Direct-current induced draft motor

A technology for suction motors and motor housings, which is applied to electrical components, electromechanical devices, and electric components. The effect of air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

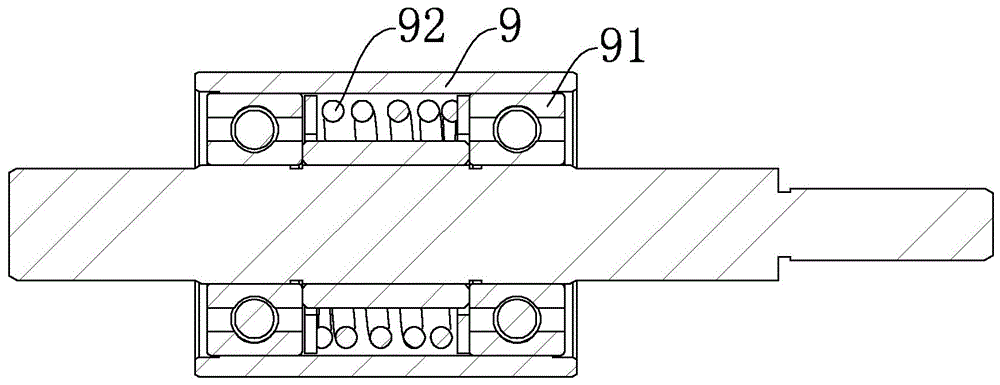

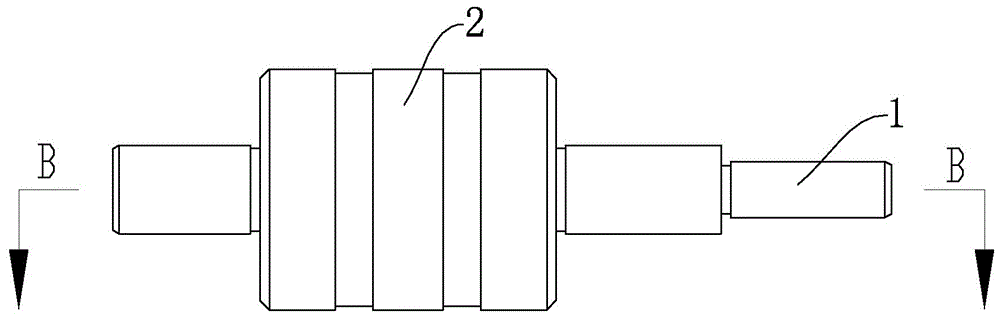

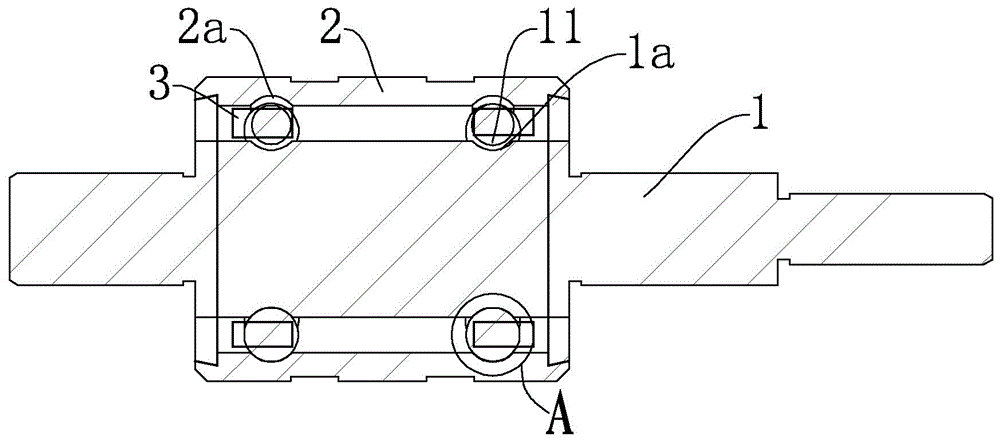

[0027] Figure 1 to Figure 7 Shown is the structural representation of the present invention.

[0028] The reference signs therein are: rotating shaft 1, first ball groove 1a, first axial section 1b, first arc center 1c, ball 11, mounting sleeve 2, second ball groove 2a, second axial section 2b, Second arc center 2c, cage 3, impeller 4, bottom plate 41, upper cover 42, air inlet 42a, rotating blade 43, motor housing 5, front end face 51, shaft hole 51a, annular step 51b, wind guide Sheet 52, support body 53, fixed convex body 53a, wind guide side wall 53b, air guide channel 54, end cover 6, sleeve 9, bearing 91, spring 92.

[0029] A DC suction motor according to the present invention includes a motor housing 5 and a stator assembly and a rotor assembly arranged in the motor housing 5 . The rotor assembly includes a rotating shaft 1 on which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com