. Prepare a hydrofluoric acid solution with a HF content of 5 wt%, use the black matrix as a mask, and use the aforementioned hydrofluoric acid solution to etch the base substrate at 35° C. for 45 s, and th...

Embodiment 2

[0052] Preparation of display panel: the display panel includes an array substrate, a color filter substrate, and a liquid crystal layer disposed therebetween, wherein the color filter substrate adopts the color filter substrate prepared in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com