Backlight module and display device

A technology for backlight modules and light source components, applied in optics, nonlinear optics, instruments, etc., can solve the problems of uneven light output, difficulty in large size, and poor thinning, and achieve the effect of uniform light output and high display quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present application are described below in conjunction with the accompanying drawings.

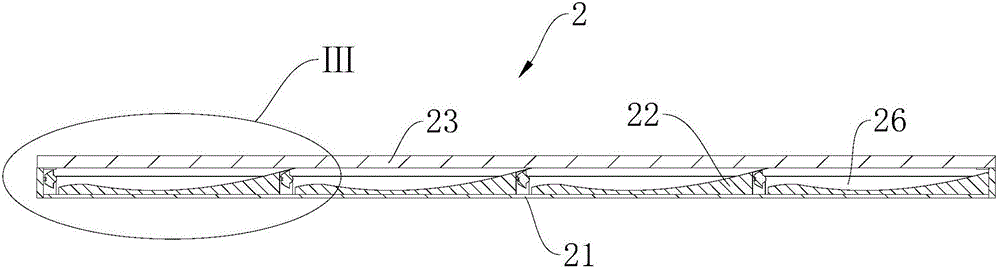

[0034] Please also refer to Figure 1 to Figure 4 , the embodiment of the present invention provides a display device 100 . The display device 100 includes a stacked display panel 1 and a backlight module 2 , the backlight module 2 is used to provide a backlight for the display panel 1 . The display panel 1 may be a liquid crystal display panel, and the display device 100 is a liquid crystal display.

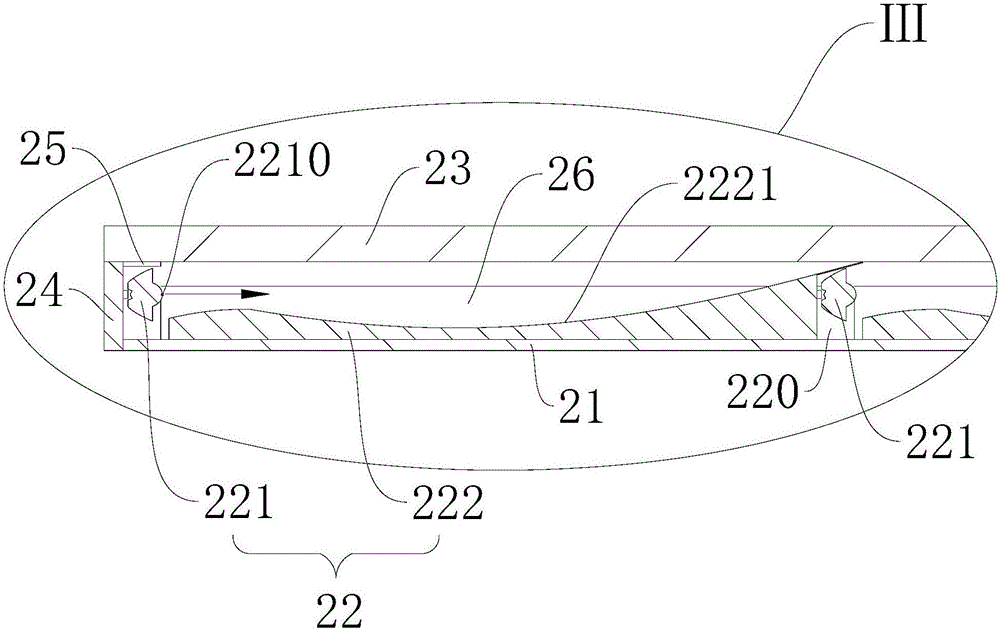

[0035] The backlight module 2 includes a backplane 21 and a plurality of light emitting units 22 spliced in sequence and fixed on the backplane 21 . Each of the light emitting units 22 includes a light source assembly 221 and a light guide 222 disposed adjacent to the light source assembly 221 . The light guide 222 includes a main part 223 and an extension part 224, the main part 223 is fixed to the backboard 21, the main part 223 has a first reflective surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| beam angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com