Shaft-distance-adjustable double-shaft synchronous fastening device capable of realizing operation without power cut

A fastening device, wheelbase technology, applied in the direction of needle tip/slotted plate contacts, circuits, electrical components, etc. used to penetrate insulated wires/cable core wires, can solve the problem of difficulty in ensuring synchronous or alternate tightening of two Nut, temperature rise, puncture blade skewed needle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

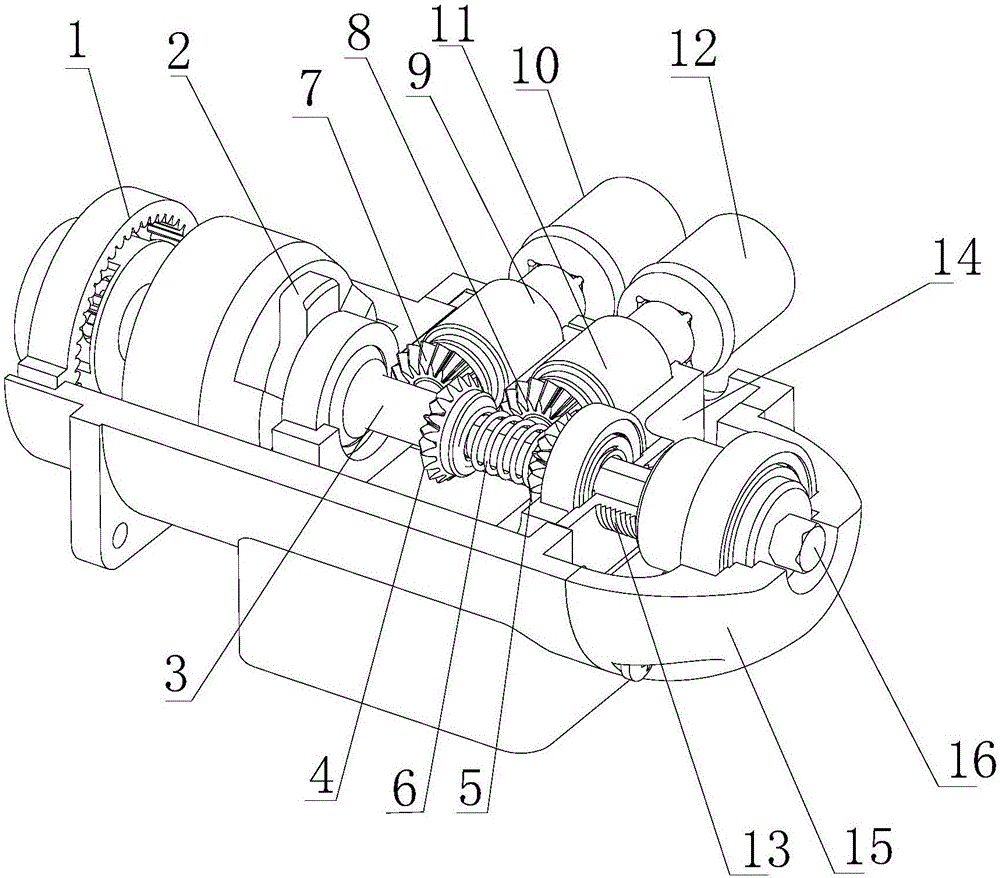

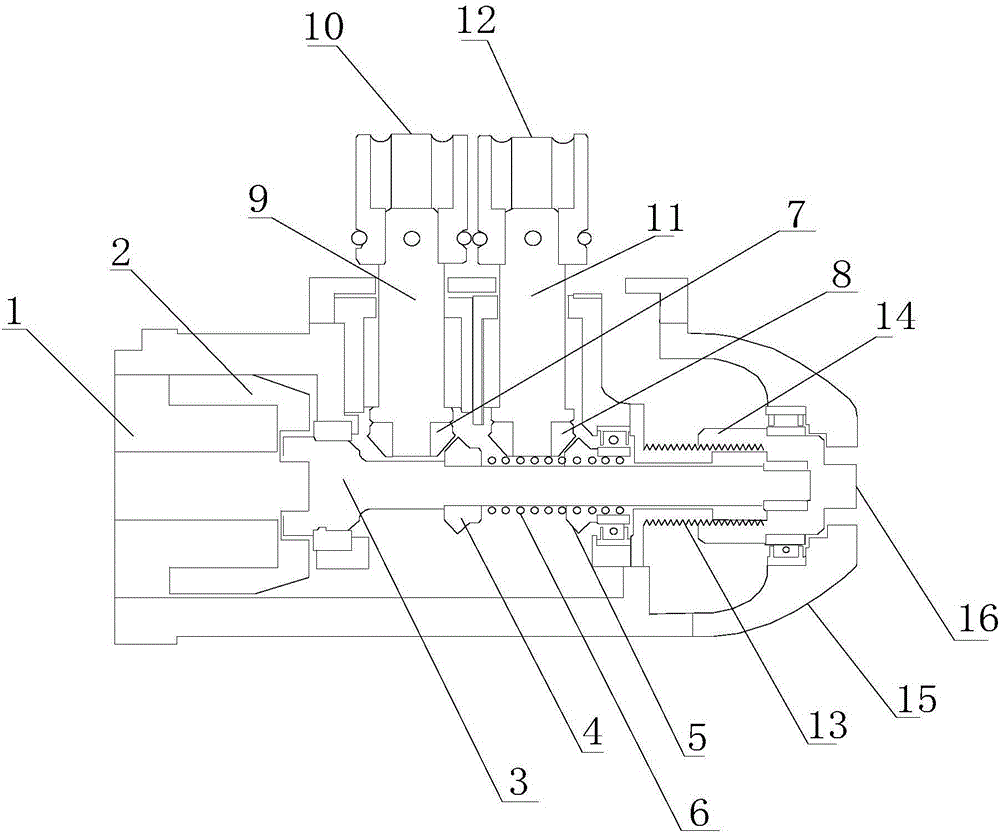

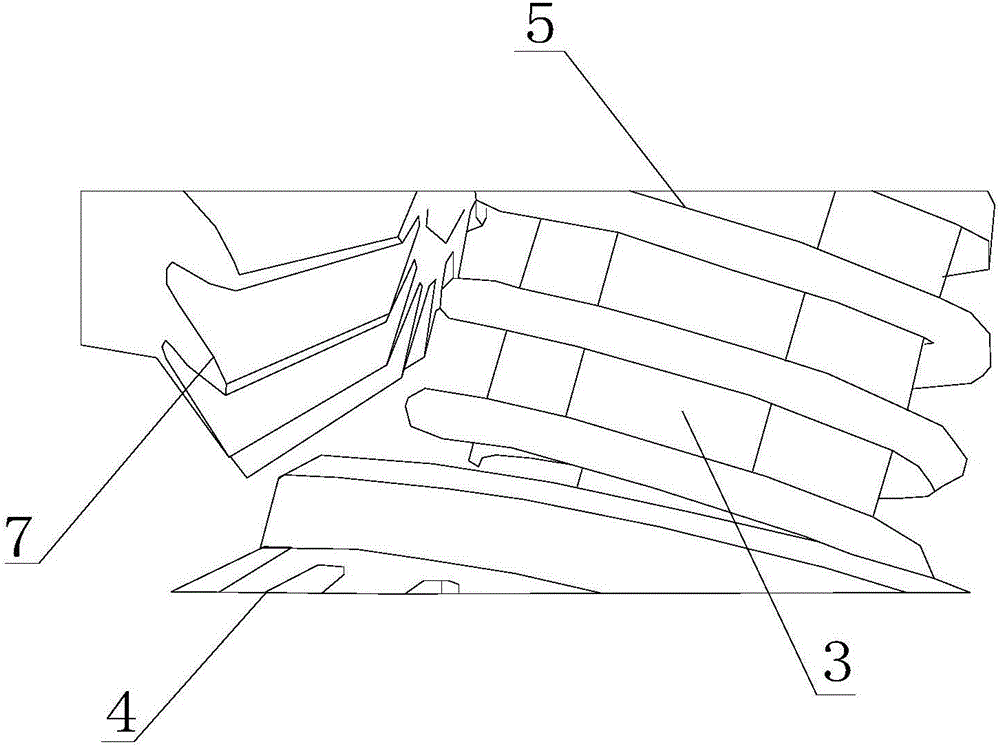

[0017] Such as figure 1 , figure 2 As shown, the purpose of the present invention is to provide a dual-axis synchronous fastening device with adjustable wheelbase for non-stop operation, including a motor 1, a striking shaft 3, a first output shaft 9 and a second output shaft 11, the motor 1 By driving the striking block 2 to apply force to the striking shaft 3 to rotate, the striking shaft 3 is covered with a first striking gear 4 and a second striking gear 5, and a spring 6 is provided at the interval between the two gears, and the second striking gear A striking gear 4 and a second striking gear 5 drive the first output gear 7 and the second output gear 8 respectively in the vertical direction, and the first output gear 7 and the second output gear 8 are externally connected to the first output shaft 9 and the second Two output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com