Low-frequency loudspeaker case device and production process

A loudspeaker and casing technology, which is applied in the field of low-frequency speaker casing devices and production processes, can solve the problems of inability to effectively resist external corrosion for a long time, poor bass effect of the speaker, and unchanged product appearance, and achieve good waterproof and dustproof, easy to operate, The effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

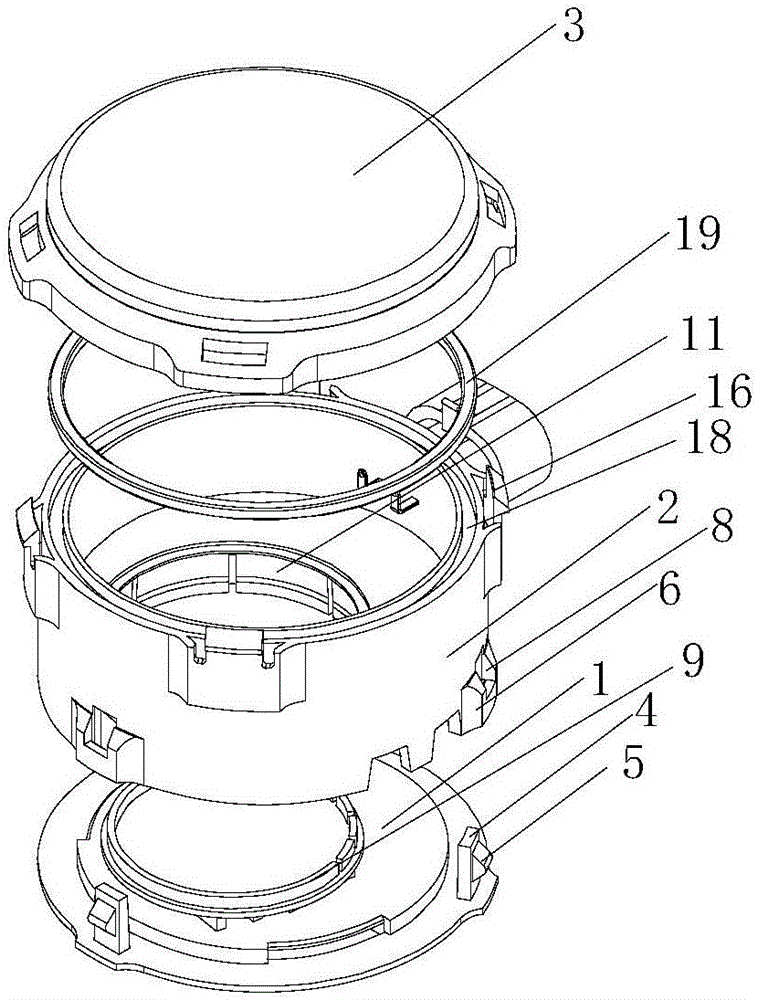

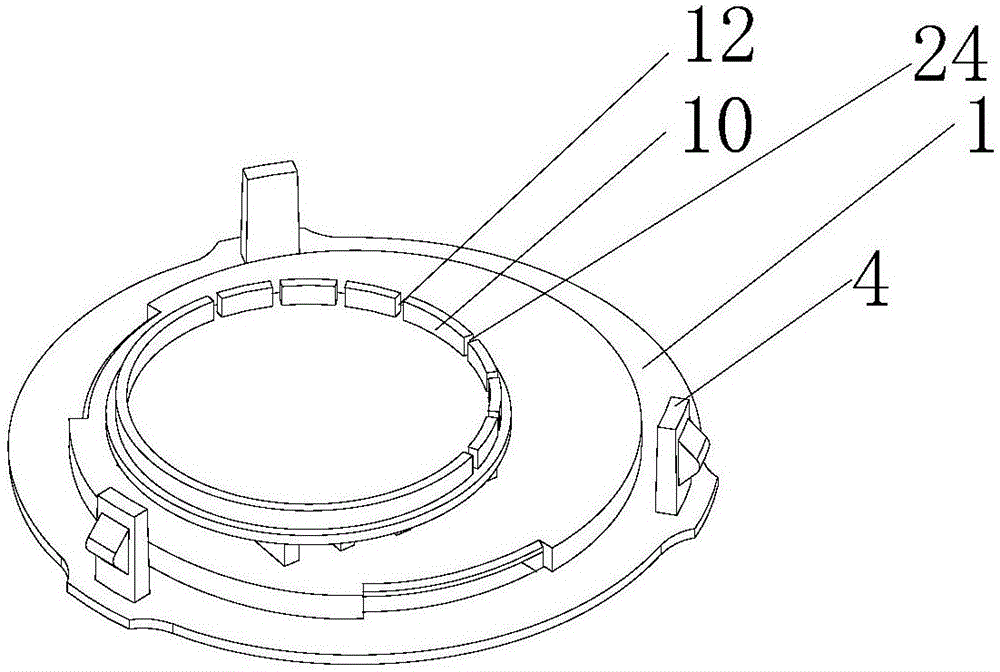

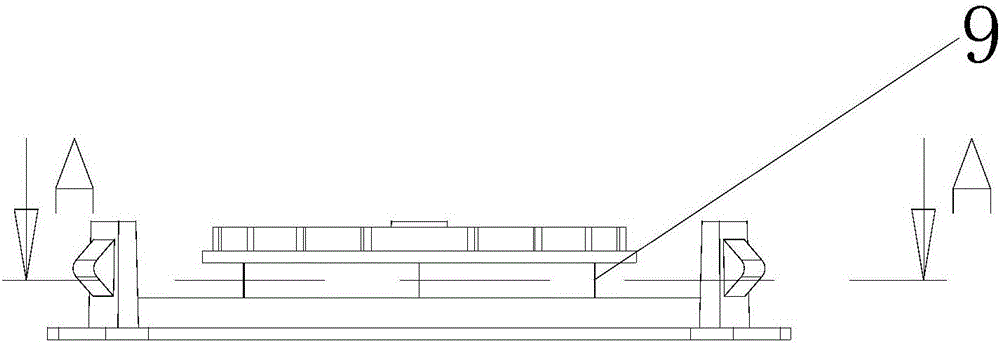

[0043] see figure 1 As shown, the low-frequency loudspeaker housing device includes an upper cover 1, a main body 2 and a lower cover 3 connected in sequence; it is characterized in that a plurality of insertion rods 4 are evenly distributed on the outside of the bottom surface of the upper cover, and the outer surface of the bottom end of the insertion rod is provided. There is a card edge 5; the upper side of the main body is provided with a number of flanges 6 used in conjunction with the insertion rod, and the flange is provided with a slot 7 for insertion of the insertion rod, and the bottom end of the slot is provided with a The hollow part 8 used; the top surface of the upper cover is provided with some first brackets 9, and the top surface of the first bracket is provided with a first baffle plate 10; the first baffle plate is provided with eight first sound holes 24. The bottom surface of the main body is eccentrically provided with a second baffle 11 used in conjunct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com